Control method of automatic lifting device for auxiliary disassembly and assembly of mutual inductor in box transformer substation

An automatic lifting and device control technology, applied in the direction of lifting devices, user/computer interaction input/output, neural learning methods, etc., can solve problems that cannot fully meet the lifting environment, cannot realize automatic and precise control of lifting devices, and achieve recognition The effect of high degree, strong applicability and easy system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

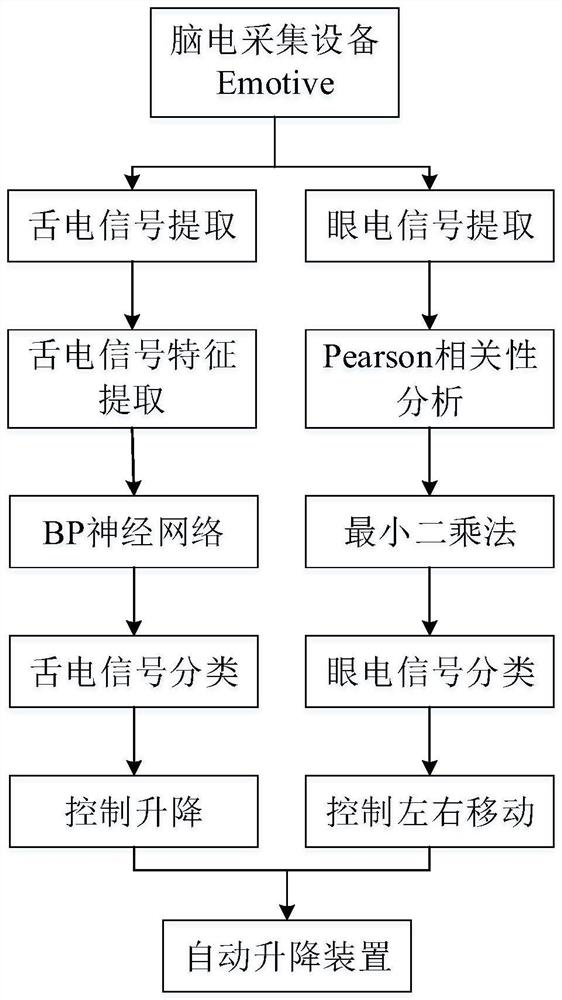

[0030] refer to figure 1 , a specific embodiment of an automatic lifting device control method for auxiliary disassembly and assembly of transformers in a box-type transformer, including tongue electrical signal control and eye electrical signal control. Tongue electric signal control specifically includes the following steps:

[0031] Step 1. Use the EEG acquisition device Emotive to collect EEG signals;

[0032] Step 2. Select the EEG signals of leads AF3 and AF4 as the identification object of the tongue electric signal;

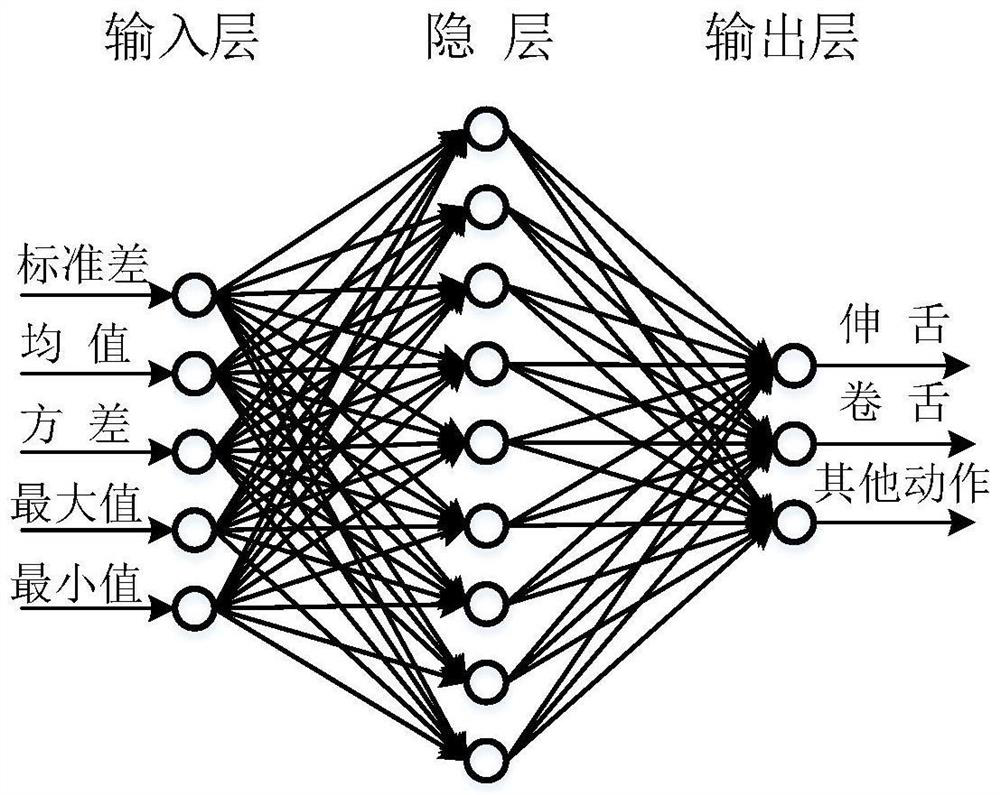

[0033] Step 3. Use the moving rectangular window with a step size of 100 sampling points to move on the selected lead EEG signal, and calculate the five characteristics of the EEG signal's maximum value, minimum value, mean value, standard deviation and variance in the moving rectangular window .

[0034] Step 4.1, according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com