Pipe well post-pouring hole advanced construction pipeline reservation construction system

A technology of tube wells and pipelines, which is applied in the field of tube well post-casting and advance construction pipeline reservation construction system, which can solve the problems of inconvenient concrete transportation, poor construction quality, and difficulty in formwork support, so as to reduce the amount of high-strength concrete and save construction Cost, effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

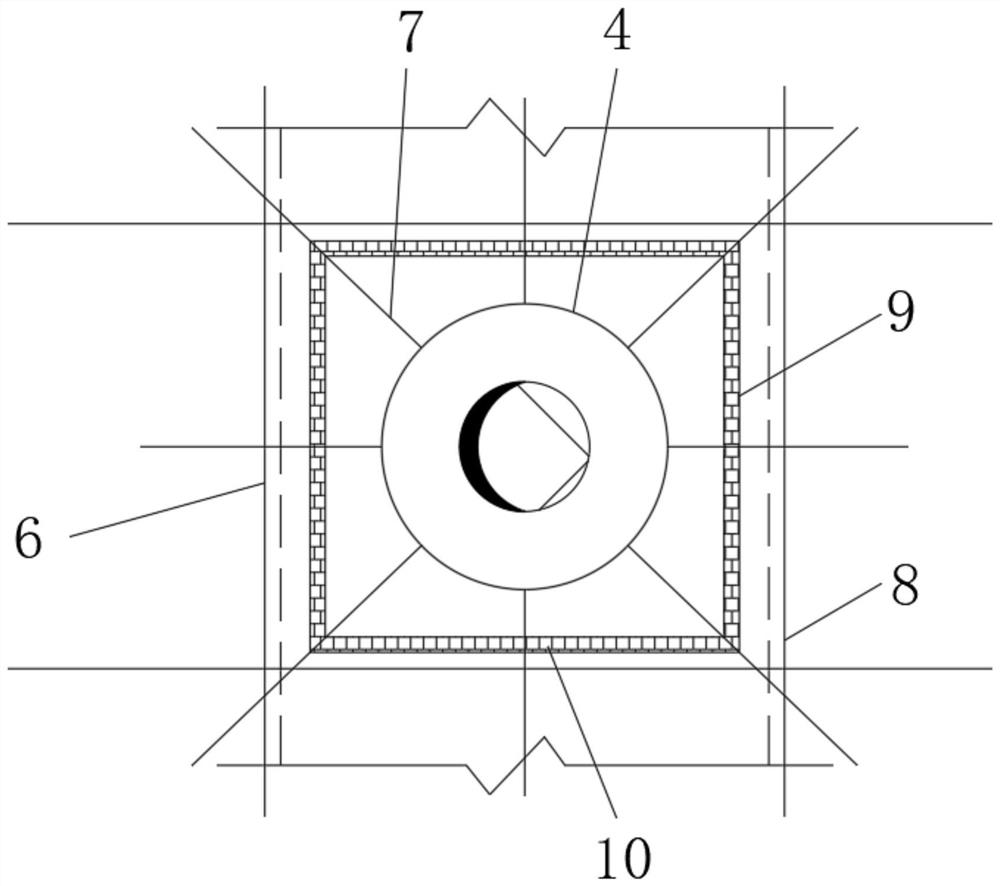

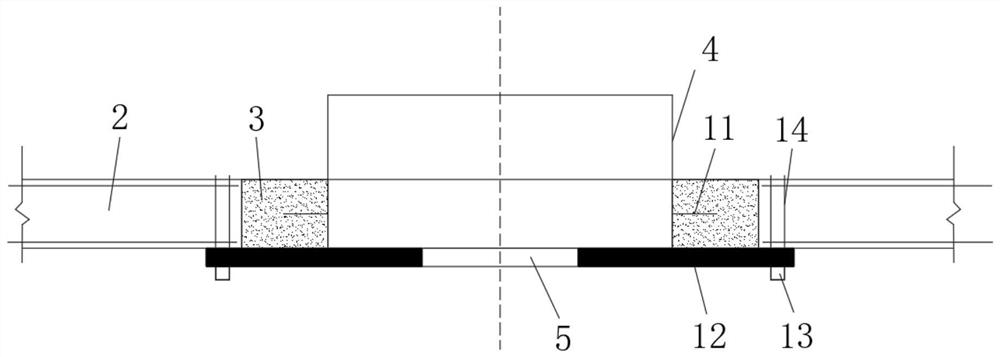

[0038] A tube well post-casting hole advance construction pipeline reservation structure, comprising a tube well formwork 1, a first formwork 2, a second formwork 3 and a post-pouring area 6, the tube well formwork 1 is composed of the first formwork 2, the second formwork 3 and the post-pouring area 6. The post-casting area 6 is composed of a casing 4 and a measuring wire hole 5. The casing 4 is provided with a measuring wire hole 5, and the outer side of the casing 4 is provided with a casing steel bar 7. The outside of the casing steel bar 7 is provided with a plate Reinforcement 8, casing steel reinforcement 7 and plate reinforcement 8 are provided with concrete secondary pouring boundary line 9, inside of concrete secondary pouring boundary line 9 is provided polystyrene board 10, inside second formwork 3 is provided with water stop ring 11 One side of the measurement release hole 5 is provided with a pipeline template 12, one side of the pipeline template 12 is provided w...

Embodiment 2

[0041] A method for reserving pipelines for post-casting tunnels in advance of construction of tube wells, comprising the following steps;

[0042] Step 1. The tube well formwork 1 is erected on the same floor as the structure main body. The first formwork 2 is set up in the same way as the structural slab of this layer. The second formwork 3 is fixed with the ribs 8 in the surrounding pre-cast structural slab through steel wires 14. When the post-casting area 6. When the area is large, wooden square 13 support can be set under the second formwork 3, steel wire 14 bypasses wooden square 13 and pours the surrounding structural plates simultaneously, casing 4 and casing reinforcement 7 are installed synchronously with plate reinforcement 8;

[0043]Step 2: Concrete the tube well structural slabs except the post-pouring area 6, and remove the formwork in the pre-pouring area when the formwork removal strength is reached;

[0044] Step 3. Accurately locate the pipeline by measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com