Shot peening carbonitriding treatment method and device

A processing method and technology of processing devices, which are applied in heat treatment furnaces, heat treatment equipment, furnace components, etc., can solve the problems of long process time, increased production costs, and impact on safety of use, etc., to improve the ability to isolate high temperature, improve The effect of quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

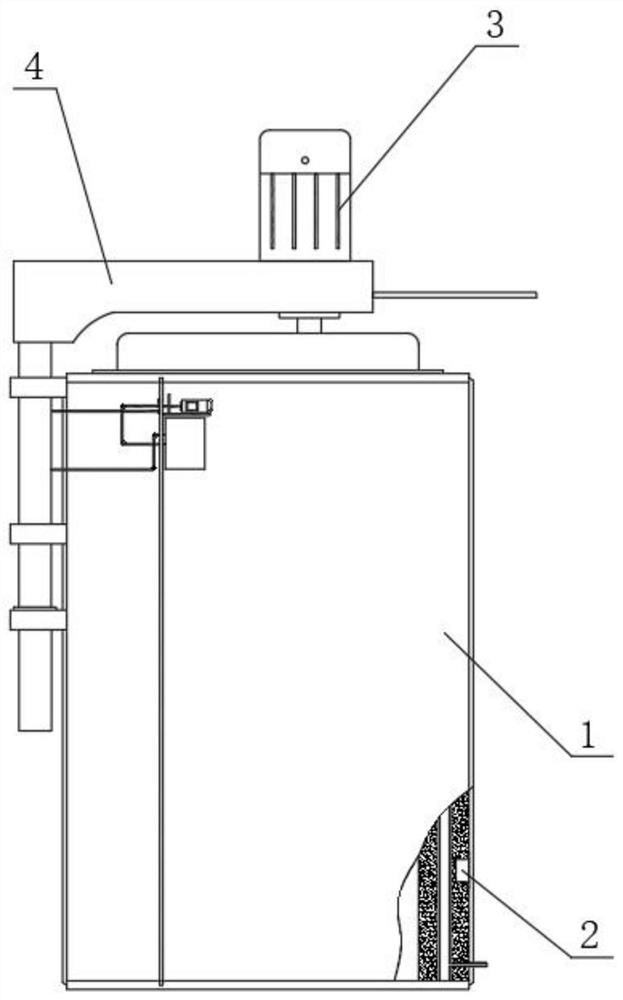

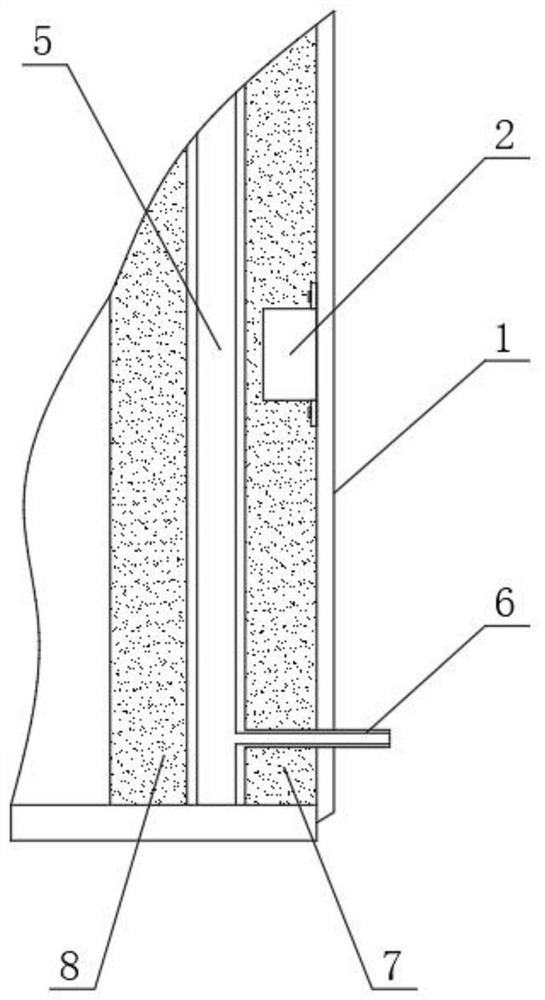

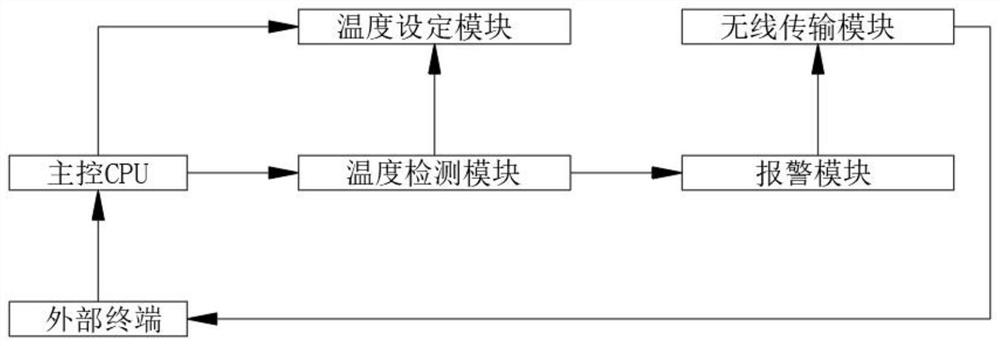

[0026] see Figure 1 to Figure 3 , the present invention provides a technical solution: a shot peening carbonitriding treatment method, including a well-type nitrocarburizing furnace that needs to be used in the treatment method, and the specific steps are as follows:

[0027] Step 1: Shot peening of steel will be selected;

[0028] Step 2: Put the shot that needs to be carbonitrided into the well-type nitrocarburizing furnace, and raise the temperature to 500°C. At this time, the air inside the well-type nitrocarburizing furnace is discharged to form a vacuum;

[0029] Step 3: After continuing to heat up to 600-700°C, add gaseous nitrogen, keep it warm for 3 hours, and then cool with the furnace;

[0030] Step 4: Take out the shot peening of Step 3, put it into the container, and process it by pulsed DC glow discharge plasma heat treatment, and the pressure range during processing is 2000Pa;

[0031] Step 5: Temper the finished product at low temperature, which can relax th...

Embodiment 2

[0039] The difference from Example 1 is that the present invention provides a technical solution: a shot peening carbonitriding treatment method, including a well-type nitrocarburizing furnace that needs to be used in the treatment method, and the specific steps are as follows:

