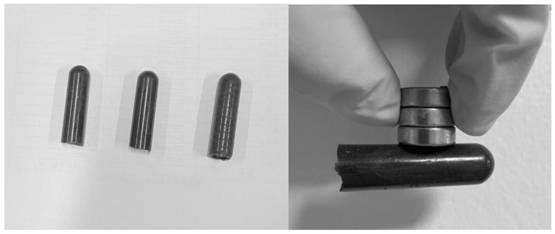

Magnetic writable crayon

A crayon and magnetic technology, applied in pencil leads, household appliances, applications, etc., can solve the problems of single function of crayons, keep writing and painting, and achieve the effect of simple production process, industrialization, easy to organize and temporary placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

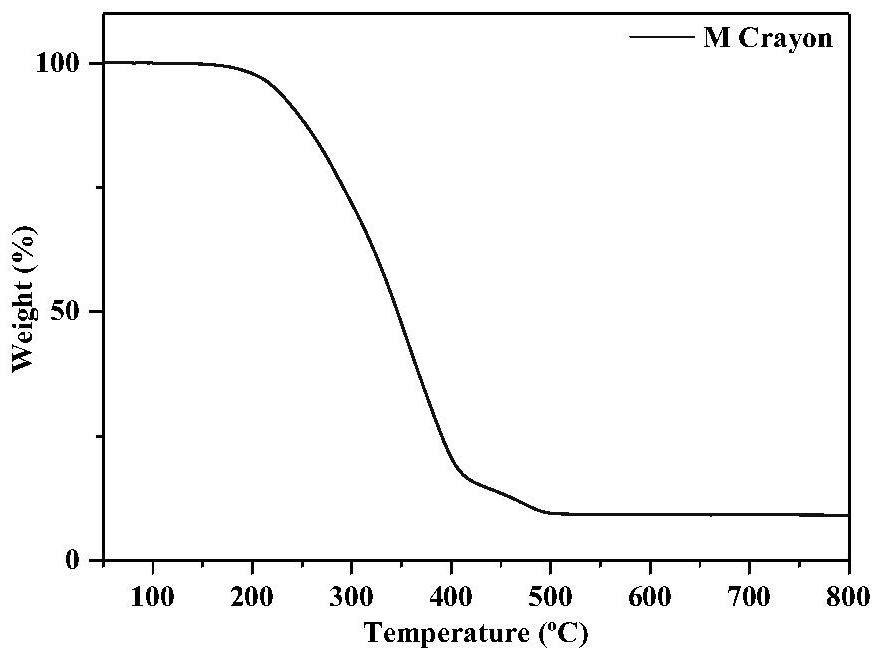

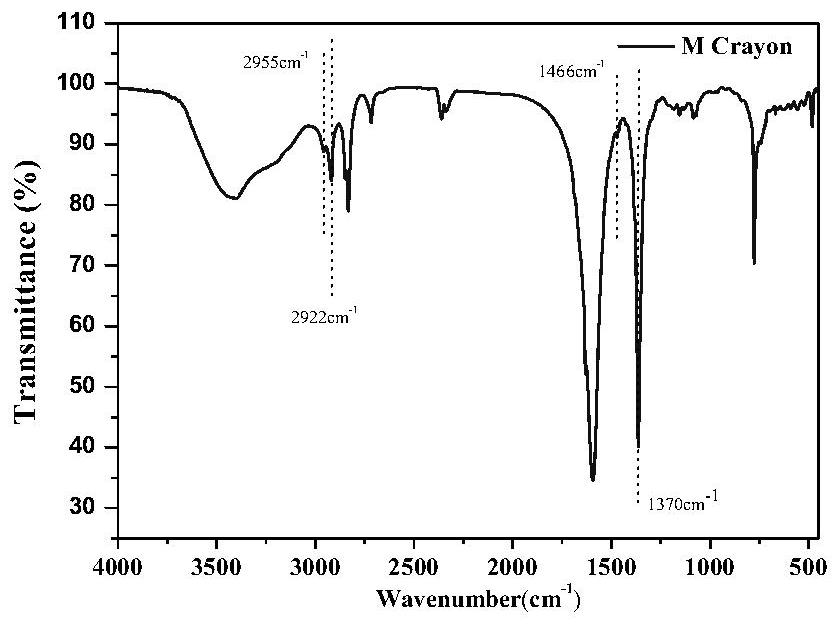

[0019] A magnetic and writeable crayon, its mass ratio is as follows: 10 parts of stearamide, 1 part of stearic acid, 3 parts of glycerin, 2 parts of polyethylene glycol, 30 parts of solid paraffin, 5 parts of polyethylene wax, metal 5 parts of magnetic powder, 5 parts of polyvinyl alcohol, 5 parts of pigment.

[0020] Described preparation method comprises the steps:

[0021] Step 1, preparation of glue: Stir stearamide at 60°C to form a molten state, then add stearic acid and glycerin and continue to stir until molten, and finally add polyethylene glycol and stir to form a molten state to obtain a homogeneous glue ;

[0022] Step 2, preparing synthetic wax: Stir and melt solid paraffin and polyethylene wax at 70°C to obtain a mixture, then add the melted mixture to the homogeneous glue solution and continue stirring for 2-4 hours to obtain sol synthetic wax;

[0023] Step 3, preparing magnetic crayons: Add metal magnetic powder to sol synthetic wax and stir evenly, then ad...

Embodiment 2

[0026] A kind of magnetic writing crayon, its mass ratio is as follows: 15 parts of stearamide, 2 parts of stearic acid, 5 parts of glycerin, 5 parts of polyethylene glycol, 35 parts of solid paraffin, 10 parts of polyethylene wax, metal 10 parts of magnetic powder, 10 parts of polyvinyl alcohol, 8 parts of pigment yellow.

[0027] Described preparation method comprises the steps:

[0028] Step 1, preparation of glue: Stir stearamide at 70°C to form a molten state, then add stearic acid and glycerin and continue to stir until molten, and finally add polyethylene glycol and stir to form a molten state to obtain a homogeneous glue ;

[0029] Step 2, preparing synthetic wax: Stir and melt solid paraffin and polyethylene wax at 100°C to obtain a mixture, then add the melted mixture to the homogeneous glue solution and continue stirring for 4 hours to obtain sol synthetic wax;

[0030] Step 3, preparing magnetic crayons: Add metal magnetic powder to sol synthetic wax and stir eve...

Embodiment 3

[0033] A magnetic writeable crayon, the mass ratio is as follows: 12 parts of stearamide, 2 parts of stearic acid, 4 parts of glycerin, 4 parts of polyethylene glycol, 32 parts of solid paraffin, 8 parts of polyethylene wax, metal 8 parts of magnetic powder, 8 parts of polyvinyl alcohol, 6 parts of pigment.

[0034] Described preparation method comprises the steps:

[0035] Step 1, preparation of glue: Stir stearamide at 65°C to form a molten state, then add stearic acid and glycerin and continue to stir until molten, and finally add polyethylene glycol and stir to form a molten state to obtain a homogeneous glue ;

[0036] Step 2, preparing synthetic wax: Stir and melt solid paraffin and polyethylene wax at 90°C to obtain a mixture, then add the melted mixture to the homogeneous glue solution and continue stirring for 3 hours to obtain sol synthetic wax;

[0037] Step 3, preparing magnetic crayons: Add metal magnetic powder to sol synthetic wax and stir evenly, then add pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com