Electronic atomized liquid containing borneol plant component and preparation method thereof

A technology of electronic atomization and plant ingredients, which is applied in the direction of medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, active ingredients of hydroxyl compounds, etc. Consumers have problems such as satisfaction and pleasure, and achieve the effects of reducing the risk of cardiovascular disease, improving the utilization rate of raw materials, and lasting aromatic and refreshing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

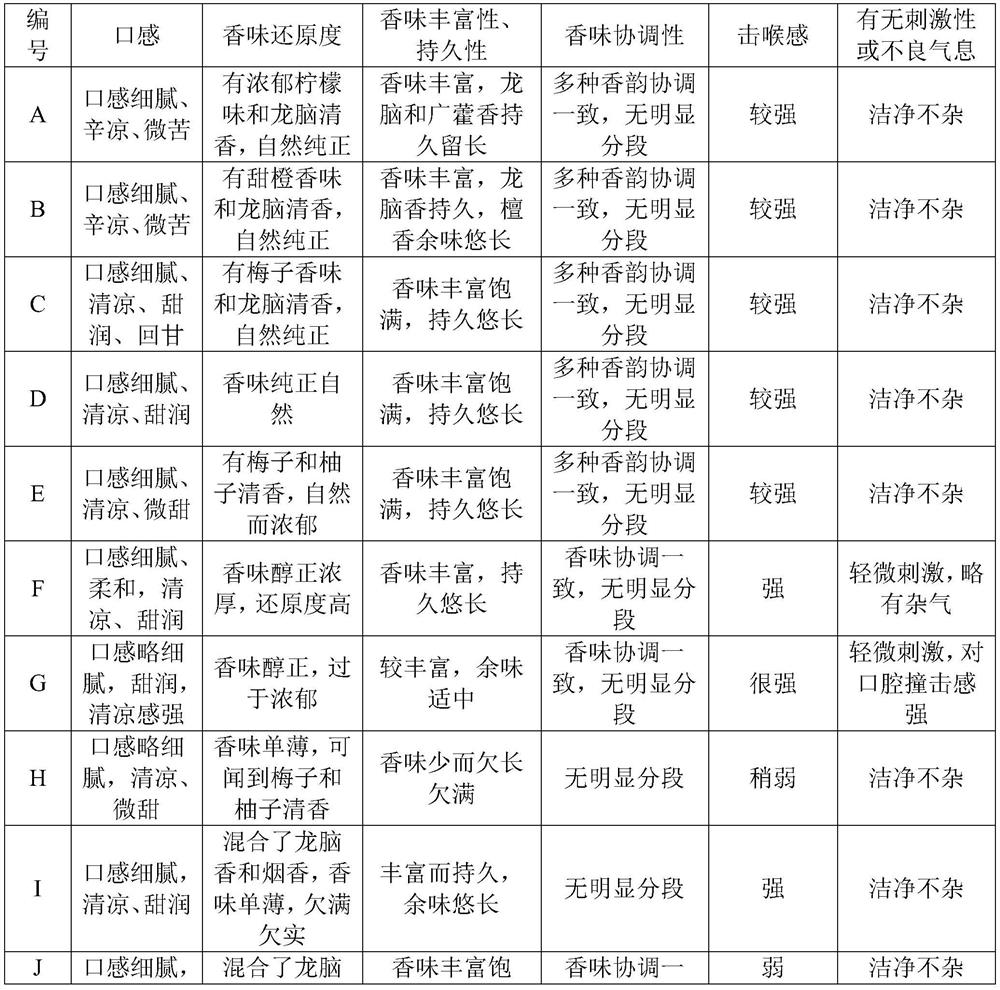

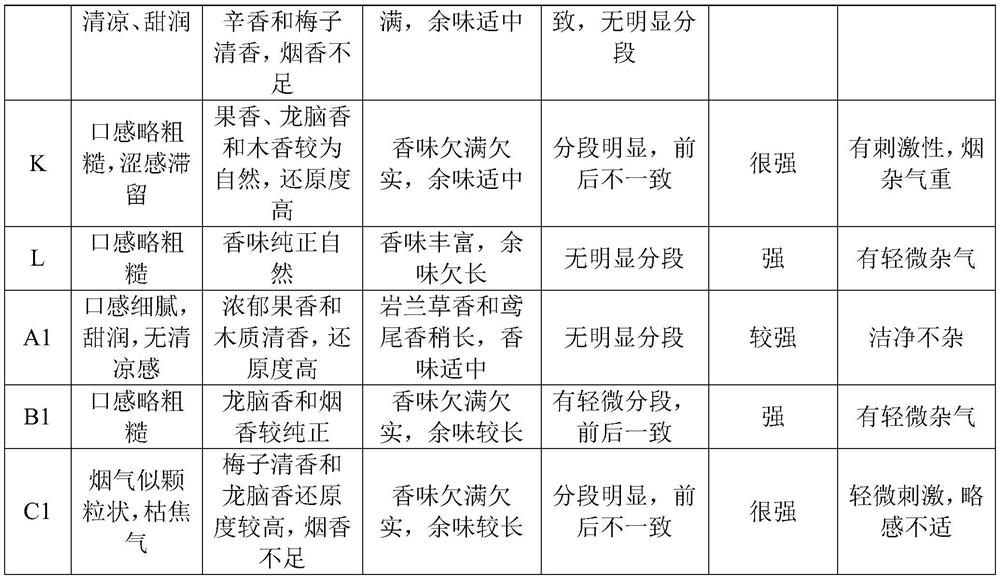

Examples

Embodiment 1

[0044] (1) Weigh 100 g of crushed waste tobacco stems and tobacco leaf materials, add 500 mL of NaOH solution with a mass fraction of 4%, start stirring, heat up to 75 ° C, keep warm for 3 h, filter to obtain tobacco filter cake, and use pure water Wash until neutral; weigh 0.2g of aroma-producing active dry yeast, put the dry yeast into 20 times the amount of 2.5% sucrose water, and activate it at 33-35°C for 10 hours; then mash the tobacco filter cake and put it into the fermenter , add 500mL of purified water, stir to fully submerge, add the above-mentioned activated aroma yeast, set the temperature at 25°C, ferment for 15 days, squeeze and filter to obtain 491g of tobacco fragrance fermentation liquid; carry out molecular distillation of tobacco fragrance fermentation liquid, Set distillation temperature T=70°C, feed temperature 60°C, rotation speed 300r / min, adjust feed flow in real time to prevent bumping, and collect 255g of cigarette aroma light components in the distil...

Embodiment 2

