Rapid foaming and filling method for emergency reinforcement of side slope

A foam filling and slope technology, which is applied in excavation, water conservancy projects, artificial islands, etc., can solve problems such as difficulty in meeting emergency reinforcement requirements, long cumulative construction time, and short engineering time, so as to improve slope stability and construction The effect of fast speed and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

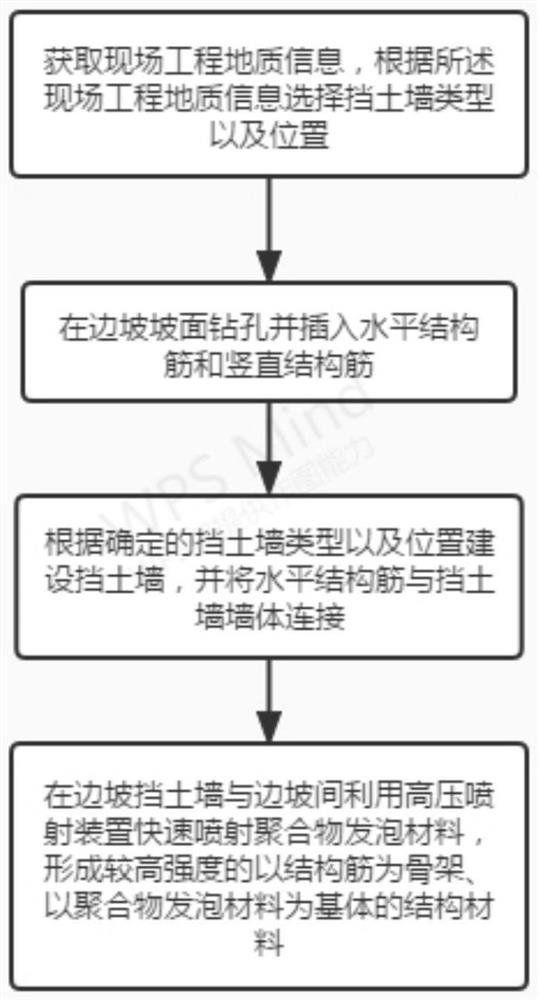

[0050] This embodiment provides a rapid foam filling method for slope emergency reinforcement. The rapid foaming material it belongs to is a polymer foaming material (such as polyurethane, etc.). Include the following steps:

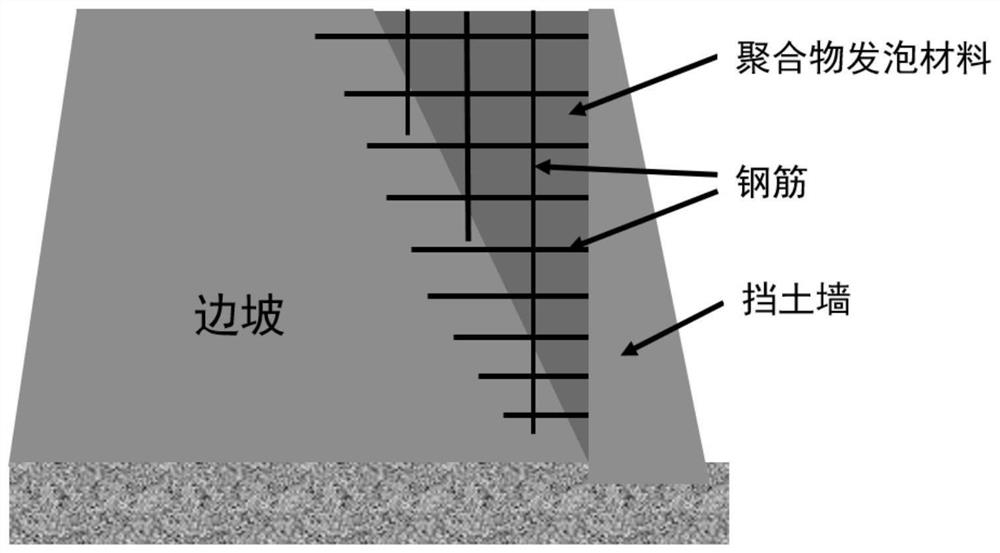

[0051] Step 1: Through on-site inspection of the slope type and engineering geological environment, if the slope is a steep slope, select a higher retaining wall according to relevant specifications, and set the position at the bottom of the slope (see figure 1 ), if the foundation foundation under the retaining wall is average, it needs to be reinforced;

