Lower feeding hydrogenation reactor and liquid phase hydrogenation method

A hydrogenation reactor and hydrogenation reaction technology, which is applied in the field of oil refining and chemical industry, can solve the problems of large floor area, high production cost, and high energy consumption, and achieve the effects of low equipment investment, reduction of liquid entrainment in the gas phase, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

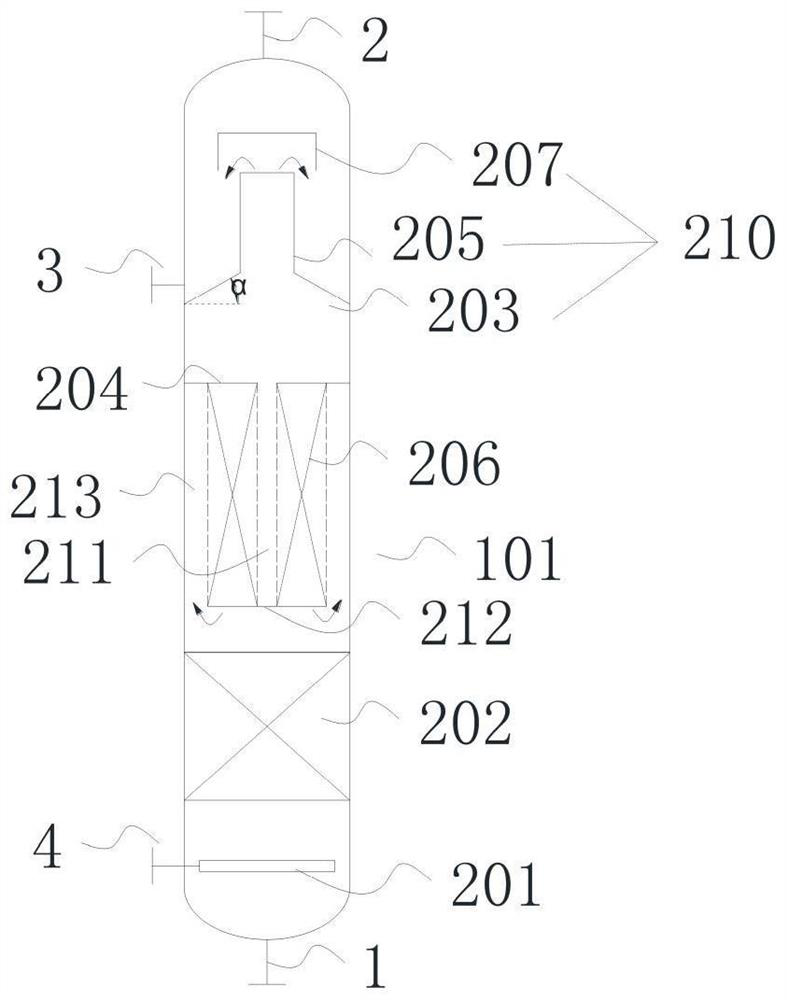

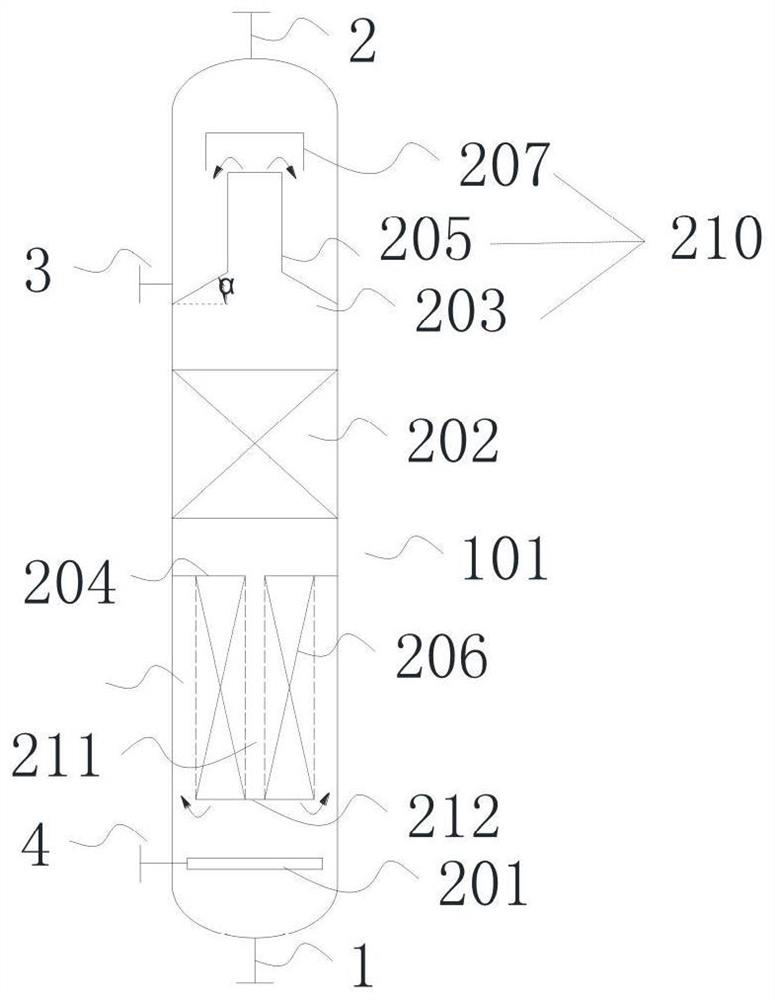

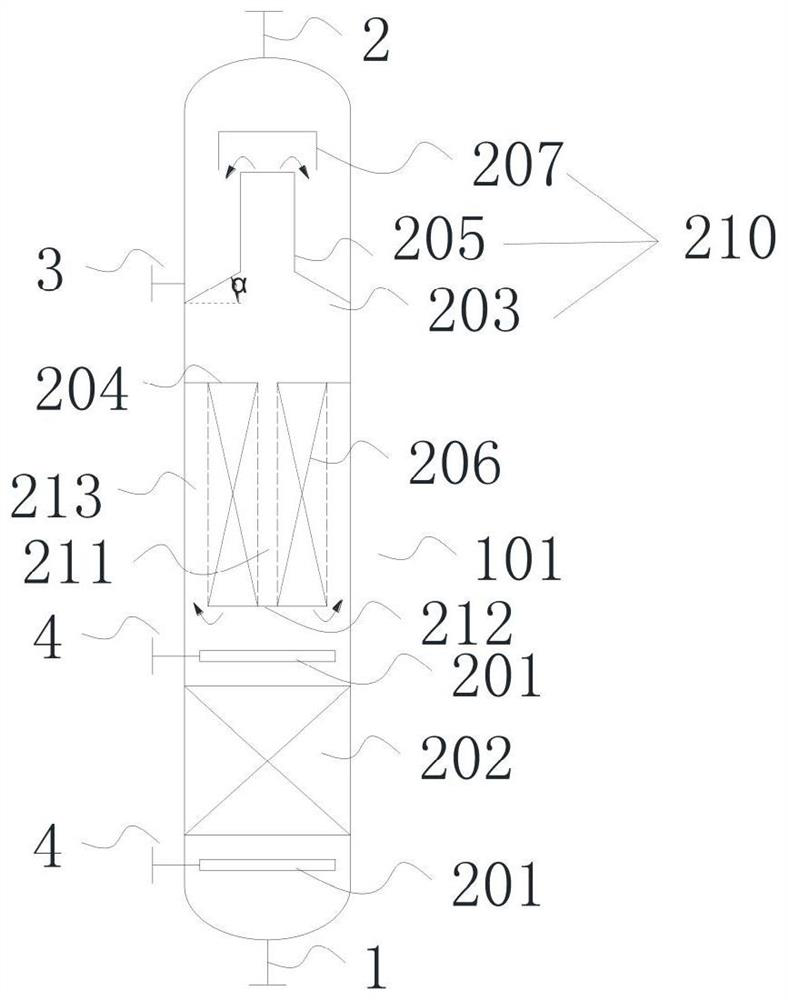

[0068] Such as figure 1 , Figure 11 As shown, a lower feed hydrogenation reactor, the lower feed hydrogenation reactor includes a shell 101, the bottom of the shell 101 is provided with a feed pipeline 1, the top is provided with a gas phase outlet pipeline 2, and the upper part is provided with a liquid Phase outlet pipeline 3;

[0069] The housing 101 is provided with a hydrogenation reaction zone and a gas-liquid phase separation zone. The hydrogenation reaction zone includes an axial reaction zone and a radial reaction zone. The axial reaction zone consists of an axial catalyst bed 202 The radial reaction zone is composed of a radial catalyst bed 206, the axial catalyst bed 202 is arranged below the radial catalyst bed 