Anti-deviation drilling equipment for machining motor shell of electric vehicle

A technology for motor casings and drilling equipment, applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., can solve problems such as large safety hazards, waste of water resources, and inability to clamp motor casings to avoid safety problems The effect of eliminating hidden dangers and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

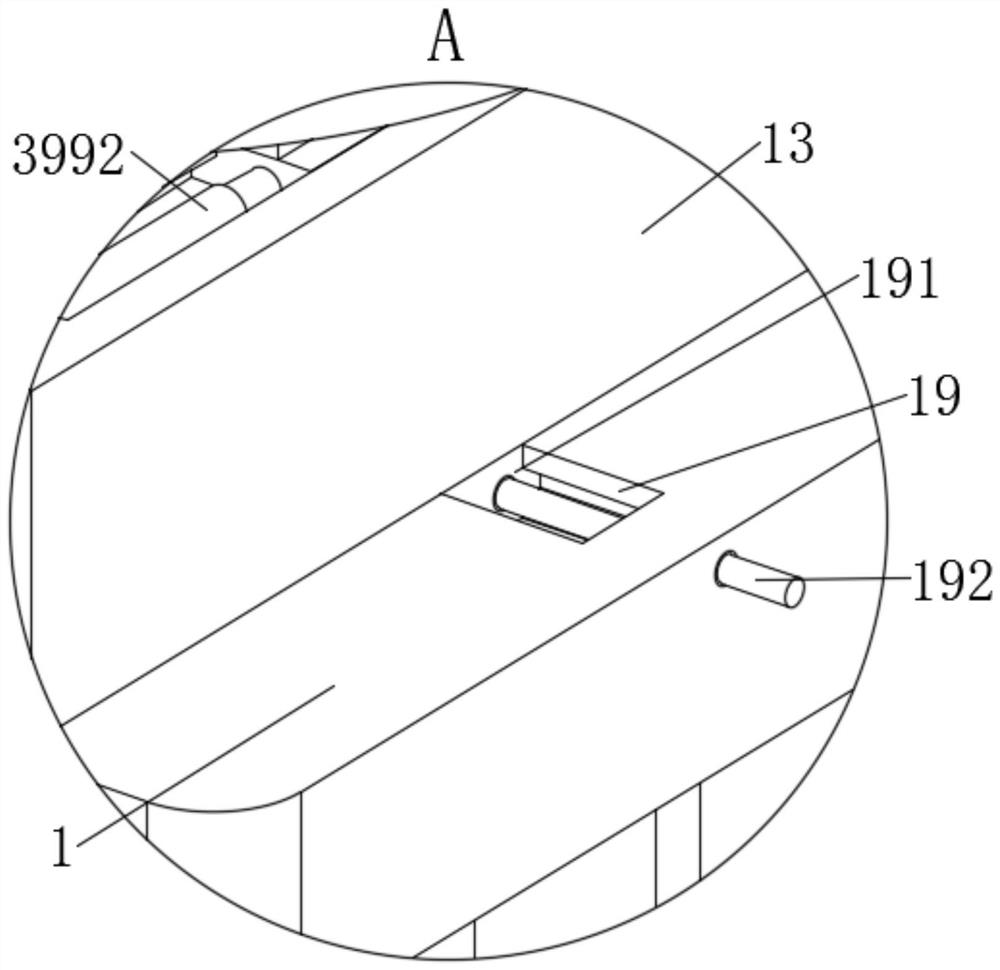

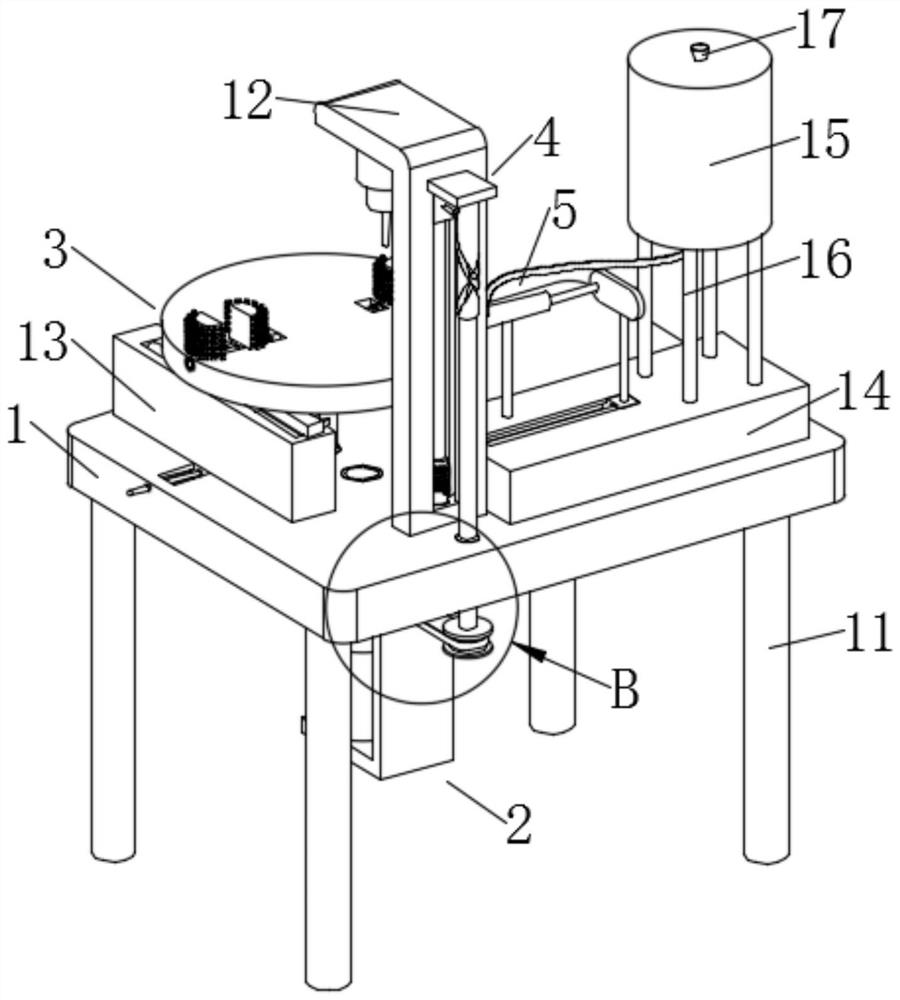

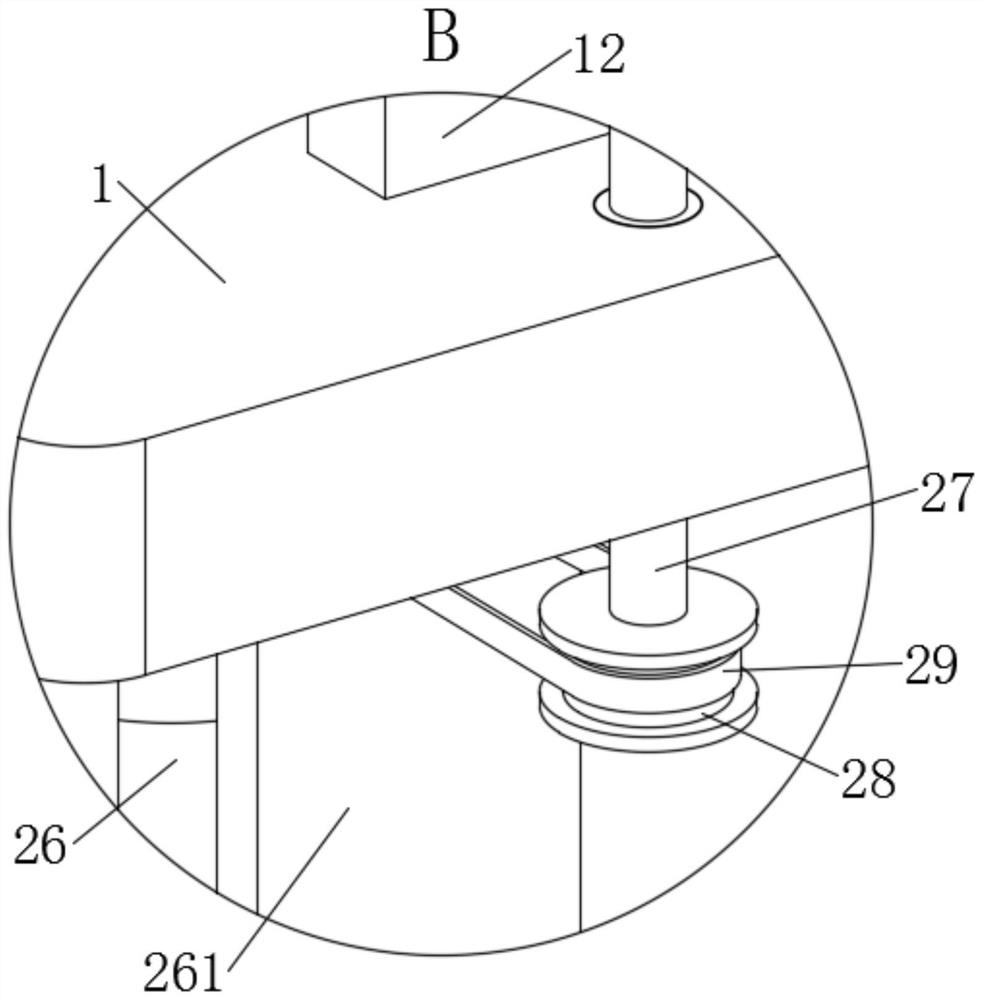

[0038] As an embodiment of the present invention, the lower surface of the drilling platform 1 is evenly distributed and fixedly installed with first supporting legs 11, the first supporting legs 11 can effectively improve the stability of the drilling platform 1, and the bottom end of the water storage bucket 15 Evenly distributed and fixedly connected with a second support leg 16, the second support leg 16 can support and fix the water storage bucket 15, one end of the second support leg 16 is fixedly connected with the upper surface of the second fixing base 14, and the upper surface of the water storage bucket 15 is fixedly installed There is a hopper 17, and the hopper 17 can facilitate the staff to add drilling water to the inside of the water storage bucket 15. The lower surface of the water storage bucket 15 is fixedly connected with a drain hose 18, and the drain hose 18 can be transported into the water storage bucket 15. Drilling water, the drilling platform 1 near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com