Photocurable compositions having variable viscosities

A composition, light-curing technology, used in the manufacture of tools, stamping cups, dental prostheses, etc., can solve problems such as damage to the mechanical strength of cured polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0159] Preparation and Measurement of Example Composition 1

[0160] All components listed in Table 2 were weighed into a flask and stirred in the dark for 8 hours to 24 hours until all solid contents were dissolved and homogeneous. The viscosity measured at 25°C was about 32 mPa.s.

[0161]In order to evaluate its printability and mechanical strength, a DLP projector with a resolution of 1024×768 (brand and model : Acer P128) as the light source, and use Creation Workshop as the control software] to print dog-shaped stretching rods. Printing was performed with a sheet thickness of 50 μm. The exposure time for each layer is 5800ms. After printing, the print sticks were thoroughly cleaned with isopropanol, air dried and placed in a UV oven for further curing.

[0162] Compressive strength was measured on an Instron 4500 test system by upgrading the control system with Instron's advanced 5500 electronics and software.

[0163] Table 2. Example Composition 1

[0164] ...

Embodiment 2

[0166] Preparation and Measurement of Example Composition 2

[0167] All components listed in Table 3 were weighed into a flask and stirred in the dark for 8 hours to 24 hours until all solid contents were dissolved and homogeneous. The viscosity measured at 25°C was about 42 mPa.s.

[0168] In order to evaluate its printability and mechanical strength, a DLP projector with a resolution of 1024×768 (brand and model : Acer P128) as the light source and use Creation Workshop as the control software] to print dog-shaped stretching rods. Printing was performed with a sheet thickness of 50 μm. The exposure time for each layer is 5800ms. After printing, the print sticks were thoroughly cleaned with isopropanol, air dried and placed in a UV oven for further curing.

[0169] Table 3. Example Composition 2

[0170] components Percentage (weight%) bisphenol A dimethacrylate 35 polyethylene glycol diacrylate 60 Tetrahydrofuryl methacrylate 4 Phenyl...

Embodiment 3

[0172] Preparation and Measurement of Example Composition 3

[0173] All components listed in Table 4 were weighed into a flask and stirred in the dark for 8 hours to 24 hours until all solid contents were dissolved and homogeneous. The viscosity measured at 25°C was about 47 mPa.s.

[0174] In order to evaluate its printability and mechanical strength, a DLP projector with a resolution of 1024×768 (brand and model : Acer P128) as the light source, and use Creation Workshop as the control software] to print dog-shaped stretching rods. Printing was performed with a sheet thickness of 50 μm. The exposure time for each layer is 5800ms. After printing, the print sticks were thoroughly cleaned with isopropanol, air dried and placed in a UV oven for further curing.

[0175] Table 4. Example Composition 3

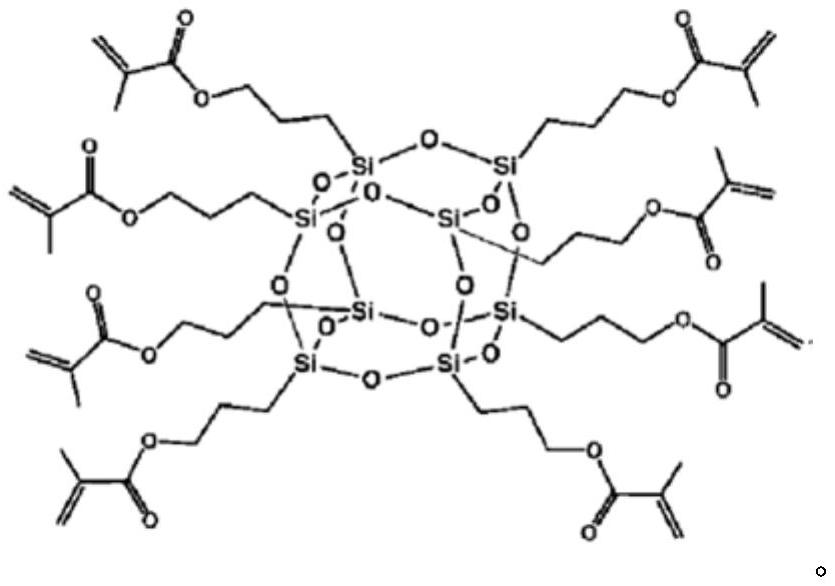

[0176] components Percentage (weight%) Bisphenol A diglycidyl ether methacrylate 50 polyethylene glycol diacrylate 46 Methacryl POSS cage mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com