Composite system high-voltage low-loss piezoelectric ceramic and preparation method thereof

A technology of piezoelectric ceramics and high voltage, applied in the field of piezoelectric ceramics, can solve problems such as low piezoelectric constant, failure to meet application needs, and large loss, and achieve reduced dielectric loss, high practical value, and excellent piezoelectric constant Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

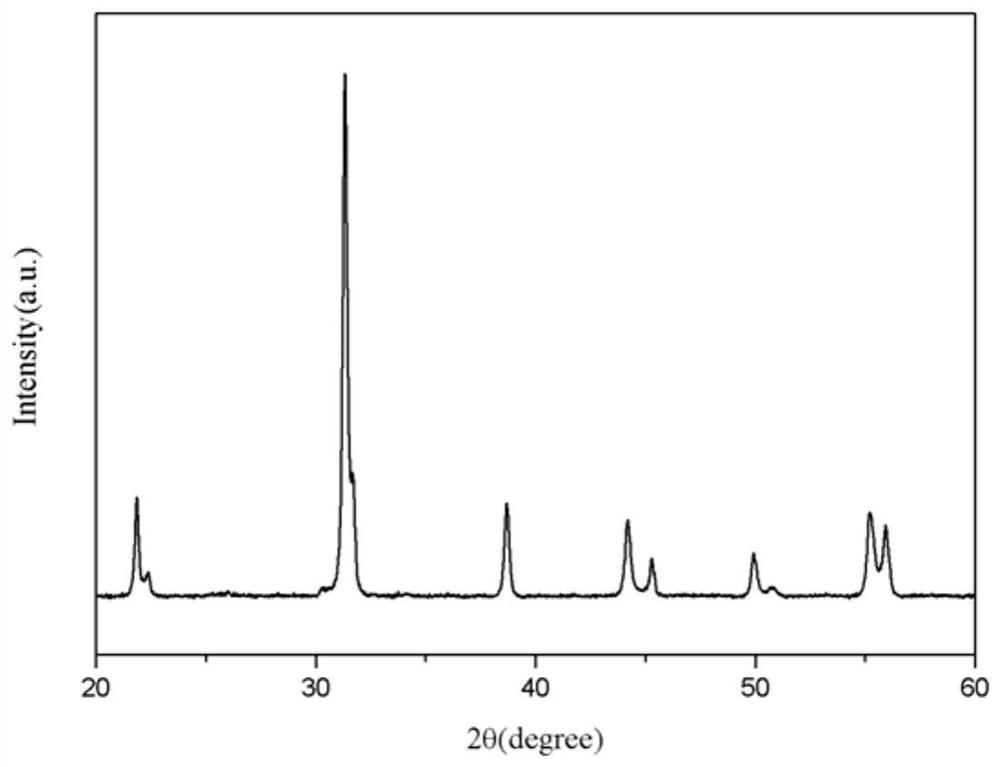

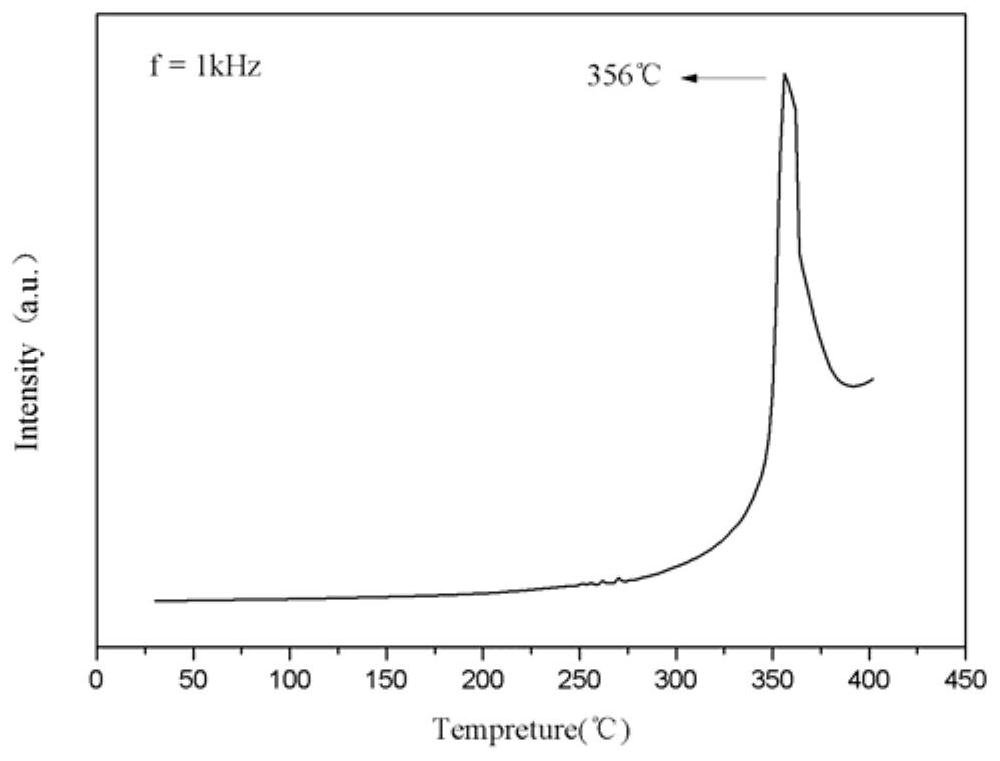

Image

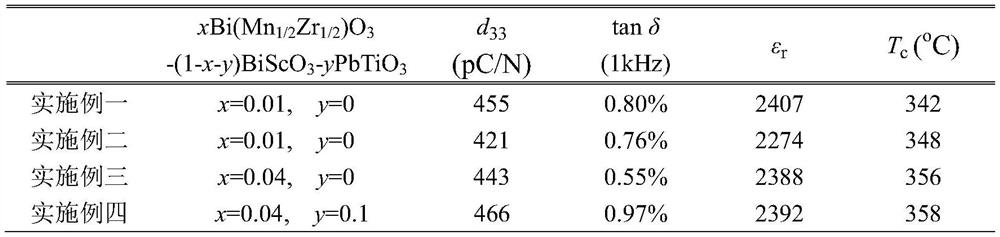

Examples

Embodiment 1

[0037] Preparation formula molecular formula is:

[0038] xBi(Zr 1 / 2 Ni 1 / 2 )O 3 -(0.1-x)Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.9Pb(Zr 0.51 Ti 0.49 )O 3 +y%CeO 2 , x=0.01, y=0 modified piezoelectric ceramics.

[0039] Namely: 0.01Bi(Zr 1 / 2 Ni 1 / 2 )O 3 -0.09Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.9Pb(Zr 0.51 Ti 0.49 )O 3

[0040] The preparation method is:

[0041] Step 1: Using NiO, Bi 2 o 3 , ZrO 2 , ZnO, Nb 2 o 5 , Pb 3 o 4 、TiO 2 , CeO2 As raw materials, according to the stoichiometric ratio of Ni, Bi, Zr, Zn, Nb, Pb, Ti, Ce in the formula formula;

[0042] Step 2: Put the prepared powder into the ball mill tank of the planetary ball mill and mix ball milling for 13 hours. The speed of the planetary ball mill is 250r / min to obtain the powder after ball milling;

[0043] Step 3: pre-calcining the ball-milled powder at 850°C for 3 hours to obtain the pre-calcined powder;

[0044] Step 4: Perform secondary ball milling on the pre-burned powder for 24 hours, then take the mate...

Embodiment 2

[0051] Preparation formula molecular formula is:

[0052] xBi(Zr 1 / 2 Ni 1 / 2 )O 3 -(0.1-x)Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.9Pb(Zr 0.51 Ti 0.49 )O 3 +y%CeO 2 , x=0.02, y=0 modified piezoelectric ceramics.