[0048] (1) Weigh 100 g of crushed waste tobacco stems and tobacco leaf materials, add 500 mL of NaOH solution with a mass fraction of 4%, start stirring, heat up to 75 ° C, keep warm for 3 h, filter to obtain tobacco filter cake, and use pure water Wash until neutral; weigh 0.2g of aroma-producing active dry yeast, put the dry yeast into 20 times the amount of 2.5% sucrose water, and activate it at 33-35°C for 10 hours; then mash the tobacco filter cake and put it into the fermenter , add 500mL of purified water, stir to fully submerge, then add the above-mentioned activated aroma yeast, set the temperature at 25°C, ferment for 15 days, squeeze and filter to obtain 494g of tobacco fragrance fermentation liquid; carry out molecular distillation of tobacco fragrance fermentation liquid, Set distillation temperature T=80°C, feed temperature 70°C, rotation speed 300r / min, adjust feed flow in real time to prevent bumping, and collect 263g of cigarette aroma light components in the d...

Embodiment 3

[0052] (1) Weigh 100 g of crushed waste tobacco stems and tobacco leaf materials, add 500 mL of NaOH solution with a mass fraction of 4%, start stirring, heat up to 75 ° C, keep warm for 3 h, filter to obtain tobacco filter cake, and use pure water Wash until neutral; weigh 0.2g of aroma-producing active dry yeast, put the dry yeast into 20 times the amount of 2.5% sucrose water, and activate it at 33-35°C for 10 hours; then mash the tobacco filter cake and put it into the fermenter , add 500mL of purified water, stir to fully submerge, then add the above-mentioned activated aroma yeast, set the temperature at 25°C, ferment for 15 days, squeeze and filter to obtain 497g of tobacco fragrance fermentation liquid; carry out molecular distillation of tobacco fragrance fermentation liquid, Set distillation temperature T=100°C, feed temperature 90°C, rotation speed 300r / min, adjust feed flow in real time to prevent bumping, and collect 295g of cigarette aroma light components in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com