Lamination diaphragm covering device and film covering and tension detecting process thereof

A technology of tension detection and diaphragm, applied in the direction of tension measurement, sustainable manufacturing/processing, electrochemical generator, etc., can solve problems such as inconsistent surface flatness, and achieve the effect of improving film coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

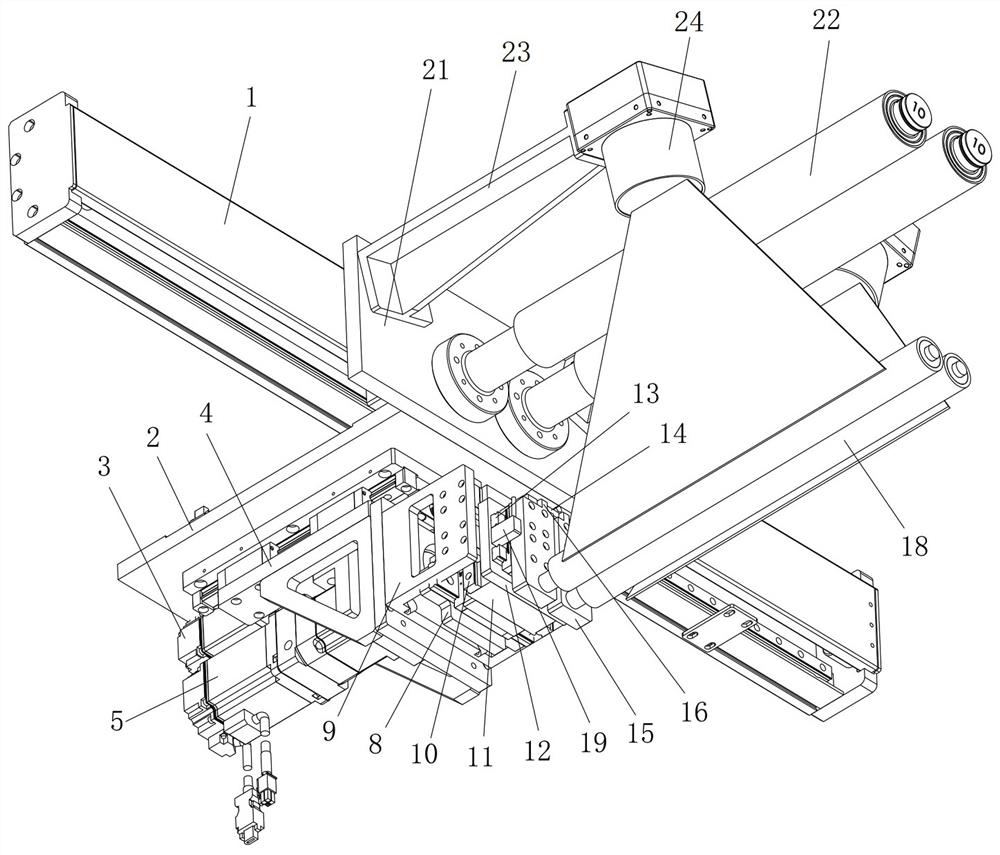

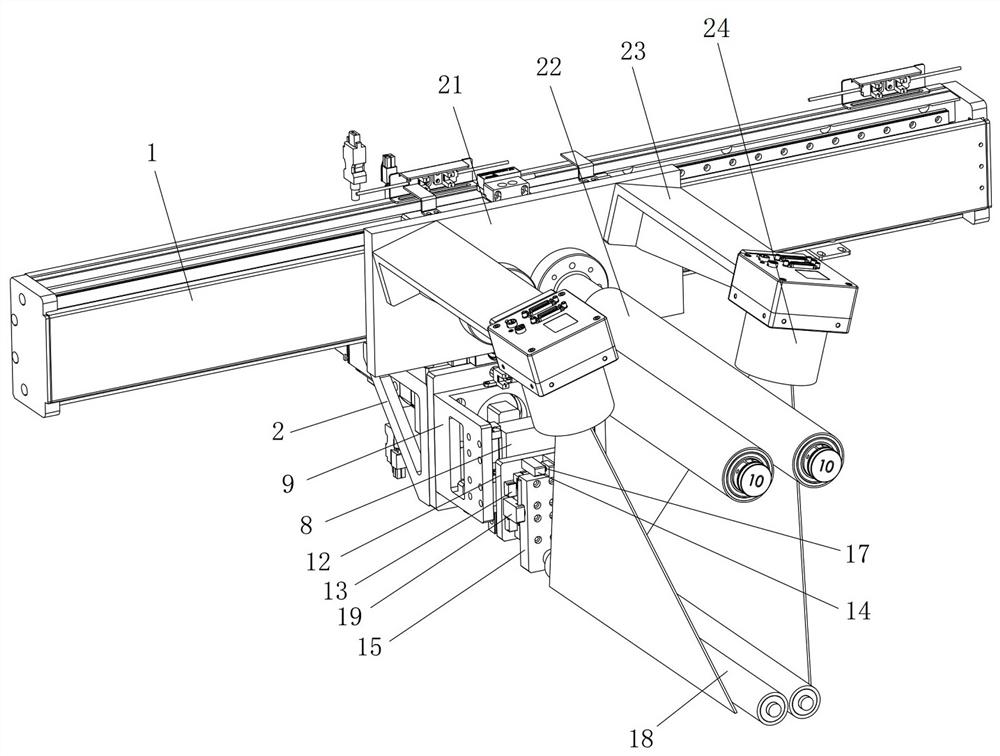

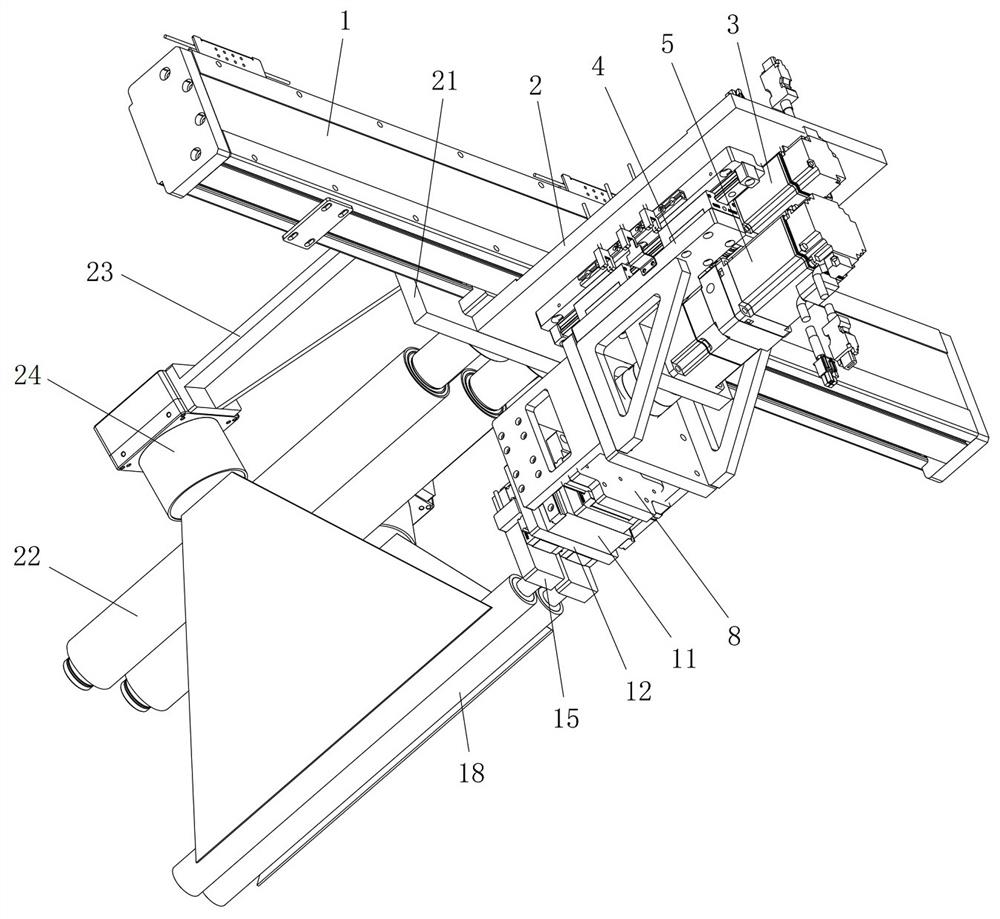

[0037] The present invention will be further described below in conjunction with accompanying drawing:

[0038] Such as Figure 1 to Figure 10 As shown, the technical solution adopted by the present invention is as follows: a laminated diaphragm covering device, including a linear module 1, a film covering mechanism and a film guiding mechanism, wherein the linear module 1 is horizontally arranged below the diaphragm unwinding mechanism; The above-mentioned film-guiding mechanism is arranged on the side wall of the linear module 1, and the film-guiding mechanism forms a film-guiding gap, and the diaphragm exported by the diaphragm unwinding mechanism passes through the film-guiding gap vertically downward; the above-mentioned film covering mechanism is slidably connected to the linear The bottom of the module 1 is connected to the output end of the linear module 1, and is driven by the linear module to move linearly back and forth in the horizontal direction; the laminating me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com