Intelligent inspection and detection method for coal conveying belt conveyor in coal conveying bin area

A technology of intelligent patrol inspection and detection method, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of difficult safety accidents and responses, poor stability of visual detection algorithms, high technical barriers, etc., to avoid Significant losses, to achieve the effect of automatic temperature detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

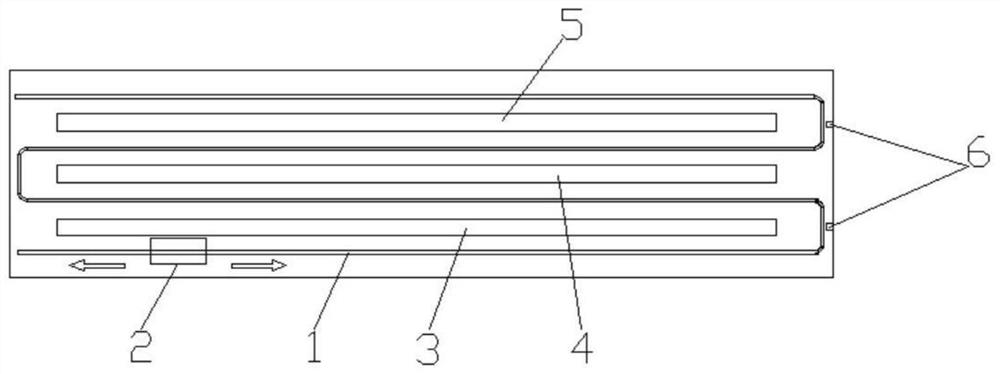

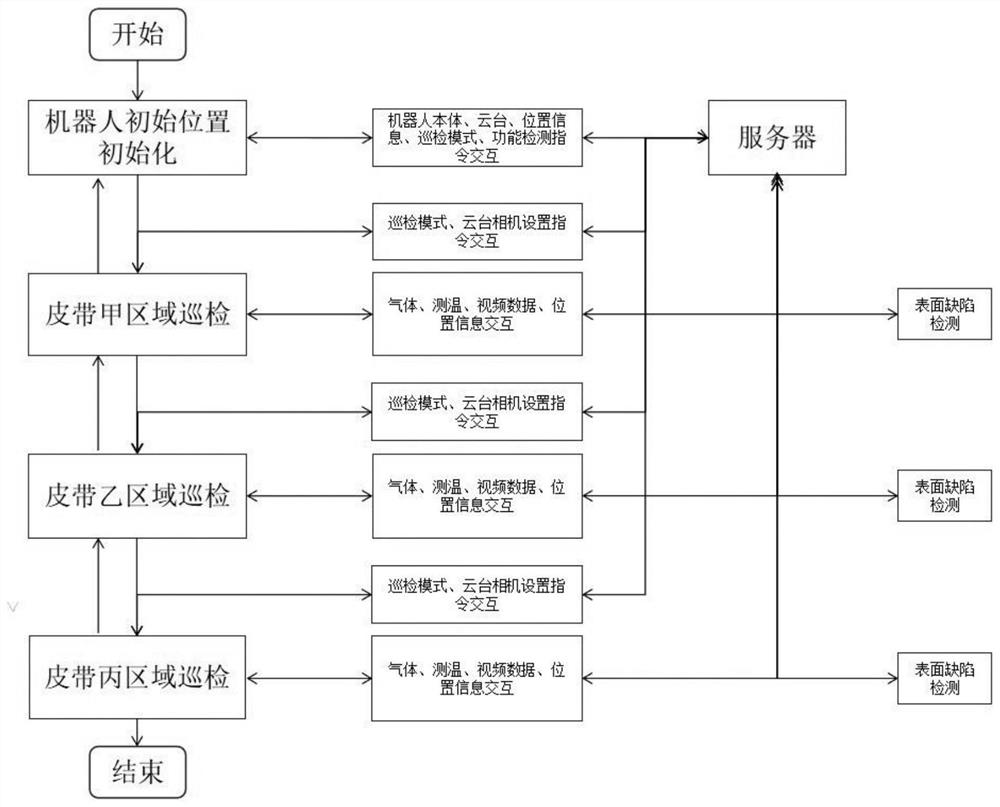

[0046] Such as figure 1 As shown, an intelligent inspection and detection method for coal conveying belt conveyor in the coal conveying bunker area, including a set of single track, a mobile robot, a set of automatic rotating platform, a set of sound sensors, a set of gas detectors and temperature and humidity Sensors, four sets of autonomous charging stations, a set of on-site wireless communication deployment system, background processing server;

[0047] A set of single track: implemented by fixing the top wall or steel frame at a suitable position on the site through the hanger assembly, used to provide the track route of the mobile robot;

[0048] A mobile robot: hooked on the track, providing a sensor carrying platform and an inspection mobile platform, specifically including a chassis module, a safety protection module, a front-end carrying module, a visible light monitoring system, an infrared thermal imager system, and a communication module;

[0049] A set of automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com