206, and the axial catalyst bed 202 is provided with a gas distributor 201 , the gas distributor 201 is connected with a hydrogen gas inlet pipeline 4, the gas-liquid phase separation zone is located above the hydrogenation reaction zone, and a gas-liquid...

Embodiment 2

[0083] The difference with embodiment 1 is: the mol ratio of hydrogen and naphtha is 0.038: 1, and the liquid hourly space velocity of naphtha is 4.2h -1 , the reaction temperature of naphtha hydrogenation reaction is 205°C, and the reaction pressure is 2.05MPaG.

[0084] After testing, the content of sulfur and nitrogen in the hydrogenation product is less than 0.3ppm, the content of arsenic is less than 0.8ppb, the content of lead is less than 6.5ppb, and the bed pressure drop is 15kPa.

Embodiment 3

[0086] The difference with embodiment 1 is: the mol ratio of hydrogen and naphtha is 0.03: 1, and the liquid hourly space velocity of naphtha is 5h -1 , the reaction temperature of naphtha hydrogenation reaction is 198°C, and the reaction pressure is 2.1MPaG.

[0087] After testing, the content of sulfur and nitrogen in the hydrogenation product is less than 0.35ppm, the content of arsenic is less than 0.9ppb, the content of lead is less than 8ppb, and the bed pressure drop is 17kPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com