Thin-layer low-defect micro-nano graphene and preparation method thereof

A graphene, micro-nano technology, applied in the field of graphene, can solve the problems of difficult industrial production and application, high cost, high defects, etc., and achieve the effect of being suitable for industrial promotion and application, simple method and low defect degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] In principle, the present invention has no special restrictions on the preparation route of the graphene, and those skilled in the art can select and adjust according to actual production conditions, product requirements and quality requirements. The present invention further improves the thinness of graphene and reduces surface functional groups. and degree of defect, ensuring its specific structure, and finally improving the quality of graphene, which is preferably obtained from graphite through high-pressure exfoliation, weak edge oxidation and intercalation.

[0070] The invention provides a kind of preparation method of micro-nano-scale graphene, it is characterized in that, comprises the following steps:

[0071] 1) After graphite is mixed with a solvent, a graphite premix is obtained;

[0072] 2) After the graphite premix obtained in the above steps is stripped off, an intermediate product is obtained;

[0073] 3) After the intermediate product obtained in the...

Embodiment 1

[0115] Mix 10g of expanded graphite and 990g of NMP evenly, and carry out full solid-liquid mixing in a vacuum defoaming stirring tank for 1 hour. Graphene: concentrated sulfuric acid: potassium permanganate carries out weak oxidation reaction by the mass ratio of 1:100:1, after the graphene after reaction is filtered, according to graphene: potassium sodium tartrate tetrahydrate: deionized water 1:100: The mass ratio of 1 was used for intercalation and stripping experiments. After reacting in a constant temperature water bath at 80°C for 4 hours, it was treated with ultrasonic stirring for 30 minutes to obtain a nano-graphene mixed solution, which was centrifuged at 1000r / min to obtain an upper-layer nano-graphene solution, and then filtered to obtain a nano-graphene solution. Graphene powder.

