Machining method for tubular part with runner groove

A technology for parts processing and runner grooves, which is applied in the field of tubular parts processing with runner grooves, can solve problems such as deformation of tubular parts, and achieve the effects of reducing deformation, reducing blank deformation, and ensuring dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

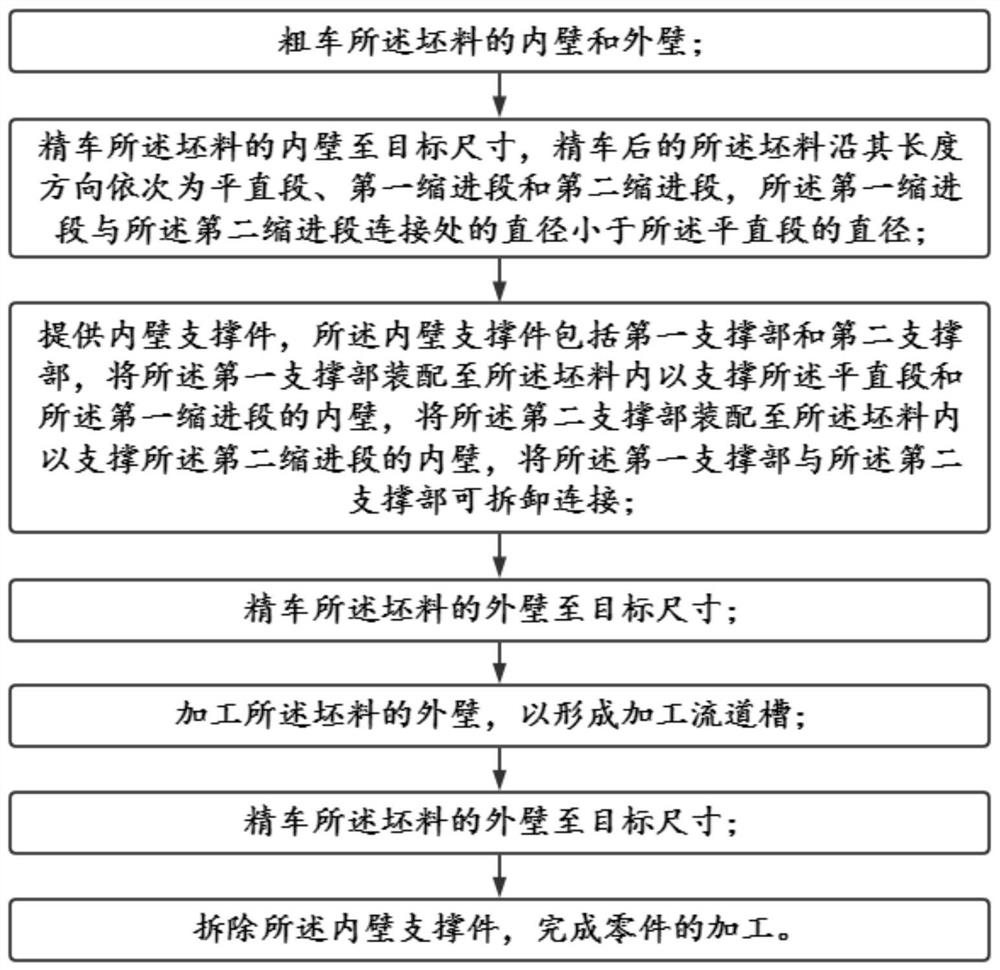

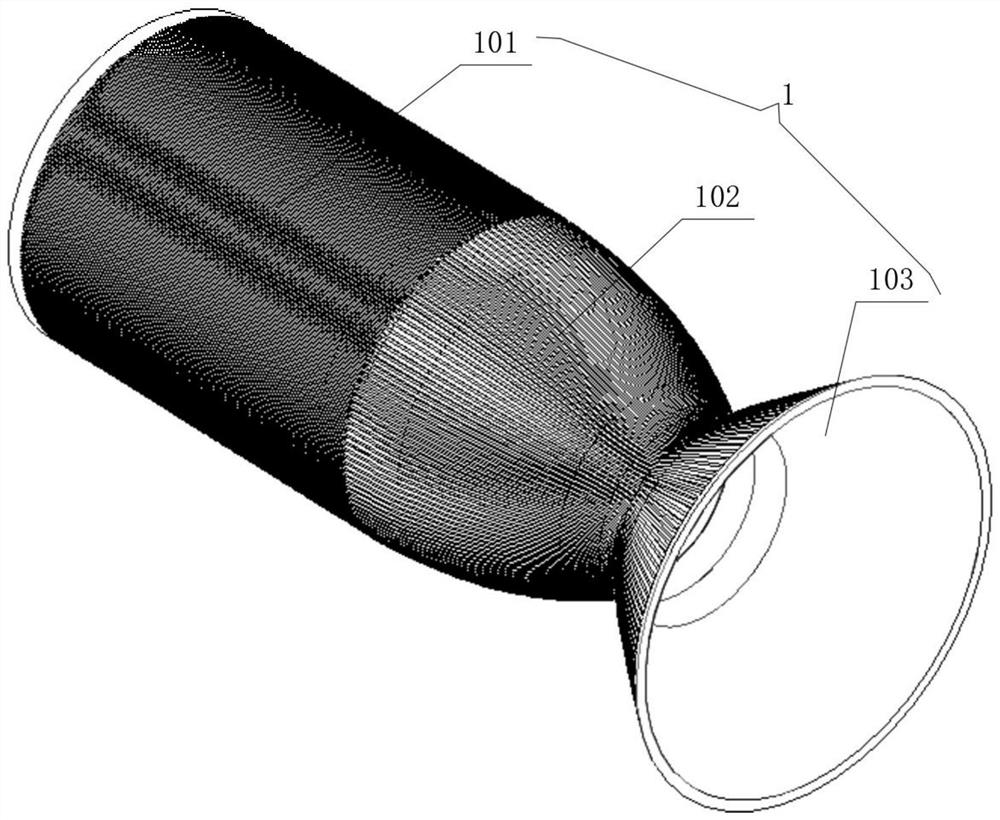

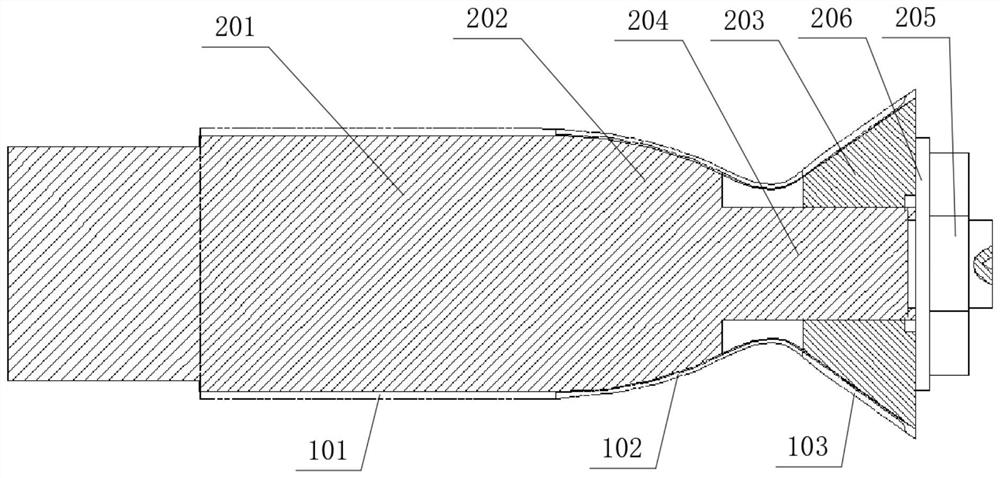

[0035] like Figure 1-Figure 4 As shown, this embodiment provides a method for processing a tubular part with runner grooves, which is used to process a blank into a tubular part 1. The part 1 is a straight section 101, a first indentation section 102 and a second indentation section in sequence. Into the section 103, the diameter of the junction of the first indented section 102 and the second indented section 103 is smaller than the diameter of the straight section 101, and the inner diameter of the straight section 101 is the same along its axial direction, the first indented section 102 and the second indented section 102 The two indented sections 103 are both funnel-shaped, and the opening ends with larger diameters are in opposite directions. It can be understood that referring to figure 2 , Part 1 has a neck, and the diameters of the pipe body on both sides of the neck are larger than the diameter of the neck. The pipe wall of the pipe body of Part 1 is generally thinn...

Embodiment 2

[0057] On the basis of Example 1, this embodiment discloses a specific implementation of a method for processing a tubular part 1 with a runner groove 104. In this embodiment, the blank is a copper alloy, and the wall thickness of the target size of the part 1 is 4.8mm, the inner diameter of the neck is Φ96, 288 grooves with a uniform rib width of 0.9±0.1mm, 144 grooves with a rib width of 1.3±0.1mm and 1.6±0.1mm each, and the remaining wall thickness of the groove is 0.8±0.1mm.

[0058] After rough turning the blank in step 1, in step 2, the inner hole of the neck of the rough turning is Φ90mm, and the unilateral margin of the end face is 10mm. The outer wall of the blank is clamped by the lathe, and the inner hole is aligned within Φ0. The steps of turning, semi-finishing and finishing turning process the inner wall of the straight section 101 and the inner wall of the first indented section 102 of the target size, and the unilateral margin of the end surface is 5 mm. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com