Assembly type base plate for powder bed melting additive manufacturing and using method thereof

An additive manufacturing and assembly technology, applied in the field of fabricated substrates for powder bed melting additive manufacturing, can solve the problems of small additive manufacturing samples, difficult processing of special-shaped grooves and special-shaped sliders, etc. The effect of reducing manufacturing costs and reducing assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

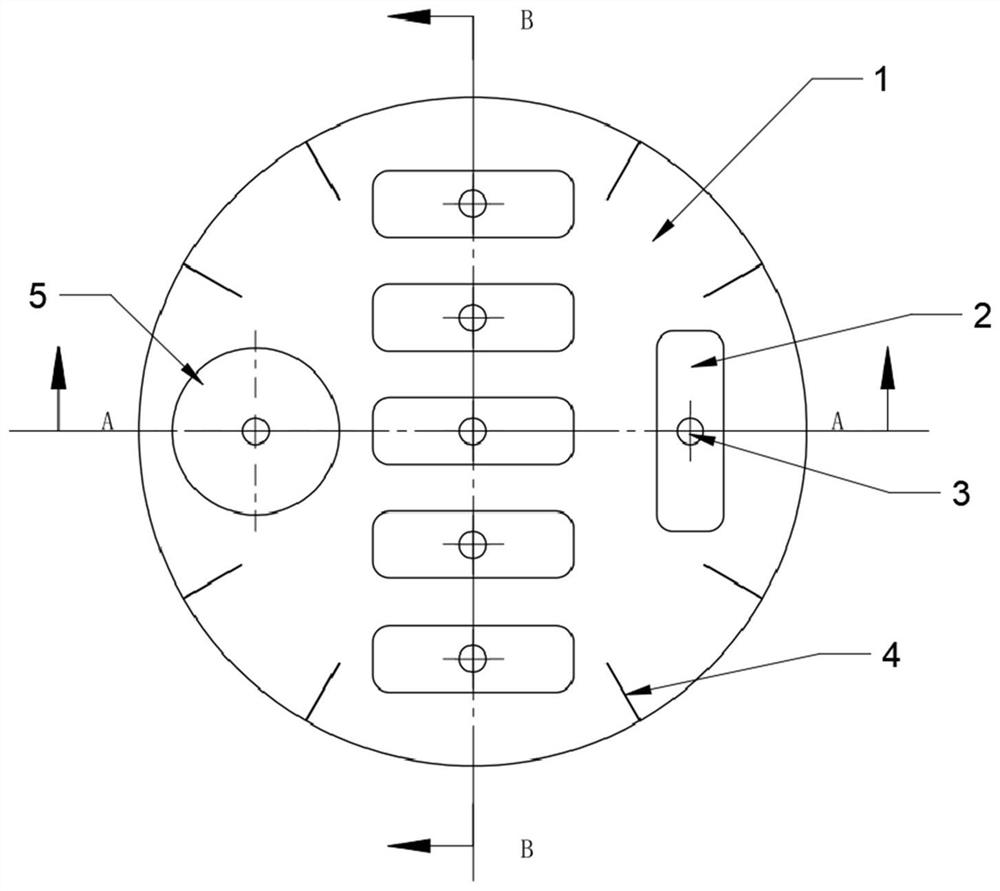

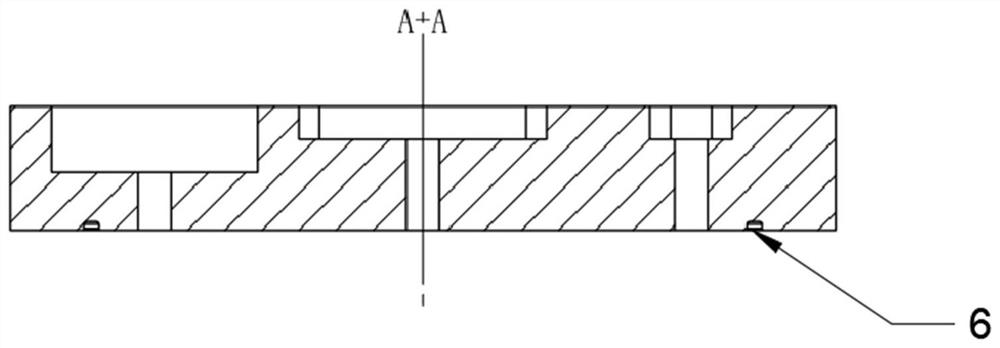

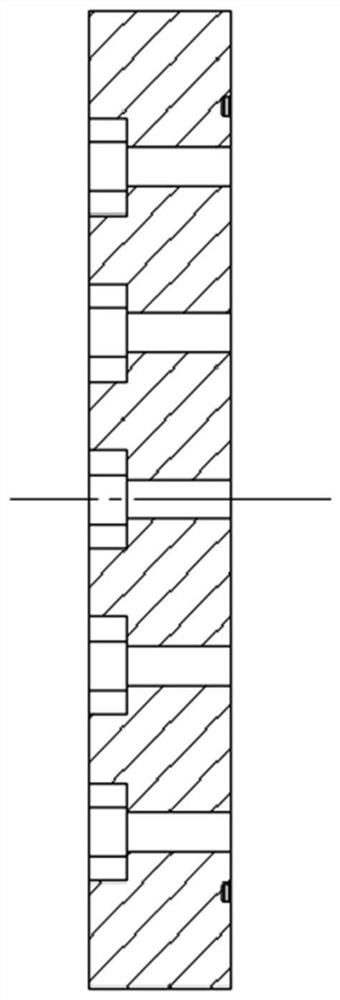

[0041] This embodiment provides an assembled substrate for powder bed melting additive manufacturing and a method for using the same. Such as figure 1 As shown, the assembled substrate includes a standard substrate 1 , a rounded rectangular groove 2 , a through hole 3 - 1 in the assembly groove, a scoring line 4 and a circular groove 5 . The standard substrate 1 is provided with six rounded rectangular slots 2 for accommodating small rounded rectangular substrates, and a circular slot 5 for accommodating a small circular substrate 7, and a through hole 3- 1. Wherein, the cross-section A-A of the standard substrate 1, such as figure 2 shown. Cross-section B-B of standard substrate 1, such as image 3 shown. The bottom of the standard substrate 1 is provided with a sealing ring groove 6 . The rounded rectangular small substrate 7 in this embodiment, such as Image 6 shown.

[0042] The basic style of the standard substrate 1 refers to the standard substrate drawing of t...

Embodiment 2