[0040] Step 1: Shot peening of steel will be selected;

[0041] Step 2: Put the shot peening to be carbonitrided into the well-type nitrocarburizing furnace, and raise the temperature to 530°C. At this time, the air inside the well-type nitrocarburizing furnace is discharged to form a vacuum;

[0042] Step 3: After continuing to heat up to 650°C, add gaseous nitrogen and keep it warm for 3.5 hours, then cool with the furnace;

[0043] Step 4: Take out the shot blasting of Step 3, put it into the container, and process it by pulsed DC glow discharge plasma heat treatment, and the pressure range during processing is 3000Pa;

[0044] Step 5: Temper the finished product at low temperature, which can rela...

Embodiment 3

[0049] The difference from the above embodiment is that the present invention provides a technical solution: a shot peening carbonitriding treatment method, including a well-type nitrocarburizing furnace that needs to be used in the treatment method, and the specific steps are as follows:

[0050] Step 1: Shot peening of steel will be selected;

[0051] Step 2: Put the shot that needs to be carbonitrided into the well-type nitrocarburizing furnace and raise the temperature to 550°C. At this time, the air inside the well-type nitrocarburizing furnace is discharged to form a vacuum;

[0052] Step 3: After continuing to heat up to 700°C, add gaseous nitrogen and keep it warm for 4 hours, then cool with the furnace;

[0053] Step 4: Take out the shot blasting of Step 3, put it into the container, and process it by pulsed DC glow discharge plasma heat treatment, and the pressure range during processing is 4000Pa;

[0054] Step 5: Temper the finished product at low temperature, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com