Sulfur-tolerant pre-shift catalyst and preparation and vulcanization method thereof

A catalyst and pre-shift technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of less research and reports on sulfur-resistant pre-shift catalyst carriers, and achieve good economic benefits and Environmental benefits, outstanding activity stability, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

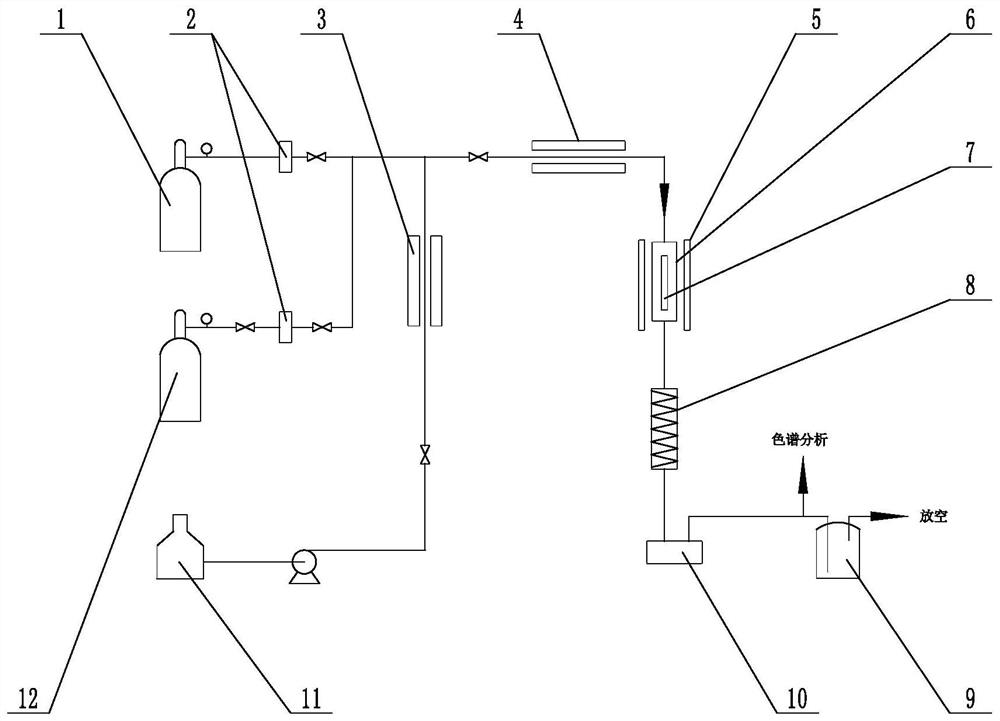

Method used

Image

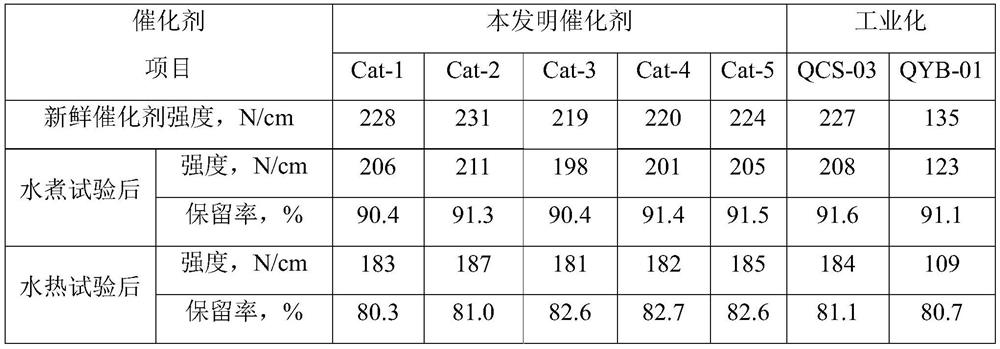

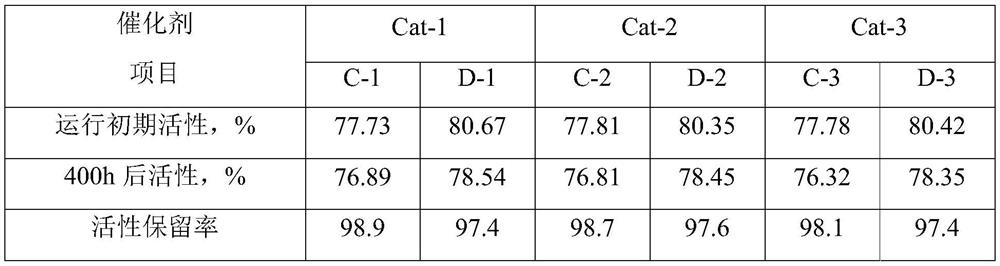

Examples

Embodiment 1

[0041] The preparation method of described sulfur-resistant pre-shift catalyst comprises the steps:

[0042] 1) Dissolve 2.4g of α-titanic acid in 60mL of dilute nitric acid solution to prepare a modified solution; add the modified solution to 120g of sepiolite and knead for 4 hours, after standing for 4 hours, dry at 100°C for 24h, roast at 420°C for 8h and pulverize To obtain modified sepiolite to less than 160 mesh;

[0043] 2) Weigh 8.5g of cobalt nitrate and 18.0g of ammonium molybdate, add 60mL of ammonia water and 3mL of ethylenediamine, heat to 70°C to obtain a clear solution A1, the measured pH value is 12, add 3g of oxalic acid and 2mL of acetic acid respectively Remove 20mL of deionized water to obtain solution B1;

[0044] 3) Crush the waste hydrogenation catalyst to 160 mesh, weigh 100g as aggregate, mix with modified sepiolite and 2.02g of metatitanic acid, add solution A1, knead evenly, then add solution B1, knead evenly, Shaped, air-dried, and then calcined a...

Embodiment 2

[0046] The preparation method of described sulfur-resistant pre-shift catalyst comprises the steps:

