Immobilization of mannase and application of mannase in enzyme reactor

A mannanase and enzyme reactor technology, applied in the directions of immobilized enzymes, glycosylases, enzymes, etc., can solve the problems of complicated preparation, complicated separation of substrates and enzymes, lower relative enzyme activity, etc., and reduce production. cost, realize the reuse of enzymes, and solve the effect of high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

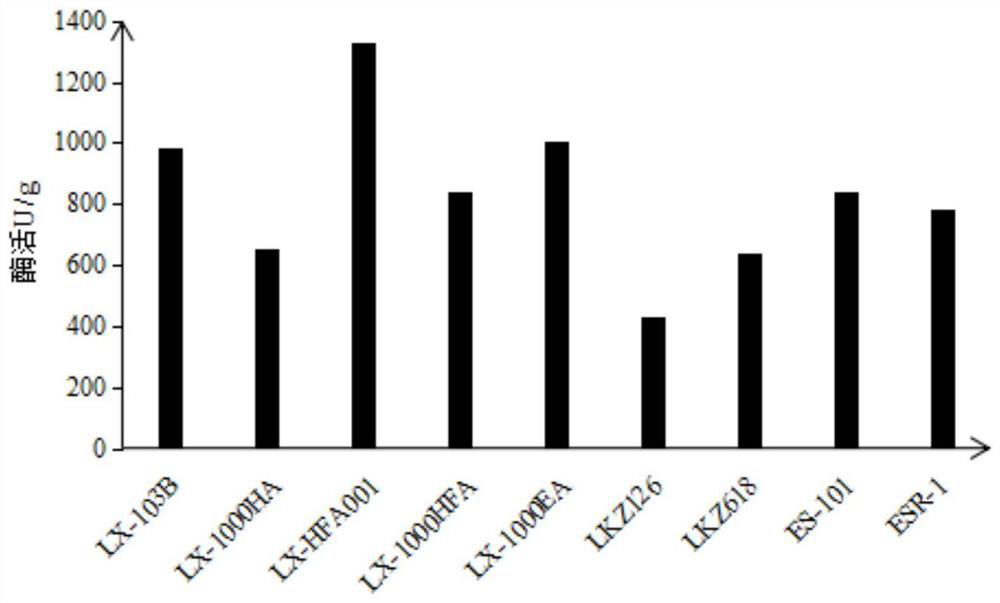

[0047] Example 1 Carrier Screening

[0048] Choose different carriers (Xi'an Lanxiao Technology New Materials Co., Ltd.) LX-103B, LX-1000HA(A), LX-HFA001, LX1000HFA, LX-1000EA, (Aimee Kejian China Biomedical Co., Ltd.) LKZ126, LKZ618, (Tianjin Nankai Hecheng Technology Co., Ltd.) Each 2g of ES-101 and ESR-1 was divided into 150ml Erlenmeyer flasks, and 2g of mannanase was added to each Erlenmeyer flask, and 50mL of 0.1M pH7 phosphate buffer was added. , sealed, placed on a shaker, 25°C, 15rpm, immobilized for 48h. Use a Buchner funnel to extract the liquid, retain the immobilized enzyme, and measure the activity of the immobilized enzyme.

[0049] Measure the immobilized enzyme activity of different carriers, the results are shown in Table 2 and figure 2 :

[0050] Table 2 The results of enzyme activity determination of mannanase immobilized on different carriers

[0051]

[0052] From the above results, it can be seen that LX-HFA001 has the highest enzyme activity, an...

