Method for assembling Van der Waals heterojunction photocatalysis and photoelectrocatalysis materials from bottom to top

A photocatalytic material and photoelectric catalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of high cost of separation and recovery, hindering the industrial application of photocatalytic materials, and unfavorable photocatalytic reactions. Equipment design and other issues, to achieve the effect of simple and easy method, excellent photocatalytic and photocatalytic cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A bottom-up assembly method of van der Waals heterojunction photocatalysis and photoelectrocatalysis materials, comprising the following steps:

[0045] 1) Add 0.020 g of zero-dimensional P25 photocatalytic material to 10 mmol / L tris(hydroxymethyl)aminomethane aqueous solution, and disperse it by ultrasonic wave for 60 minutes to obtain suspension solution A;

[0046] 2) Under stirring, add 0.010 g of dopamine to the solution A. The dopamine undergoes dopamine polymerization reaction on the surface of the powder photocatalytic material. The dopamine polymerization reaction time is 5 h, and the dopamine forms a uniform polydopamine coating on the surface of the photocatalytic material;

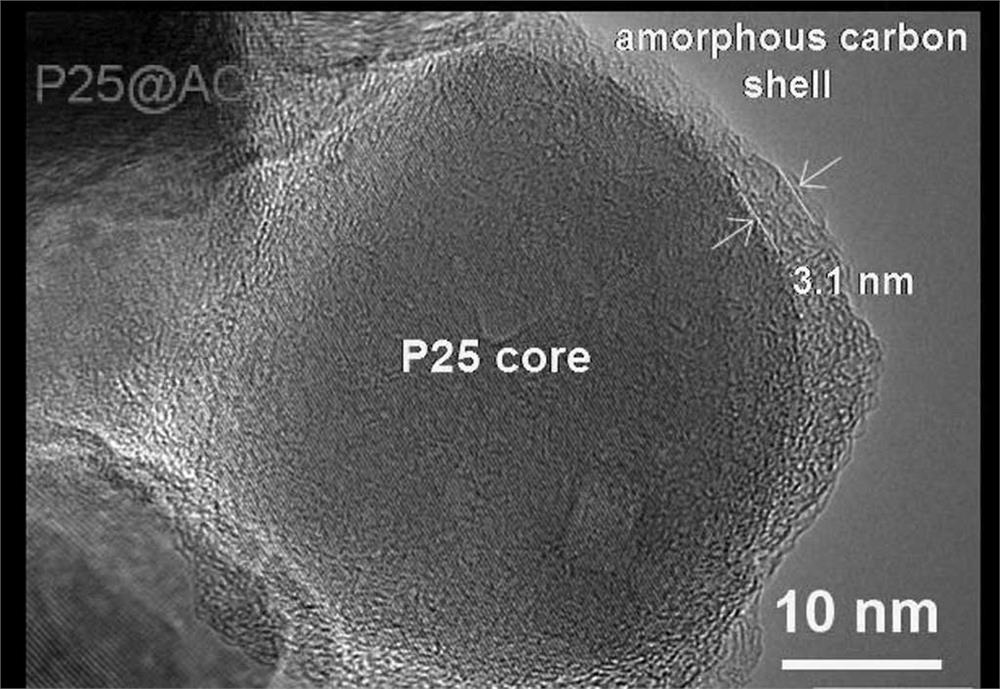

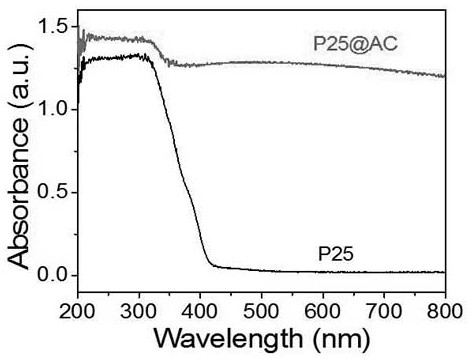

[0047] 3) The dopamine polymerization product was separated by centrifugation, washed three times with deionized water, dried at 90 °C for 10 h, kept under argon atmosphere, and roasted at 400 °C for 12 h. During the roasting process, the argon flow rate was 50 SCCM. The layer is carboni...

Embodiment 2

[0051] A bottom-up assembly method of van der Waals heterojunction photocatalysis and photoelectrocatalysis materials, comprising the following steps:

[0052] 1) Add 0.020 g of one-dimensional TiO 2 Add fibers to 10 mmol / L tris(hydroxymethyl)aminomethane aqueous solution, and ultrasonically disperse for 60 minutes to obtain suspension solution A;

[0053] 2) With stirring, add 0.010 g dopamine to solution A, dopamine in powdered TiO 2 The dopamine polymerization reaction was carried out on the surface of the fiber, and the dopamine polymerization reaction time was 5 h. 2 A uniform polydopamine coating is formed on the fiber surface;

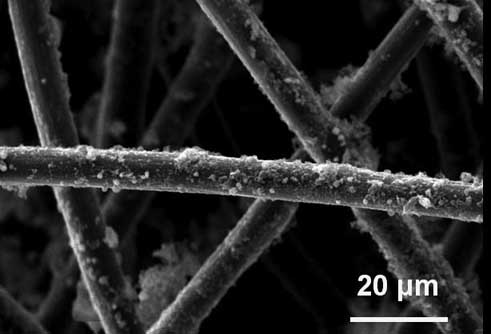

[0054] 3) The dopamine polymerization product was separated by centrifugation, washed three times with deionized water, dried at 90 °C for 10 h, kept under argon atmosphere, and calcined at 400 °C for 12 h. During the roasting process, the argon flow rate was 50 SCCM, TiO 2 The polydopamine coating on the fiber surface is carbonized into a ca...

Embodiment 3

[0058] A bottom-up assembly method of van der Waals heterojunction photocatalysis and photoelectrocatalysis materials, comprising the following steps:

[0059] 1) Dilute 0.020 g of two-dimensional g-C 3 N 4 Nanosheets were added to 10 mmol / L tris(hydroxymethyl)aminomethane aqueous solution, and ultrasonically dispersed for 60 minutes to obtain suspension solution A;

[0060] 2) With stirring, add 0.010 g dopamine to solution A, dopamine in g-C 3 N 4 The dopamine polymerization reaction was carried out on the surface of the nanosheets, the dopamine polymerization reaction time was 5 h, and the dopamine 3 N 4 A uniform polydopamine coating is formed on the surface of the nanosheets;

[0061] 3) The dopamine polymerization product was separated by centrifugation, washed three times with deionized water, dried at 90 °C for 10 h, kept under argon atmosphere, and calcined at 400 °C for 12 h. During the roasting process, the argon flow rate was 50 SCCM, g-C 3 N 4 Carbonization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com