[0046] The assembled substrate for powder bed melting additive manufacturing provided in this embodiment, such as Figure 4-5 As shown, the same as embodiment 1, the difference is that the through holes are changed into bolt holes. The basic style of the standard substrate 1 refers to the standard substrate drawing of the EOS M100 model printer, with a diameter of 100mm and a sealing ring groove 6 for positioning and fixing at the bottom. The depth of the rounded rectangular groove 2 is 4mm, and its shape is a rectangular chamfer of 30mm×10mm with 2.5mm. The depth of the circular groove is 8 mm and its shape is a circle with a diameter of 25 mm. The center position of each groove opens the bolt hole of M6 or M8.

[0047] The method for reusing the assembled substrate for powder bed melting additive manufacturing provided in this embodiment includes: first placing the standard substrate 1 on a flat and firm working platform. Align the small substrate 7 with the notch and pla...

Embodiment 3

[0050] Using the fabricated substrate for powder bed melting additive manufacturing and the method of use in Embodiment 2, the difference is: firstly, the standard substrate 1 is placed on a flat and firm working platform. The small substrate 7 is cooled and shrunk in liquid nitrogen, then taken out with clamps, quickly put into the assembly groove 2, and the interference fit can be realized after the small substrate 7 is heated to room temperature. Take a deflection meter to detect whether the assembly accuracy of the small substrate 7 and the standard substrate 1 meets the requirements. After all the assembly slots 2 of the standard substrate 1 are filled, the standard substrate 1 is positioned on the printing platform of the printer according to the sealing ring groove 6 . Finally, the printing position of the substrate is adjusted according to the positioning line 4 on the standard substrate to ensure that the actual printing position coincides with the printing area set b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com