MOS type power device

A technology of power devices and ceramics, applied in the field of MOS type power devices, can solve the problems of high working temperature of field effect transistors, poor heat dissipation effect, softening of solder joints, etc., and achieve the effect of facilitating heat diffusion, reducing volume and reducing thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

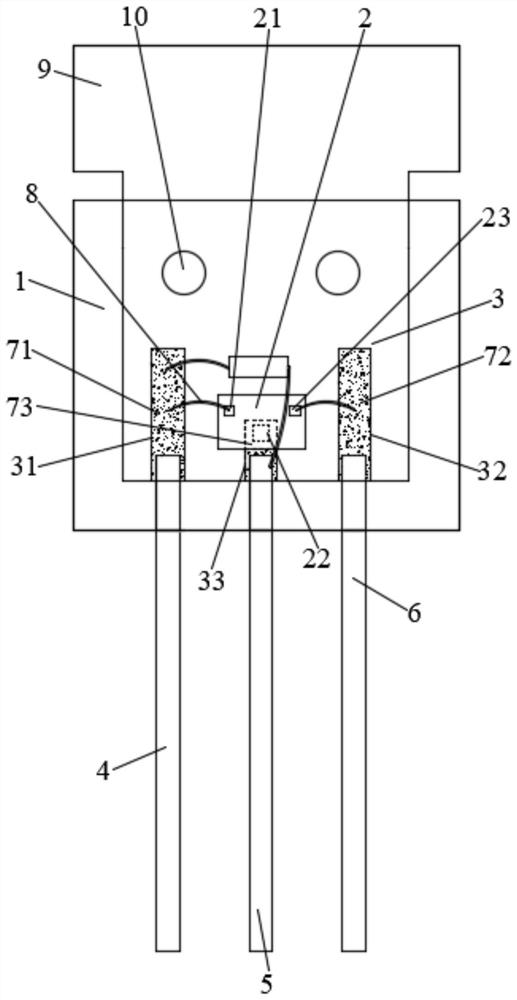

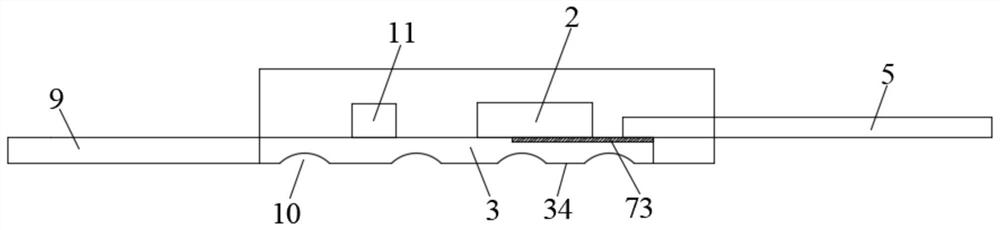

[0026] Embodiment 1: A MOS type power device, including: a MOSFET chip 2 located in an epoxy package 1, a fast recovery diode 11, a ceramic heat conducting body 3, a source pin 4, a drain pin 5 and a gate tube Pin 6, the source pin 4, the drain pin 5 and the gate pin 6 extend outward from the epoxy package 1;

[0027] One surface of the ceramic heat conducting body 3 is provided with a first strip-shaped groove 31, a second strip-shaped groove 32 and a third groove 33, and the first strip-shaped groove 31, the second strip-shaped groove 32 and the first strip-shaped groove 32 The three grooves 33 are respectively filled with a first conductive strip 71, a second conductive strip 72 and a conductive block 73;

[0028] The MOSFET chip 2 has a source region 21, a drain region 22 and a gate region 23, and the MOSFET chip 2 is mounted on a ceramic heat-conducting body, and the source region 21, the drain region 22 and the gate region 23 are respectively Electrically connected with...

Embodiment 2

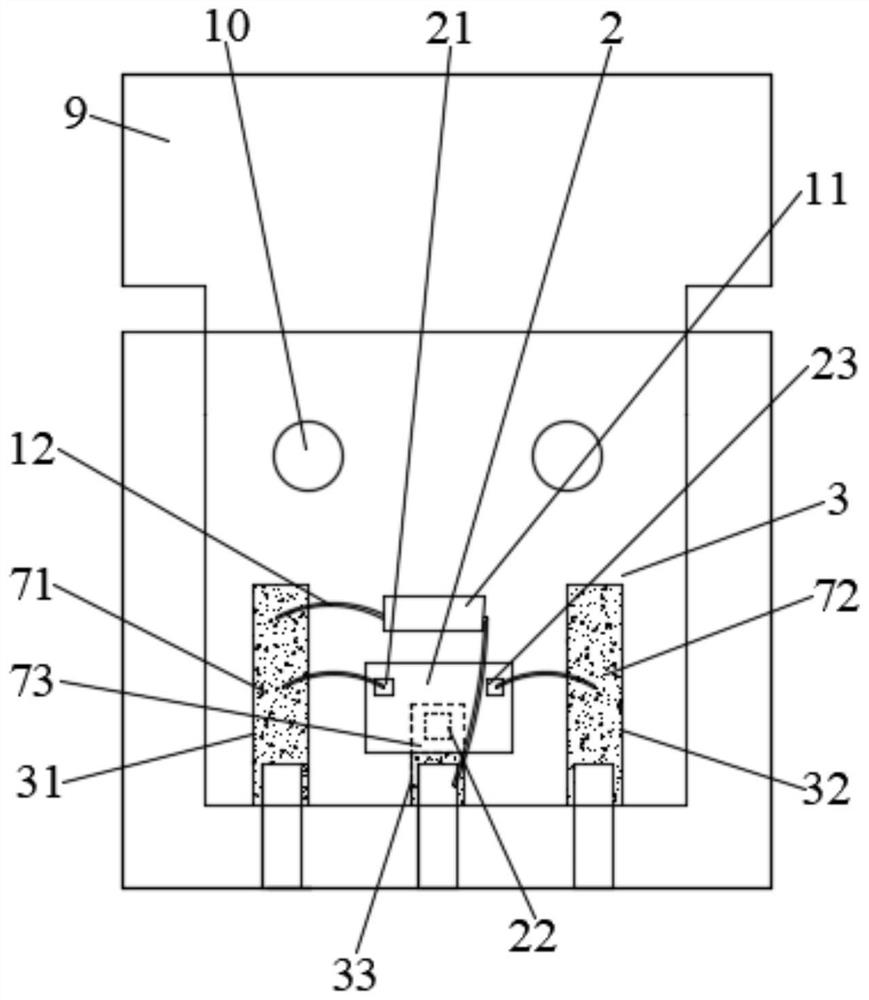

[0035] Embodiment 2: A MOS type power device, including: a MOSFET chip 2 located in an epoxy package 1, a fast recovery diode 11, a ceramic heat-conducting body 3, a source pin 4, a drain pin 5 and a gate tube Pin 6, the source pin 4, the drain pin 5 and the gate pin 6 extend outward from the epoxy package 1;

[0036] One surface of the ceramic heat conducting body 3 is provided with a first strip-shaped groove 31, a second strip-shaped groove 32 and a third groove 33, and the first strip-shaped groove 31, the second strip-shaped groove 32 and the first strip-shaped groove 32 The three grooves 33 are respectively filled with a first conductive strip 71, a second conductive strip 72 and a conductive block 73;

[0037]The MOSFET chip 2 has a source region 21, a drain region 22 and a gate region 23, and the MOSFET chip 2 is mounted on a ceramic heat-conducting body, and the source region 21, the drain region 22 and the gate region 23 are respectively Electrically connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com