[0052] Step 2: Drill holes horizontally on the slope surface and insert structural reinforcements, then drill holes in the vertical direction and insert anti-rust structural reinforcements. Horizontal structural reinforcements and vertical structural reinforcements are connected with iron wires; structural reinforcements need to be considered The influence of spacing and size; the structural reinfor...

Embodiment 2

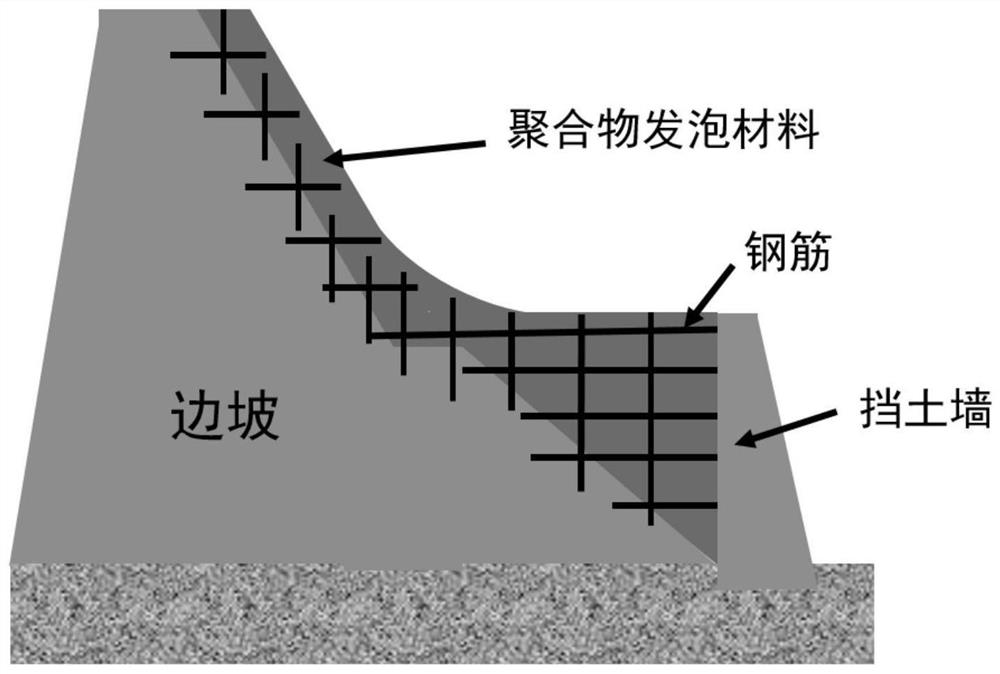

[0057] This embodiment provides a rapid foaming filling method for slope emergency reinforcement, such as image 3 shown, including the following steps:

[0058] Step 1: According to the on-site inspection of the slope type and engineering geological environment, the slope is a gentle slope, and the retaining wall is selected according to the relevant specifications, and the position is set at the bottom of the slope (see figure 2 ), if the foundation foundation under the retaining wall is average, it needs to be reinforced.

[0059] Specifically, the on-site engineering geological information includes the engineering geological environment, the type, location, area, thickness, and degree of danger of the slope; methods for obtaining the on-site engineering geological information include: on-site investigation, on-site survey, and consulting relevant materials.

[0060] The relevant specifications referred to in this embodiment include: "Code for Design of Building Foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com