MXene-graphene-PVC composite material and preparation method thereof

A composite material and graphene technology, which is applied in the field of MXene-graphene-PVC composite material and its preparation, can solve problems such as graphene agglomeration, and achieve the effects of improved toughness, good economic performance, and simple and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

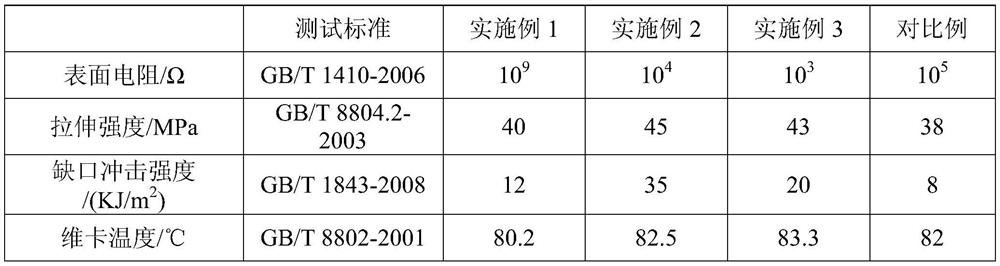

Examples

Embodiment 1

[0029] An MXene-graphene-PVC composite material, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 3 parts of calcium-zinc composite stabilizer, 8 parts of chlorinated polyethylene, 1 part of ACR processing aid, 10 parts of nano calcium carbonate , 0.2 parts of PE wax, 0.3 parts of monoglyceride, 0.2 parts of OPE wax, 1 part of MXene-graphene, 0.2 parts of antioxidant 1010.

[0030] Described MXene-graphene obtains by following preparation method:

[0031] (i) Disperse the aminoanthraquinone solid in absolute ethanol by ultrasound, and filter with gauze to remove insoluble matter. Ultrasonic disperse the filtered solution and graphene evenly to obtain a uniform solution A; wherein the mass ratio of graphene to aminoanthraquinone is 1:10. Put solution A in an oil bath at 78°C and stir to reflux for 36 hours, then remove the remaining aminoanthraquinone and absolute ethanol by centrifugation, and then disperse into deionized water to obtain solu...

Embodiment 2

[0039] A MXene-graphene-PVC composite material, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 4 parts of calcium-zinc composite stabilizer, 12 parts of chlorinated polyethylene, 2.5 parts of ACR processing aid, 8 parts of nano calcium carbonate , 0.3 parts of PE wax, 0.3 parts of monoglyceride, 0.2 parts of OPE wax, 3 parts of MXene-graphene, 0.2 parts of antioxidant 1010.

[0040] Described MXene-graphene obtains by following preparation method:

[0041] (i) Disperse the aminoanthraquinone solid in absolute ethanol by ultrasound, and filter with gauze to remove insoluble matter. Ultrasonic disperse the filtered solution and graphene evenly to obtain a uniform solution A; wherein the mass ratio of graphene to aminoanthraquinone is 1:12. Put solution A in an oil bath at 78°C and stir to reflux for 36 hours, then remove the remaining aminoanthraquinone and absolute ethanol by centrifugation, and then disperse into deionized water to obtain s...

Embodiment 3

[0049] A MXene-graphene-PVC composite material, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 4 parts of calcium-zinc composite stabilizer, 15 parts of chlorinated polyethylene, 2 parts of ACR processing aid, 20 parts of nano calcium carbonate , 0.4 parts of PE wax, 0.5 parts of monoglyceride, 0.3 parts of OPE wax, 5 parts of MXene-graphene, 0.2 parts of antioxidant 1010.

[0050] Described MXene-graphene obtains by following preparation method:

[0051] (i) Disperse the aminoanthraquinone solid in absolute ethanol by ultrasound, and filter with gauze to remove insoluble matter. Ultrasonic disperse the filtered solution and graphene evenly to obtain a uniform solution A; wherein the mass ratio of graphene to aminoanthraquinone is 1:8. Put solution A in an oil bath at 78°C and stir to reflux for 36 hours, then remove the remaining aminoanthraquinone and absolute ethanol by centrifugation, and then disperse into deionized water to obtain sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com