Yellow green afterglow material and preparation method thereof

A yellow-green, afterglow technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unusable, harmful to the body, short afterglow time, etc., and achieve the effects of stable luminescence, superior luminescence performance, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

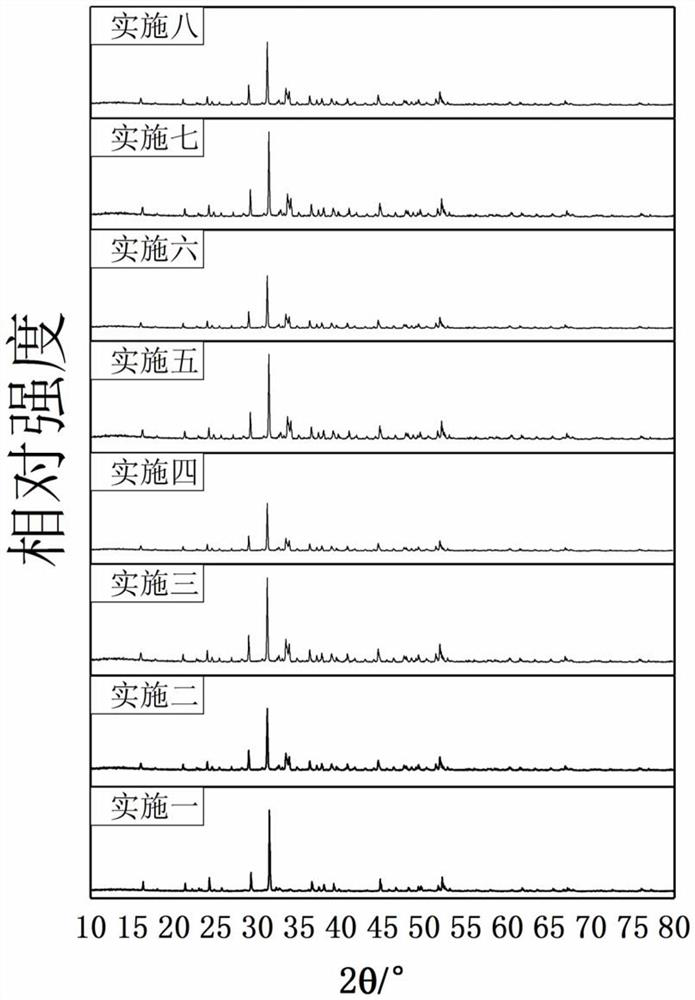

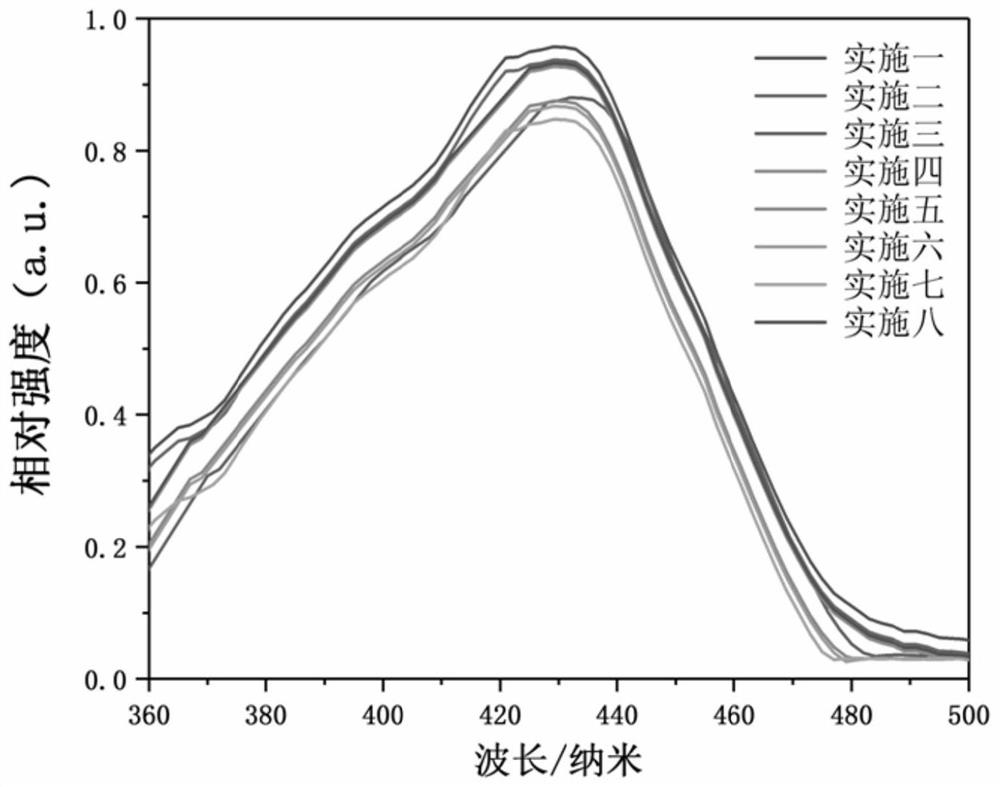

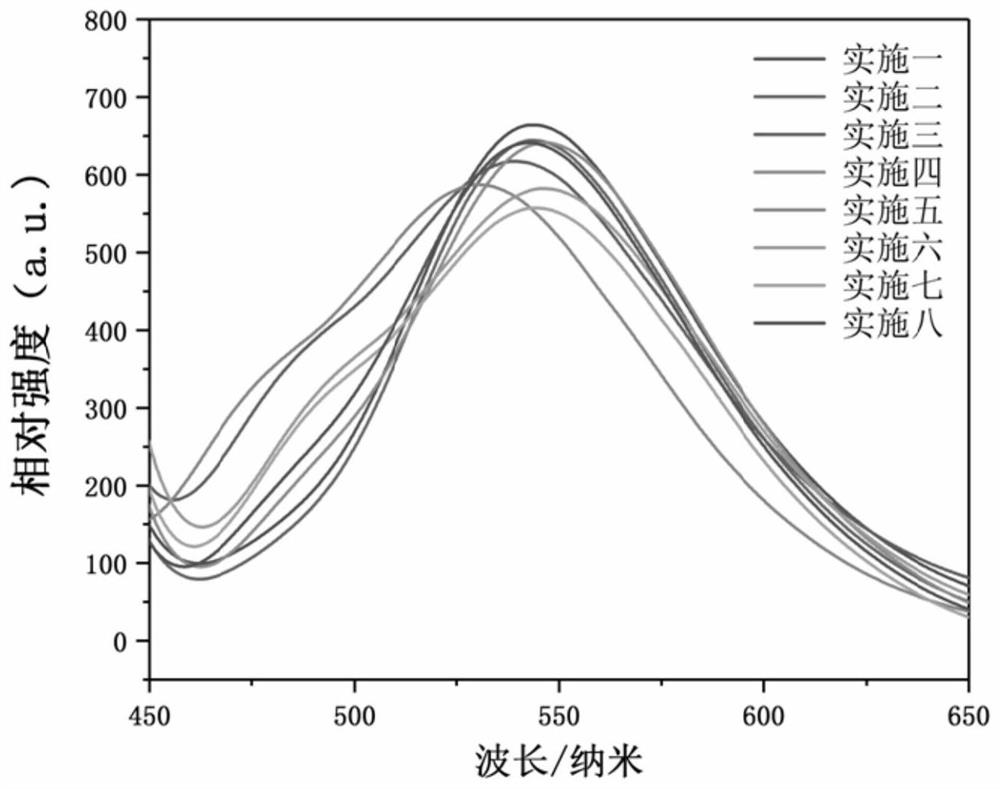

Embodiment 1

[0038] A yellow-green afterglow material, the chemical expression of the afterglow material is: Ca 1.985 MgSi 2 o 7 :0.005Eu 2+ 、0.01Dy 3+ , including the following preparation steps:

[0039] Step 1, weigh CaCO respectively according to the stoichiometric ratio 3 , MgCO 3 , SiO 2 、Eu 2 o 3 、Dy 2 o 3 ;

[0040] Step 2. Mix the weighed raw materials and place them in a ball mill tank, add absolute ethanol to three-quarters of the tank volume, close the lid tightly and place in a ball mill for 4-8 milling at a speed of 600 rpm. hours, take it out and place it in a drying oven, and air-dry it at 120°C for 6 hours to obtain a white precursor;

[0041] Step 3, place the precursor in a corundum crucible, 2 / H 2 Calcined at 1400°C for 6h in an atmosphere of 9 / 1;

[0042] Step 4. Put the calcined yellow-green sample in a ball mill jar and mill it in a ball mill at a speed of 600 rpm for 30 minutes to obtain a yellow-green long afterglow material. After being irradiated ...

Embodiment 2

[0046] A yellow-green afterglow material, the chemical expression of the afterglow material is: Ca 1.985 MgSi 2 o 7 :0.005Eu 2+ 、0.01Dy 3+ , including the following preparation steps:

[0047] Step 1, weigh CaCO respectively according to the stoichiometric ratio 3 , MgCO 3 , SiO 2 、Eu 2 o 3 、Dy 2 o 3 ;

