Unmanned automatic polishing system

An automatic polishing and robot technology, which is applied in the direction of grinding/polishing equipment, machine tools for surface polishing, grinding feed movement, etc., can solve problems such as noise, dust, and operator damage, and achieve a high degree of automation and improve efficiency , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

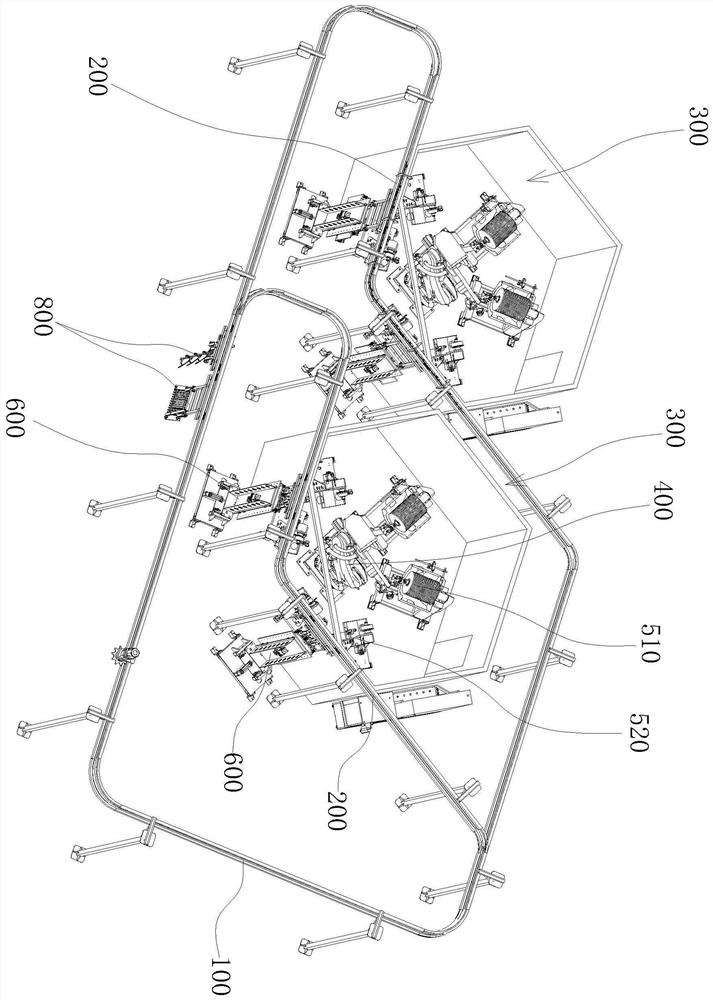

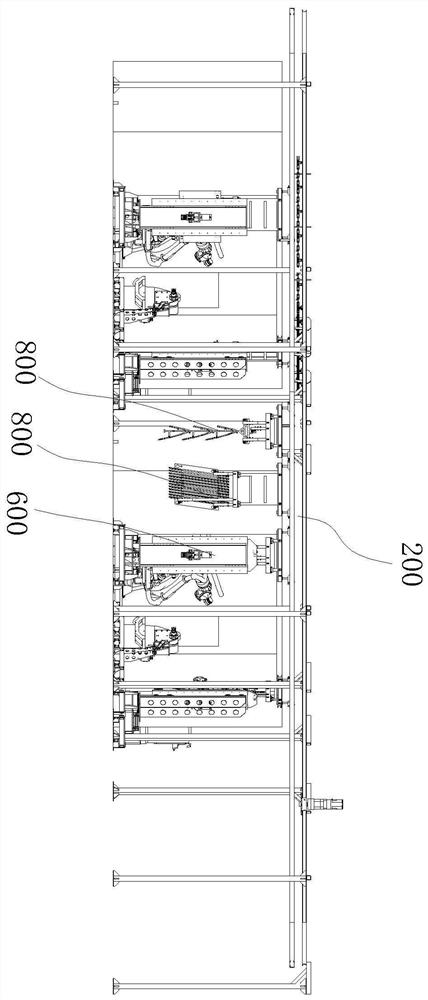

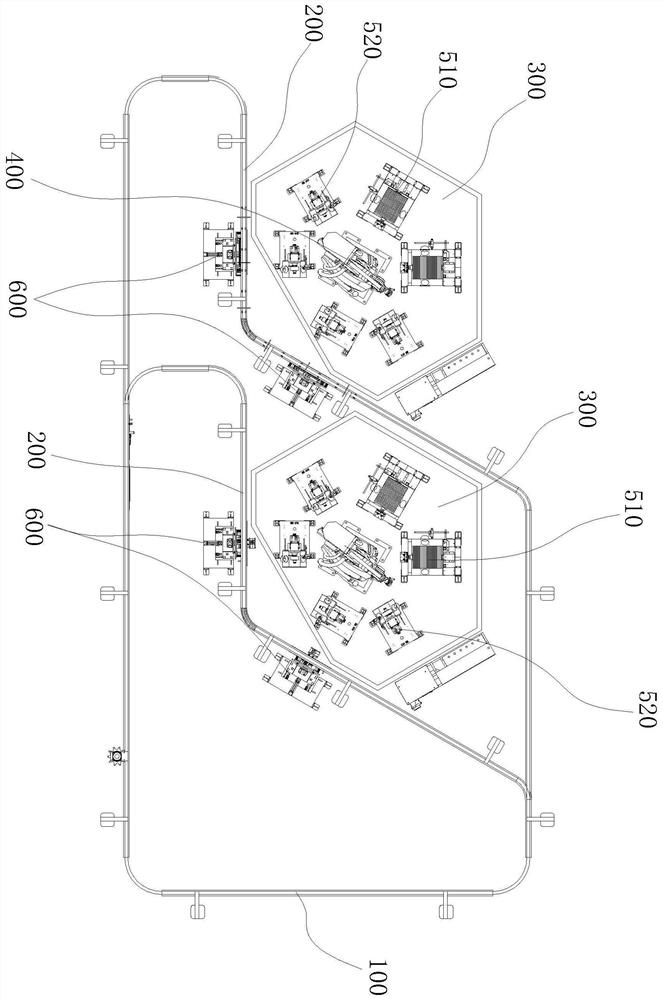

[0036] Such as Figure 1-10 As shown, an unmanned automatic polishing system includes: a logistics chain unit and a polishing unit 300, wherein the logistics chain unit includes a logistics chain main road 100 and at least one logistics chain branch 200, and the logistics chain branch 200 and The main road 100 of the logistics chain is connected; the number of polishing units 300 is at least one, and the polishing unit 300 includes a robot 400, a polishing element and a stand 600 elements, and the robot 400 is provided with a polishing fixture 700, and the logistics chain branch The road 200 is adjacent to the gantry 600 element.

[0037] What needs to be added is that, in an actual structure, the components of the stand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com