Water electrolysis hydrogen production device and application thereof

A hydrogen production device and water electrolysis technology, applied in the electrolysis process, electrolysis components, circuits, etc., can solve the problems of high site requirements, high surrounding environment requirements, and no better solutions, achieving simple and portable structure, solving promotion and Limitation of application, effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

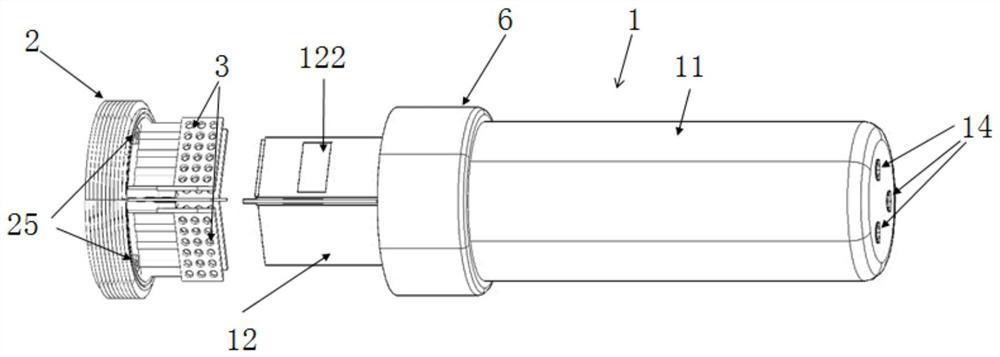

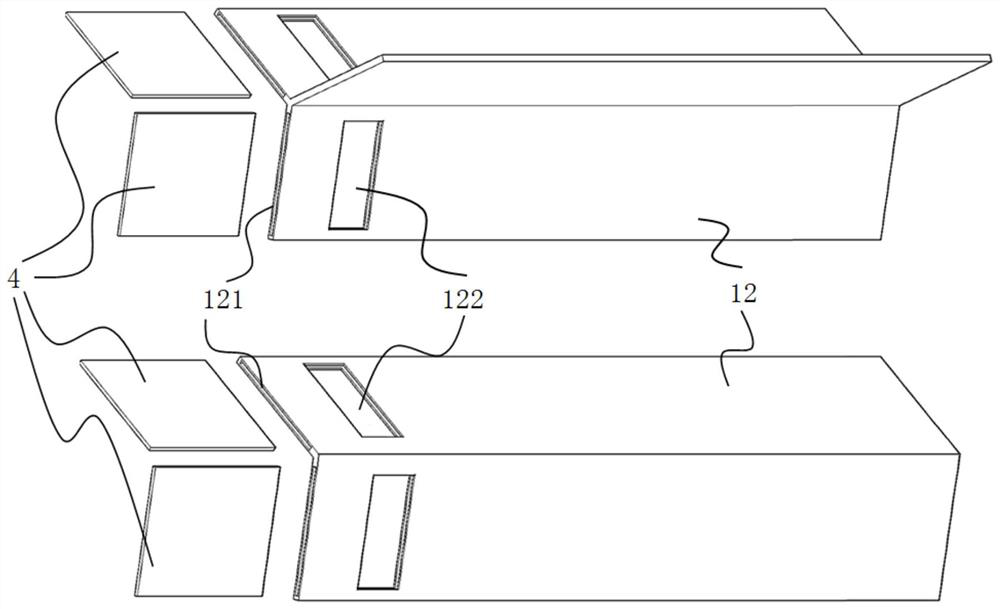

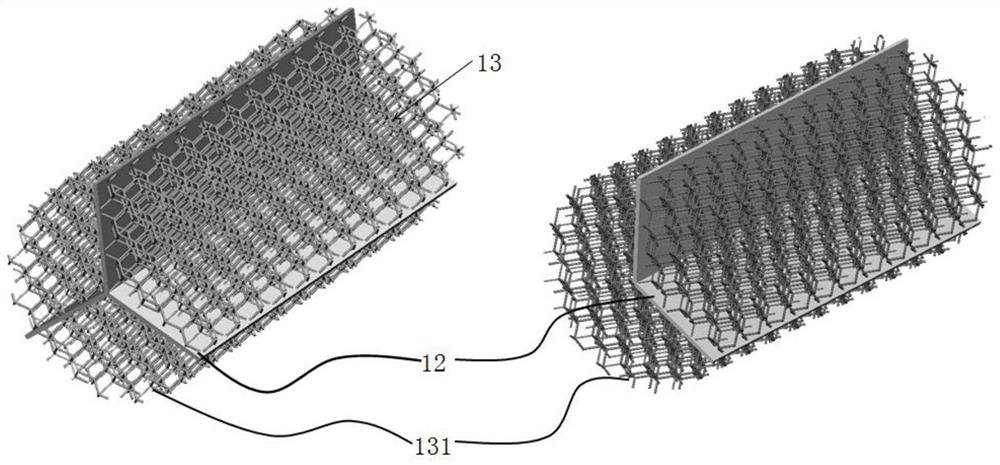

[0122] A cylindrical tank body 1 cavity is divided into Figure 4 Three equal volumes shown, made of PTFE image 3 As shown in the separator 12, the Nafion film is cut to an appropriate size, and from figure 2 The shown electrolytic diaphragm assembly port 121 is inserted into the bottom of the separator 12, and the three Figure 15 The air core 5 shown is installed into the air hole on the top of the tank 1, and then the separated tank 1 is filled with mesh polytetrafluoroethylene; two titanium electrodes coated with Pt / C and one coated with IrO 2 Titanium electrodes installed on Figure 9 On the shown tank body base 2, the tank body 1 is connected with the base, sealed and fastened, forming such as figure 1 The electrolytic cell shown.

Embodiment 2

[0124] A cylindrical tank body 1 cavity is divided into Figure 4 Three equal volumes shown, made of PTFE image 3 Shown separator 12, FAAM-PK-75 membrane (anion exchange membrane) is cut into suitable size, and from figure 2 The shown electrolytic diaphragm assembly port 121 is inserted into the bottom of the separator 12, and the three Figure 15 The air core 5 shown is put into the air hole on the top of the tank body 1, and then the separated tank body 1 is filled with mesh polyethylene; two NiMo electrodes and one nickel electrode coated with NiFeP are installed on the Figure 9 On the shown tank body base 2, the tank body 1 is connected with the base, sealed and fastened, forming such as figure 1 The electrolytic cell shown.

Embodiment 3

[0126] A cylindrical tank body 1 cavity is divided into Figure 4 Shown are two parts in a 1:2 volume ratio, made of PTFE image 3 As shown in the separator 12, the Nafion film is cut to an appropriate size, and from figure 2 The shown electrolytic diaphragm assembly port 121 is inserted into the bottom of the separator 12, and the two Figure 15 The air core 5 shown is installed into the top air hole of the tank body 1, and then the separated tank body 1 is filled with mesh polyethylene; a titanium electrode coated with Pt / C and a titanium electrode coated with IrO 2 Titanium electrodes installed on Figure 9 On the tank body base 2 shown, the tank body 1 and the base are connected, sealed and fastened to form an independent electrolysis unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com