Filling system for fuel tank of aircraft

A filling system and aircraft technology, applied in the field of aircraft fuel tank filling system, can solve the problems that the oil detector cannot detect the oil in the tank, oil filling is time-consuming and laborious, and increases the risk of personnel exposure, so as to increase the pressure difference , improve efficiency, and accelerate the effect of emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

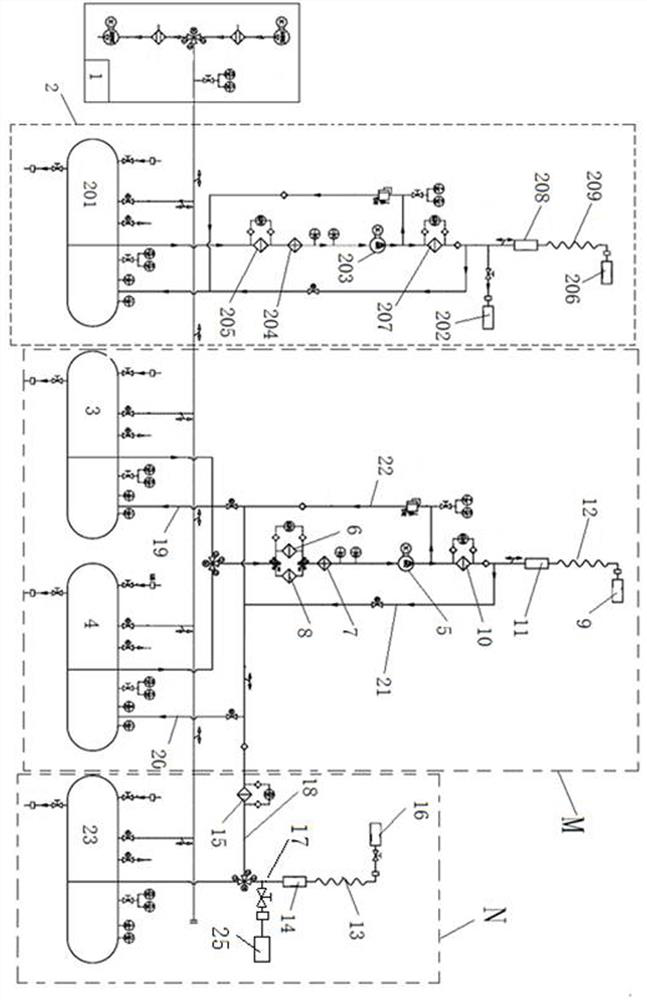

[0062] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. The components of the embodiments of the invention generally described and illustrated in the figures herein may be arranged and designed in a variety of different configurations.

[0063] like figure 1 , in order to improve the efficiency of aircraft filling, enhance the cleaning function of aircraft fuel tanks, and improve the quality and reliability of lubricating oil, the present invention proposes an integrated, multi-functional, convenient, efficient and economical aircraft lubricating oil filling system.

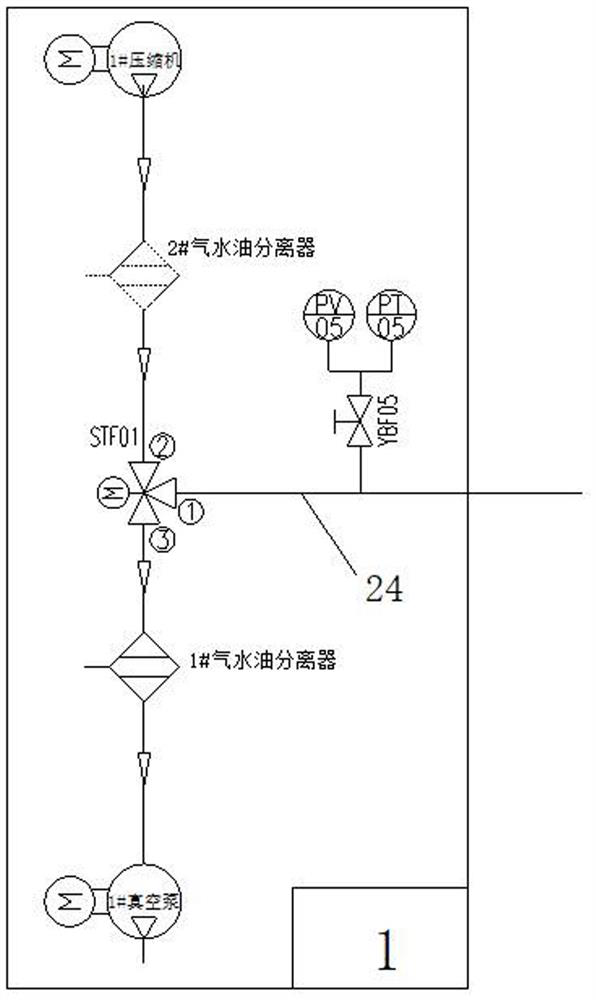

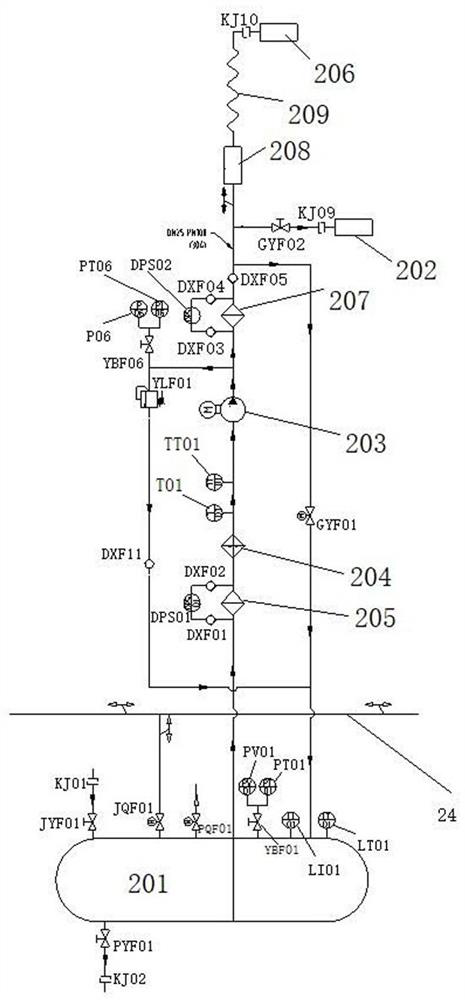

[0064] like figure 2 , Gas supply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com