Laser etching method and system for RFID tag antenna

A technology of RFID tags and laser etching methods, which is applied in the field of laser etching methods and systems for RFID tag antennas, can solve the problems of complex manufacturing process, irregular line edges, and low precision, and achieve simple manufacturing process and reduce The effect of high processing temperature and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

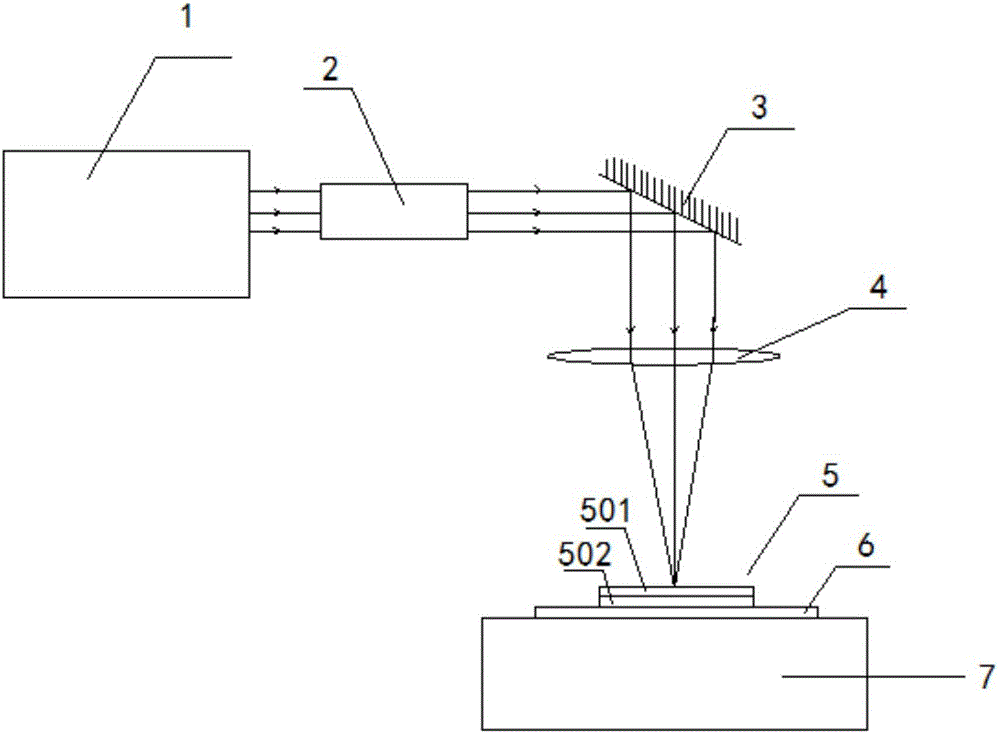

[0018] Such as figure 1 As shown, a laser etching system for an RFID tag antenna includes a laser 1 , a beam expander 2 , a vibrating mirror 3 , a focusing lens 4 , a cooling device 6 and a workbench 7 . In this embodiment, the laser 1 adopts a MOPA fiber laser with a wavelength of 1064nm, a pulse width of 100-200ns, a frequency of 45KHZ, a pulse number of 1500mm / s, and a power of 20w. The zoom factor of the beam expander 2 is 2 times. The focal length of the lens is 160mm, and the format of the focusing lens is 110*110mm, and the cooling device 6 adopts non-woven fabrics that inhale cold water. The focal length of the focusing lens is generally selected as F=160mm, which can increase the power density of the output laser. In practice, select the appropriate lens according to the size of different products. The Gaussian beam from the laser is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com