Embodiment 2

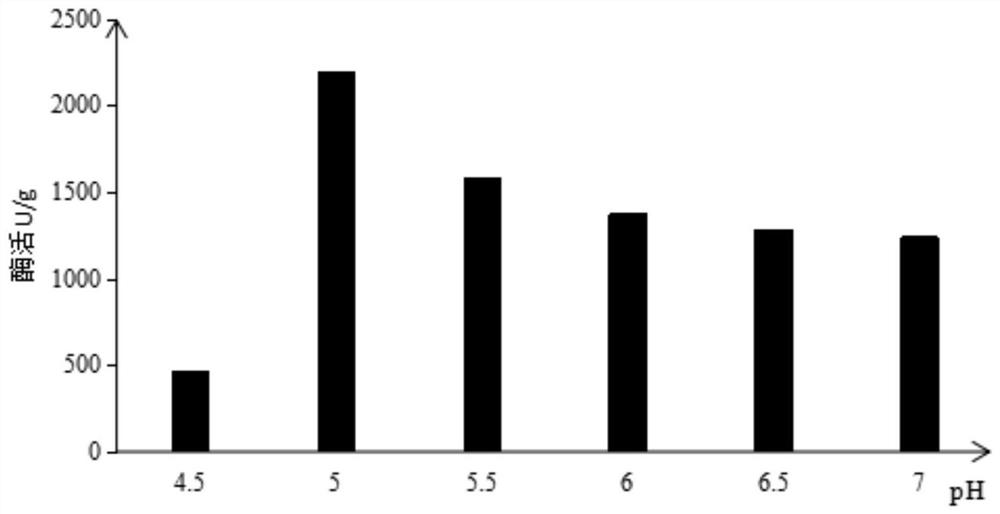

[0053] Embodiment 2 optimal immobilization conditions

[0054] The optimal immobilization conditions were determined by single factor variable method.

[0055] (1) Effects of different concentrations of phosphate on the activity of immobilized enzymes: 0.05M, 0.1M, 0.2M phosphate buffers were selected as buffers, and immobilization conditions were adopted: mannanase (Beijing Guarrun Technology Co., Ltd.) Dry powder 2g, LX-HFA001 carrier 2g, 25°C, pH 7, shake at 150rpm for 48h. Determine the optimal buffer concentration by measuring the activity of the immobilized enzyme.

[0056] The effects of different buffer concentrations on the activity of immobilized enzymes are shown in Table 3.

[0057] Table 3 Effect of different phosphate concentrations on immobilization

[0058]

[0059] It can be seen from the data in Table 3 that different concentrations of phosphate have a greater impact on the enzyme activity of the immobilized enzyme. The optimum concentration is 0.1M. ...

Embodiment 3

[0081] Embodiment 3 immobilized enzyme reactor prepares mannan oligosaccharide

[0082] Enzyme reactor assembly: take an appropriate amount (selected according to the size of the chromatographic column) of immobilized mannanase prepared under optimal conditions, and fill it into the chromatographic column (the filling volume is 2 / 3 of the column volume); Figure 7 The enzyme reactor is assembled as shown.

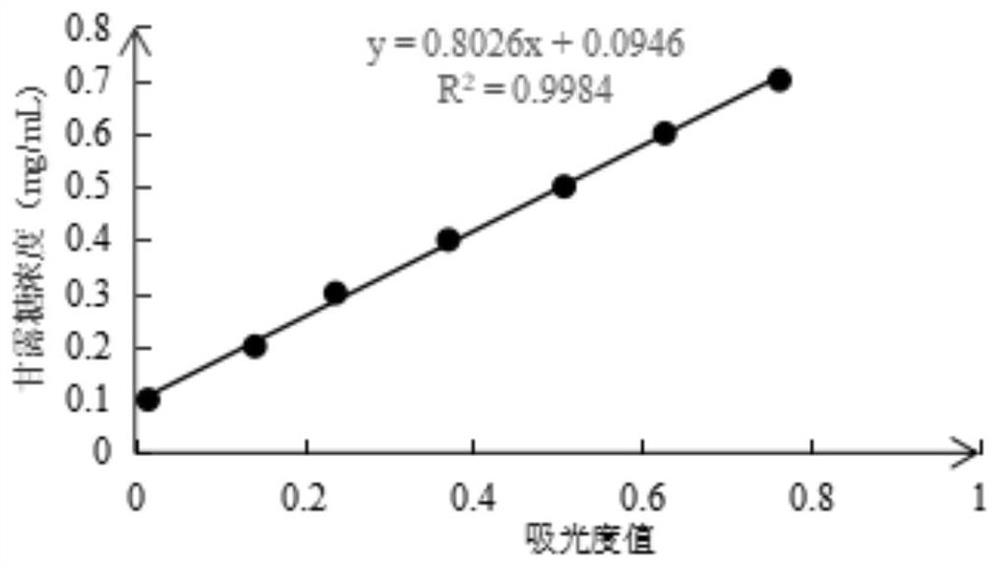

[0083] Detection of mannan oligosaccharides: Use the DNS method to measure the amount of reducing sugar in the reaction solution: take 200 μL of the samples taken and place them in 10 mL centrifuge tubes, then put 200 μL of acetic acid-sodium acetate buffer into the centrifuge tubes solution, then add 500 μL of DNS reagent, shake slightly to mix evenly, plug the cap of the centrifuge tube tightly, heat it in a boiling water bath for 5 minutes, take it out immediately, and quickly cool it to room temperature with flowing cold water, then add deionized Dilute the water to 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com