Preparation method of photo-cured 3D printing bio-compatible silk fibroin hydrogel

A 3D printing and silk fibroin technology, applied in the direction of additive processing, etc., can solve the problems of low preparation speed and low precision, and achieve the effects of adjustable degradability, good biocompatibility, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

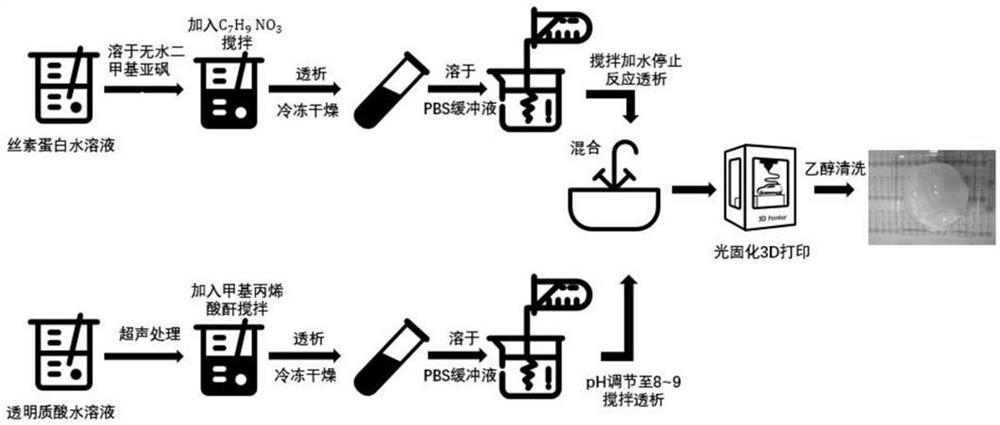

[0045] A preparation method of photocuring 3D printing biocompatible silk fibroin hydrogel provided in this embodiment comprises the following steps:

[0046] S1. Preparation of printing materials;

[0047] S11, preparation of silk fibroin (SF): silkworm cocoons were boiled in mass concentration of 0.3% w / v sodium oleate and 0.2% w / v sodium carbonate solution for 1 hour to remove sericin, then washed and dried at 80 Dissolve 10g of degummed cocoons in 50ml of 9.3mol / l lithium bromide solution at ℃ for 30 minutes to obtain SF solution, then add 10ml of 0.6mol / l sodium oxide solution directly to the SF solution and hydrolyze at 80℃ for 12h, then use acetic acid Cellulose dialysis tubing was dialyzed against deionized water for 3 days. After dialysis, the SF solution was centrifuged at 15,000 g for 20 minutes to remove insoluble aggregates, and then lyophilized;

[0048] S12, preparation of hyaluronic acid-methacrylate (HAMA): dissolve hyaluronic acid (HA) in deionized water to ...

Embodiment 2

[0053] A preparation method of photocuring 3D printing biocompatible silk fibroin hydrogel provided in this embodiment comprises the following steps:

[0054] S1. Preparation of printing materials;

[0055] S11. Preparation of silk fibroin (SF): Silkworm cocoons were boiled in 0.3% w / v sodium oleate and 0.2% w / v sodium carbonate solution for 1 hour to remove sericin, then washed and dried. 10 g of degummed cocoons were dissolved in 50 ml of 9.3 mol / l lithium bromide solution at 80° C. for 30 minutes. Subsequently, 10 ml of a 0.6 mol / l sodium oxide solution were directly added to the SF solution. Hydrolysis was carried out at 80° C. for 12 h, followed by dialysis against deionized water for 3 days using cellulose acetate dialysis tubing. After dialysis, the SF solution was centrifuged at 15,000g for 20 minutes to remove insoluble aggregates and then lyophilized;

[0056] S12. Preparation of hyaluronic acid-methacrylate (HAMA): Hyaluronic acid (HA) was dissolved in deionized ...

Embodiment 3

[0061] A preparation method of photocuring 3D printing biocompatible silk fibroin hydrogel provided in this embodiment comprises the following steps:

[0062] S1. Preparation of printing materials;

[0063] S11. Preparation of silk fibroin (SF): Silkworm cocoons were boiled in 0.3% w / v sodium oleate and 0.2% w / v sodium carbonate solution for 1 hour to remove sericin, then washed and dried. 10 g of degummed cocoons were dissolved in 50 ml of 9.3 mol / l lithium bromide solution at 80° C. for 30 minutes. Subsequently, 10 ml of a 0.6 mol / l sodium oxide solution were directly added to the SF solution. Hydrolysis was carried out at 80° C. for 12 h, followed by dialysis against deionized water for 3 days using cellulose acetate dialysis tubing. After dialysis, the SF solution was centrifuged at 15,000g for 20 minutes to remove insoluble aggregates and then lyophilized;

[0064] S12. Preparation of hyaluronic acid-methacrylate (HAMA): Hyaluronic acid (HA) was dissolved in deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com