[0053] Namely: 0.02Bi(Zr 1 / 2 Ni 1 / 2 )O 3 -0.08Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.9Pb(Zr 0.51 Ti 0.49 )O 3

[0054] The preparation method is:

[0055] Step 1: Using NiO, Bi 2 o 3 , ZrO 2 , ZnO, Nb 2 o 5 , Pb 3 o 4 、TiO 2 , CeO 2 As raw materials, according to the stoichiometric ratio of Ni, Bi, Zr, Zn, Nb, Pb, Ti, Ce in the formula formula;

[0056] Step 2: Put the prepared powder into the ball mill tank of the planetary ball mill and mix ball milling for 13 hours. The speed of the planetary ball mill is 250r / min to obtain the powder after ball milling;

[0057] Step 3: pre-calcining the ball-milled powder at 850°C for 3 hours to obtain the pre-calcined powder;

[0058] Step 4: Perform secondary ball milling on the pre-burned powder for 24 hours, then take the ma...

Embodiment 3

[0065] Preparation formula molecular formula is:

[0066] xBi(Zr 1 / 2 Ni 1 / 2 )O 3 -(0.1-x)Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.9Pb(Zr 0.51 Ti 0.49 )O 3 +y%CeO 2 , x=0.04, y=0 modified piezoelectric ceramics.

[0067] Namely: 0.04Bi(Zr 1 / 2 Ni 1 / 2 )O 3 -0.06Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.9Pb(Zr 0.51 Ti 0.49 )O 3

[0068] The preparation method is:

[0069] Step 1: Using NiO, Bi 2 o 3 , ZrO 2 , ZnO, Nb 2 o 5 , Pb 3 o 4 、TiO 2 , CeO 2 As raw materials, according to the stoichiometric ratio of Ni, Bi, Zr, Zn, Nb, Pb, Ti, Ce in the formula formula;

[0070] Step 2: Put the prepared powder into the ball mill tank of the planetary ball mill and mix ball milling for 13 hours. The speed of the planetary ball mill is 250r / min to obtain the powder after ball milling;

[0071] Step 3: pre-calcining the ball-milled powder at 850°C for 3 hours to obtain the pre-calcined powder;

[0072] Step 4: Perform secondary ball milling on the pre-burned powder for 24 hours, then take the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com