[0048] Step 2. Mix the weighed raw materials and place them in a ball mill tank and add absolute ethanol to three-quarters of the tank volume. Close the lid and place it in a ball mill. Mill at a speed of 600 rpm for 4 -8 hours, take it out, place it in a drying oven, and air-dry it at 120°C for 6 hours to obtain a white precursor;

[0049] Step 3, place the precursor in a corundum crucible, 2 / H 2 Calcined at 1300°C for 8 hours in an atmosphere of 9 / 1;

[0050] Step 4. Put the calcined yellow-green sample in a ball mill jar and mill it in a ball mill for 30 min at a speed of 600 rpm to obtain a yellow-green long afterglow material. After being irradiated by sun...

Embodiment 3

[0053] A yellow-green afterglow material, the chemical expression of the afterglow material is: Ca 1.985 MgSi 2 o 7 :0.005Eu 2+ 、0.01Dy 3+ , including the following preparation steps:

[0054] Step 1, weigh CaCO respectively according to the stoichiometric ratio 3 , MgCO 3 , SiO 2 、Eu 2 o 3 、Dy 2 o 3 ;

[0055] Step 2. Mix the weighed raw materials and place them in a ball mill tank and add absolute ethanol to three-quarters of the tank volume. Close the lid and place it in a ball mill. Mill at a speed of 600 rpm for 4 -8 hours, take it out, place it in a drying oven, and air-dry it at 120°C for 6 hours to obtain a white precursor;

[0056] Step 3, place the precursor in a corundum crucible, 2 / H 2 Calcination at 1200°C for 12h in an atmosphere of 9 / 1;

[0057] Step 4. Put the calcined yellow-green sample in a ball mill jar and mill it in a ball mill at a speed of 600 rpm for 30 minutes to obtain a yellow-green long afterglow material. After being irradiated by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com