Method for preparing component gradient composite coating through double-atmosphere self-adaptive reactive sputtering

A composite coating and self-adaptive technology, which is applied in coating, sputtering plating, metal material coating process, etc., can solve the problems of simple metal inclusions, unstable high temperature performance of functional coatings, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

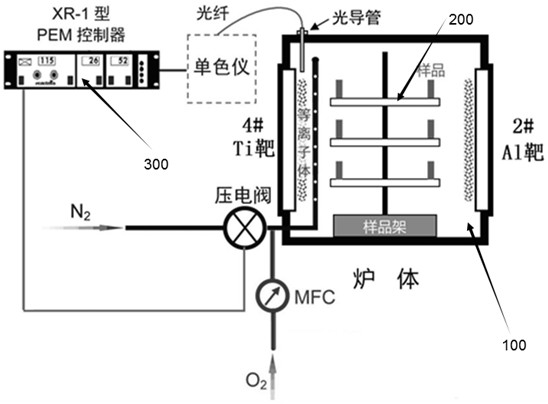

[0033] As shown in the figure, a method for preparing composition-graded composite coatings by dual-atmosphere adaptive reactive sputtering for N 2 -O 2 Dual-atmosphere self-adaptive reactive sputtering process, in which a light pipe connected to a monochromator is provided in the cavity of the sputtering chamber 100 adjacent to the end of the target target; the monochromator is guided into the target through the light pipe The surface plasma region emits a spectrum, and after resolving its intensity, the spectral intensity signal is sent to the reaction atmosphere controller 300, and the reaction atmosphere controller controls the N of the adaptive reaction according to the spectral intensity of the target surface plasma region. 2 supply; the sputtering chamber is also connected with the O 2 The gas path is connected; the mass flowmeter is controlled by O 2 The amount of gas input interferes with the emission spectrum intensity of the target surface plasma region at the tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com