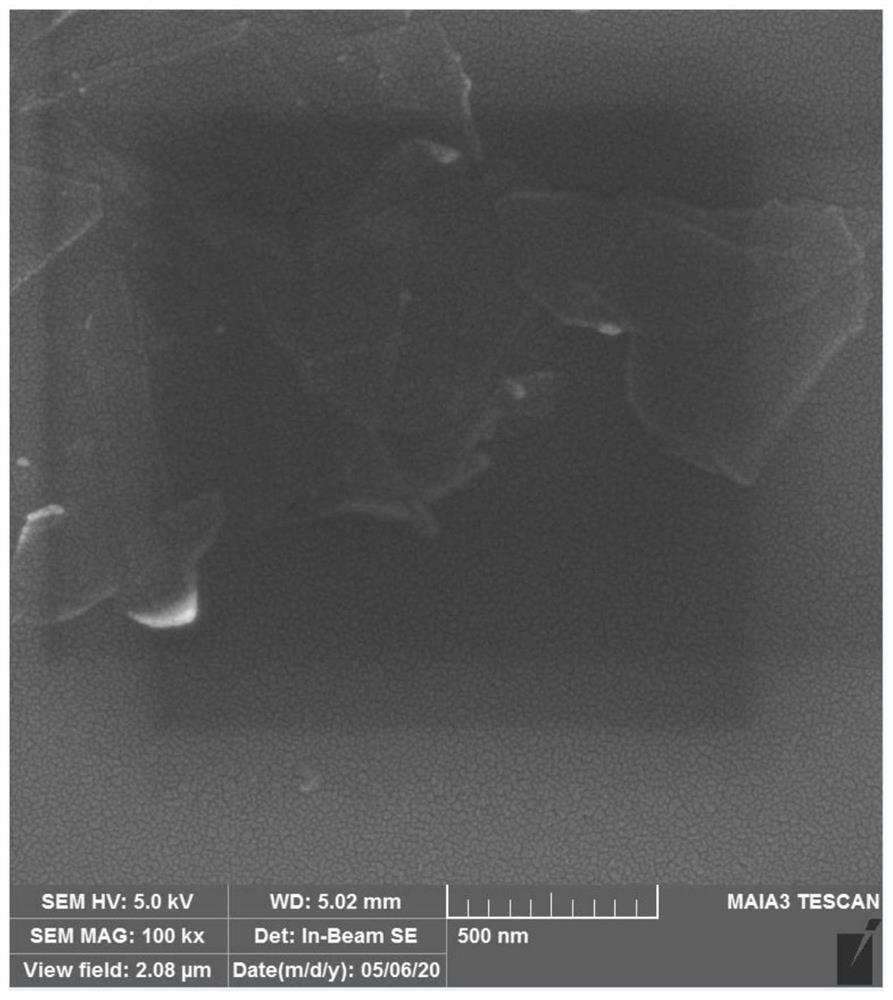

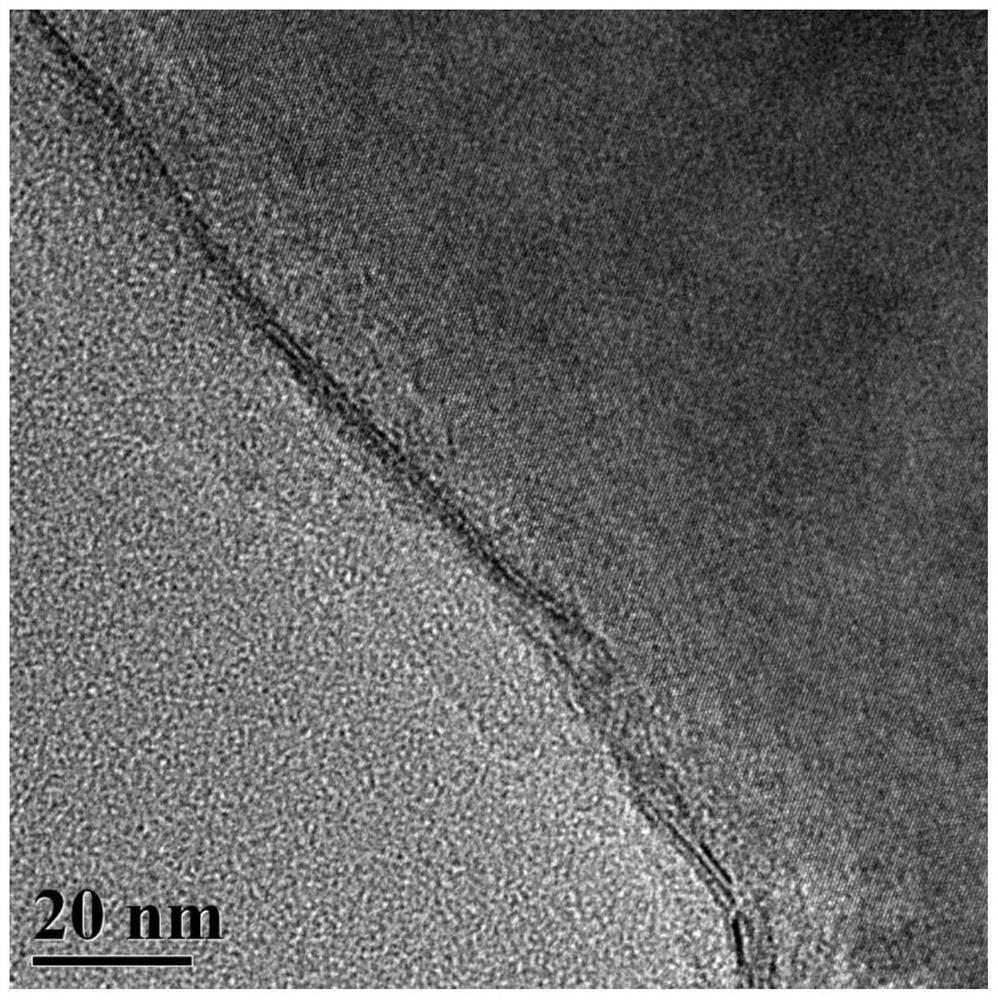

[0116] The micro-nano-scale graphene prepared in Example 1 of the present invention was characterized.

[0117] see figure 1 , figure 1 It is an AFM atomic force microscope sheet r...

Embodiment 2

[0122] Mix 10g of expanded graphite and 990g of NMP evenly, and carry out solid-liquid mixing in a vacuum defoaming stirring tank for 1 hour. The premixed material is crushed and peeled off 5 times by a high-pressure homogenizer under a pressure of 200MPa to prepare a submicron-sized graphene microflake, graphite Graphene: Concentrated sulfuric acid: Potassium permanganate is subjected to a weak oxidation reaction according to the mass ratio of 1:100:1, and the graphene after the reaction is filtered, according to the ratio of graphene: sodium sulfate decahydrate: deionized water 1:100:1 The mass ratio was used for intercalation and stripping experiments. After reacting in a constant temperature water bath at 80°C for 4 hours, it was treated with ultrasonic stirring for 30 minutes to obtain a nano-graphene mixture, which was centrifuged at 1000r / min to obtain an upper-layer nano-graphene solution, and then filtered to obtain nano-graphene. Powder.

[0123] The micro-nano-scale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com