Efficient etching machine for new energy photovoltaic wafer

A new energy, etching machine technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the service life of etching machines, reducing etching efficiency, and easy splashing of etching liquid, etc., to achieve rapid etching and ensure the effect of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

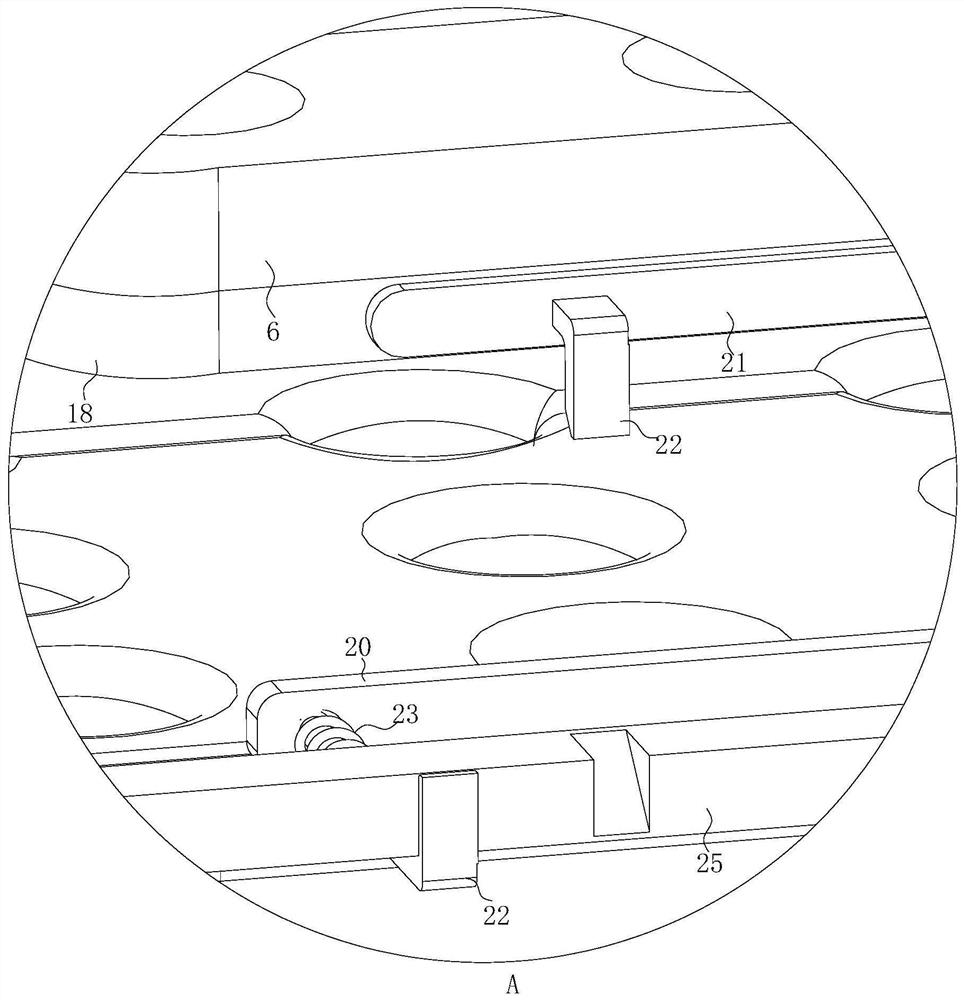

[0027] see Figure 1-8 , the present invention provides a technical solution: a high-efficiency etching machine for new energy photovoltaic wafers, including a protective shell 1, the inner side of the protective shell 1 is provided with a placement mechanism for clamping and placing the photovoltaic wafer, and the left and right sides of the placement mechanism are connected to drive The placement mechanism rotates and transforms the conversion mechanism of the photovoltaic wafer. The placement mechanism moves up and down while being driven by the conversion mechanism and opens the top of the placement mechanism. The top of the protective shell 1 is connected with a spraying mechanism for spraying the etching solution on the photovoltaic wafer. The spray mechanism is located directly above the placement mechanism;

[0028] The placement mechanism includes two first rotating shafts 2, and the two first rotating shafts 2 are respectively rotatably connected to the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com