[0047] 1) Dissolve 4.53α-titanic acid in 80mL dilute nitric acid solution to prepare a modified solution; add the modified solution to 150g sepiolite and knead for 6 hours, let it stand for 8 hours, dry at 120°C for 16 hours, roast at 450°C for 8 hours and pulverize To obtain modified sepiolite to less than 160 mesh;

[0048] 2) Weigh 15.08g of cobalt nitrate and 49.78g of ammonium molybdate, add 100mL of ammonia water and 4mL of ethylenediamine, heat to 75°C to obtain a clear solution A2, the measured pH value is 12, add 5g of citric acid to 40mL of deionized Obtain solution B2 in water;

[0049] 3) Pulverize the waste hydrogenation catalyst to 160 mesh, weigh 100g as aggregate, mix evenly with modified sepiolite and 2.83g metatitanic acid, add solution A2, knead evenly, then add solution B2, knead evenly, and Molded, air-dried, and then calcined at 460°C for 8 hours to obt...

Embodiment 3

[0051] The preparation method of described sulfur-resistant pre-shift catalyst comprises the steps:

[0052] 1) Dissolve 7.25α-titanic acid in 100mL dilute nitric acid solution to prepare a modified solution; add the modified solution to 140g sepiolite and knead for 6 hours, let stand for 12 hours, dry at 100°C for 24 hours, roast at 420°C for 6 hours and pulverize To obtain modified sepiolite to less than 160 mesh;

[0053] 2) Weigh 20.11g of cobalt nitrate and 68.66g of ammonium molybdate, add 150mL of ammonia water and 6mL of ethylenediamine, heat to 70°C to obtain a clear solution A3, the measured pH value is 11.5, add 6g of oxalic acid and 12mL of acetic acid respectively 30mL deionized water to obtain solution B3;

[0054] 3) Crush the waste hydrogenation catalyst to 160 mesh, weigh 100g as aggregate, mix evenly with modified sepiolite, 6.5g squid powder, and 6.13g metatitanic acid, add solution A3, knead evenly, and then add solution B3, kneaded evenly, shaped, air-dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com