Composite integral assembly type floor and preparation method thereof

A prefabricated and floor-mounted technology, which is applied in the direction of manufacturing tools, floors, ceramic molding machines, etc., can solve problems such as difficulty in ensuring workers' working time, achieve the effects of reducing manual operation steps and time, high production efficiency, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS It should be understood that the specific embodiments described herein are intended to illustrate and explain the invention and are not intended to limit the invention.

[0035] According to the first aspect of the present disclosure, a method of preparing a composite integral assembly floor can prepare a high strength, a flatness of a well, and a reliable quality, such that workers can greatly reduce labor. Strength, shorten the work time, improve the overall construction efficiency. The preparation method of the floor will be described below with reference to the graphic.

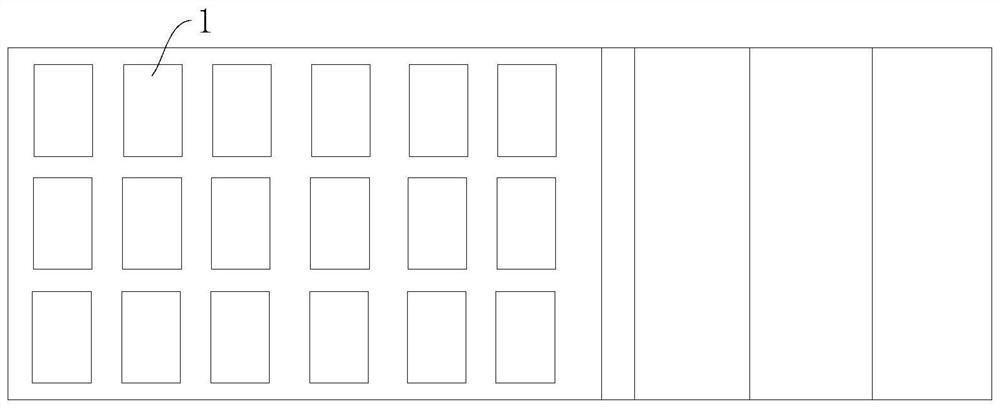

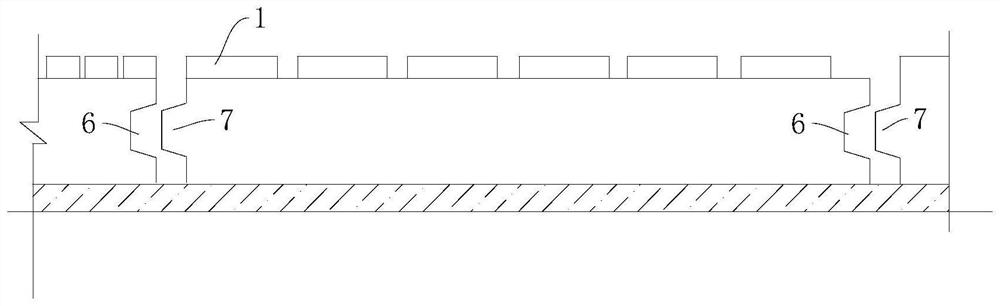

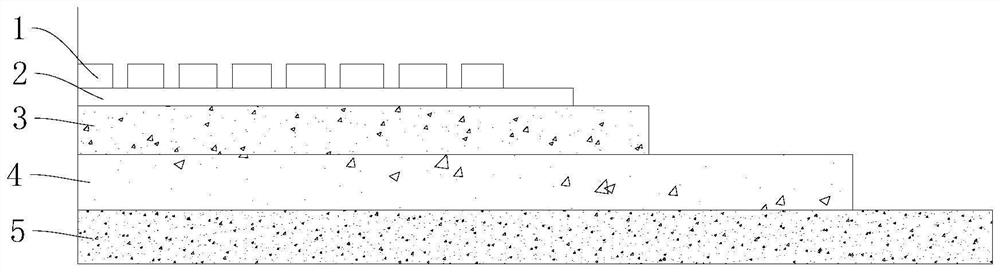

[0036] The preparation method includes the steps of laying the surface layer 1 in the mold, and slurry slurry to the surface layer 1 of the surface layer 1; pouring the aggregate concrete, and placed the steel bars two-way, pouring the crude bones; pouring fine material , Two-way placed steel bars; steam maintenance; draw, to get the floor.

[0037] Thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com