Three-dimensional foamed silver-copper bimetallic sulfide self-supporting film and preparation method thereof

A self-supporting thin-film and foam-like technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of preventing large-scale application and high price, and achieve low price, good effect, and favorable The effect of promotion and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of a three-dimensional foamed silver-copper bimetallic sulfide self-supporting film, comprising the following steps:

[0037] 1) Weighing a certain amount of sulfur source, silver salt, copper salt and surfactant and placing them in a solvent, fully stirring and ultrasonicating;

[0038] 2) Transfer the mixed solution of sulfur source, silver salt, copper salt, surfactant and solvent to a polytetrafluoro-lined reaction kettle or other pressure-resistant container and raise the temperature to 100-200°C, react for 1-72 hours, and then After cooling, a three-dimensional foamed silver-copper bimetallic sulfide self-supporting film is obtained.

[0039]In the present invention, sulfur source, silver salt, copper salt, surfactant and solvent are used as raw materials, and three-dimensional foamy silver-copper bimetallic sulfide self-supporting film is synthesized by simple hydrothermal method or solvothermal method. In the present invention, the sulfur s...

Embodiment 1

[0053] A preparation method of a three-dimensional foamed silver-copper bimetallic sulfide self-supporting film, comprising the following steps:

[0054] Weigh 0.286 gram of silver chloride, 0.050 gram of cuprous chloride, 0.912 gram of thiourea, 0.364 gram of hexadecyltrimethylammonium bromide and add in 55 milliliters of water and stir for 30 minutes, ultrasonic for 60 minutes, and transfer the obtained mixture to Put it into a high-pressure reactor with a polytetrafluoroethylene liner, react at 170°C for 10 hours, and then cool it down to obtain a three-dimensional foam-like silver-copper bimetallic sulfide self-supporting film.

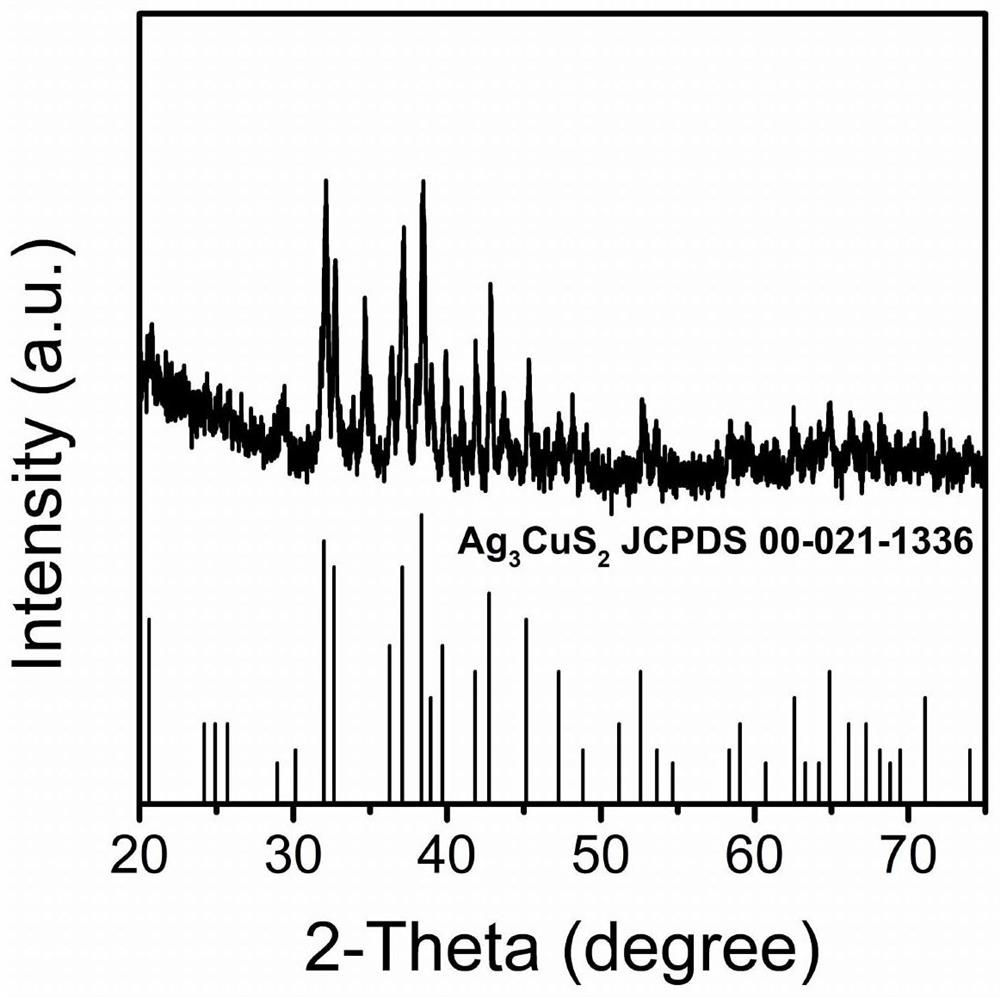

[0055] figure 1 It is the X-ray powder diffraction pattern (XRD) of the three-dimensional foamed silver-copper bimetallic sulfide self-supporting film that the present embodiment prepares, by figure 1 It can be seen that the film prepared in this example is the phase of silver-copper bimetallic sulfide.

