Heavy-load servo omni-directional driving device based on active damping and AGV

A driving device and active shock absorption technology, which is applied in the direction of power device, electric power device, control device, etc., can solve the problems such as the increase of the diameter and width of the universal wheel, which cannot meet the requirements of AGV product dimensions, high maintenance cost, and vibration , to meet the needs of automatic handling of objects, reduce capital investment, and facilitate personnel maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

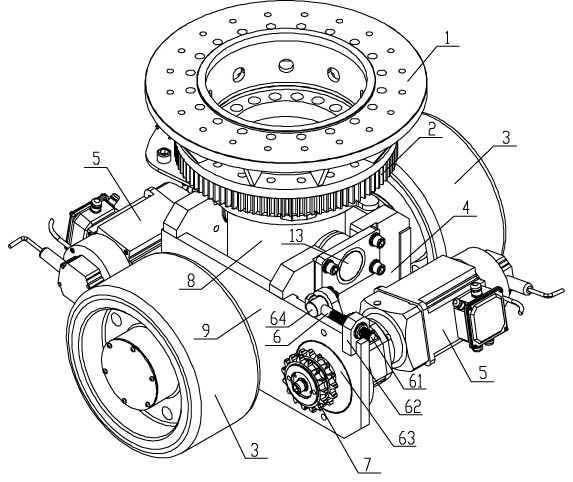

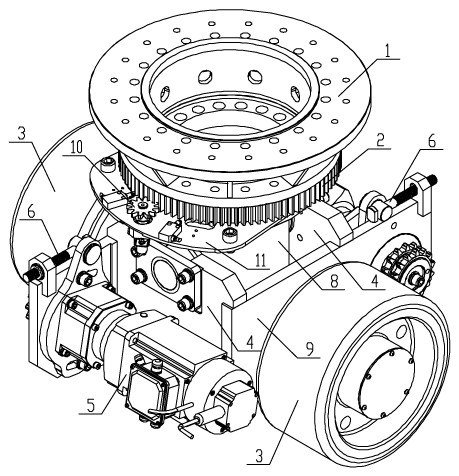

[0025] see Figure 1-7 , this embodiment is a heavy-duty servo omnidirectional drive device based on active shock absorption, including a mounting frame, the mounting frame is composed of four support plates, the four support plates are perpendicular to each other, and a rectangular installation cavity is formed in the middle, and two of them One opposite support plate is the wheel mounting plate 9, and the other two relative support plates are the lifting mechanism mounting plate 4, each of the two wheel mounting plates 9 is equipped with a driving wheel shaft through a bearing, and a driven sprocket 14 is housed on the driving wheel shaft. , the outer end of the driving wheel shaft is equipped with a driving wheel 3, and the two driving wheels 3 are arranged symmetrically. Control, the output end of driving motor 5 is equipped with driving sprocket 7, and driving sprocket 7 is connected with driven sprocket 14 by transmission chain; An elevating mechanism 8 is housed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com