Underwater cable duct bank laying structure

A technology for underwater cables and cable pipes, which is applied to underwater structures, cable installation, infrastructure engineering, etc. The effect of environmental improvement, short construction period and improved construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

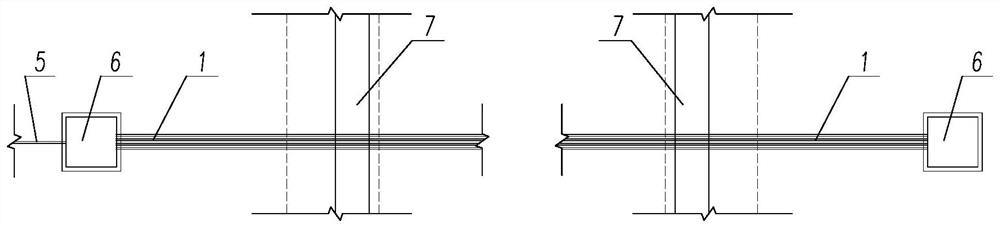

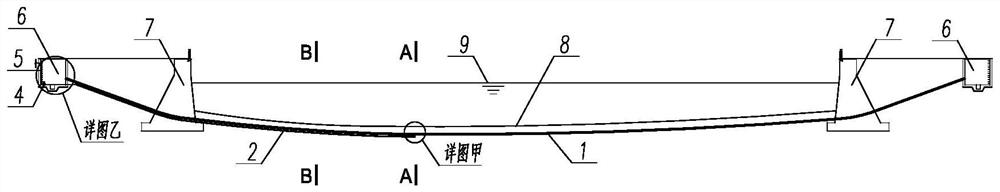

[0026] Such as Figure 1 to Figure 7 As shown, the present invention proposes an underwater cable pipe laying structure, which utilizes the dry land cut and buried pipe construction created by the cofferdam, including cable pipe 1, leakage drainage equipment 2, water level monitoring equipment 3, drainage pump 4, Exhaust pipeline 5 and cable well 6 etc. The cable pipe 1 is laid along the ground line 8 at the bottom of the river, and extends to both banks, passes through the revetment retaining wall 7 and extends into the cable shaft 6; the cable pipe 1 includes a cable pipe 11, an outsourcing reinforced concrete 12, a plain concrete cushion 13, Different diameter tee 14, cable 15 and caulking structure 16.

[0027] The lowest point of the cable pipe 1 is connected to the leakage drainage equipment 2. The leakage drainage equipment 2 includes a drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com