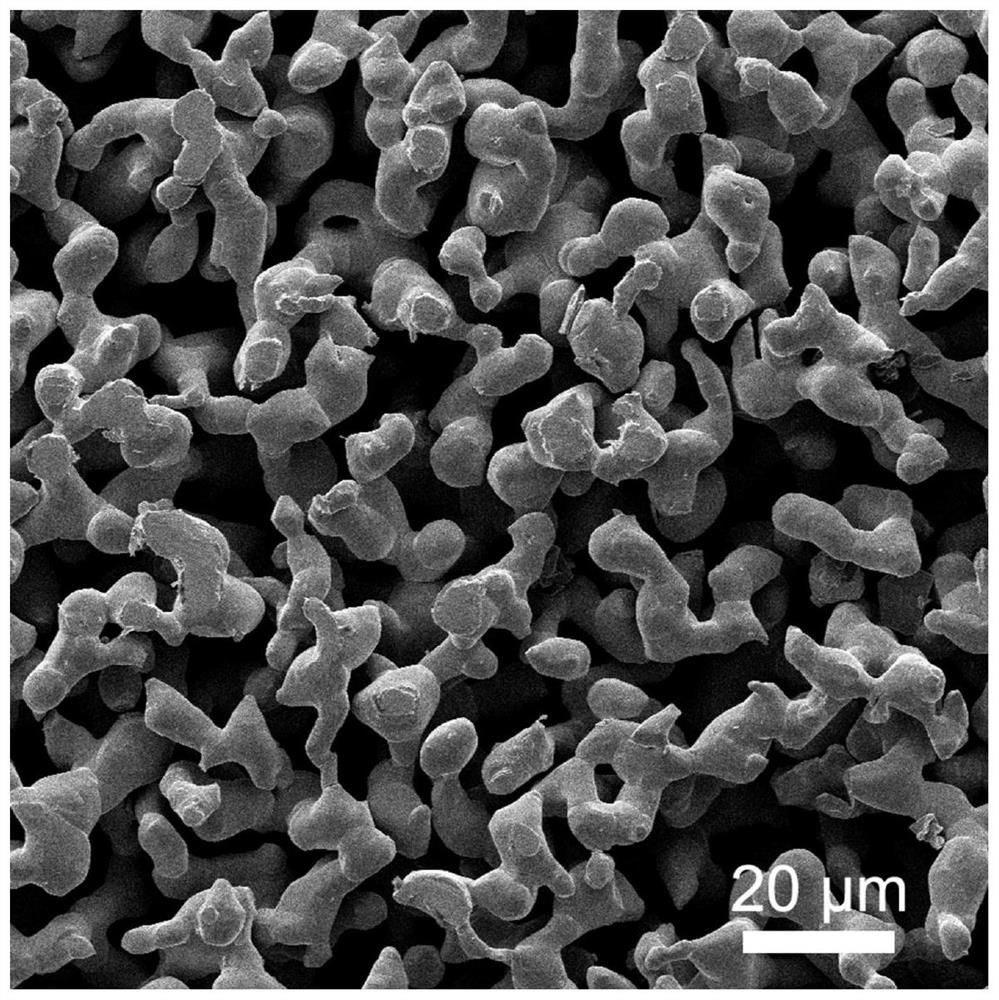

[0056] figure 2 It is an optical photo...

Embodiment 2

[0069] A preparation method of a three-dimensional foamed silver-copper bimetallic sulfide self-supporting film, comprising the following steps:

[0070] Weigh 0.286 g of silver chloride, 0.050 g of cuprous chloride, 0.900 g of thioacetamide, 0.364 g of cetyltrimethylammonium bromide, add 55 ml of water and stir for 30 minutes, ultrasonic for 60 minutes, and the obtained mixture Transfer to a high-pressure reactor lined with polytetrafluoroethylene, react at 170°C for 10 hours, and then cool to obtain a three-dimensional foam-like silver-copper bimetallic sulfide self-supporting film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com