Conductive slurry for battery pole piece, battery pole piece and battery

A technology of conductive paste and battery pole piece, which is applied in the direction of battery electrodes, lead-acid battery electrodes, non-aqueous electrolyte battery electrodes, etc. It can solve the problems of easy aggregation, stacking and even precipitation of conductive paste, and achieve the effect of easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

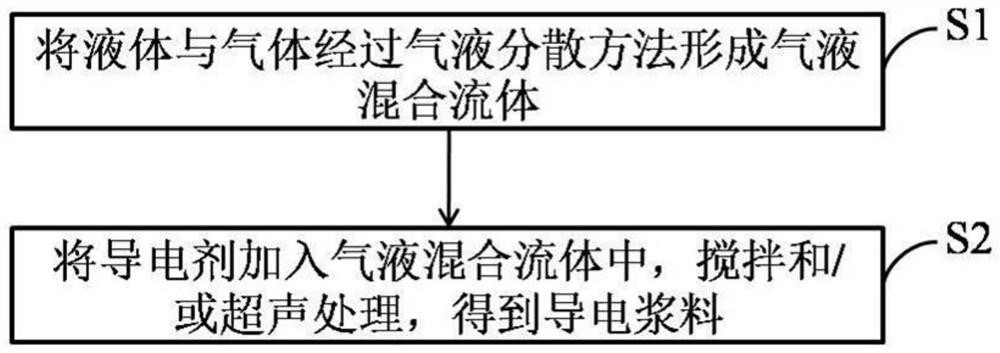

[0030] This embodiment provides a preparation method of conductive paste, the preparation steps are as follows: figure 1 As shown, including steps S1 and S2:

[0031] S1: The liquid and the gas are dispersed through the gas-liquid dispersion method to form a gas-liquid mixed fluid;

[0032] S2: adding a conductive agent into the gas-liquid mixed fluid, stirring and / or, after ultrasonic treatment, to obtain a conductive paste.

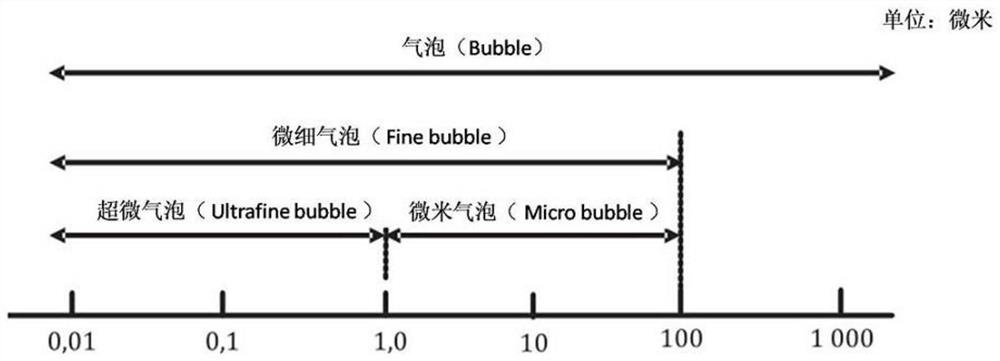

[0033] Wherein, the conductive agent includes graphene and / or carbon nanotube; the liquid includes water, N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF), ethanol, isopropanol (IPA), butyl One of ketone (MEK) or toluene; the obtained gas-liquid mixed fluid contains fine bubbles, the particle size of the fine bubbles is less than 100 μm, and the concentration of the fine bubbles is greater than 10 6 pcs / ml; the type of gas in the fine bubbles includes one or more of air, oxygen, nitrogen, argon, hydrogen, helium or ozone.

[0034] The following...

Embodiment 2

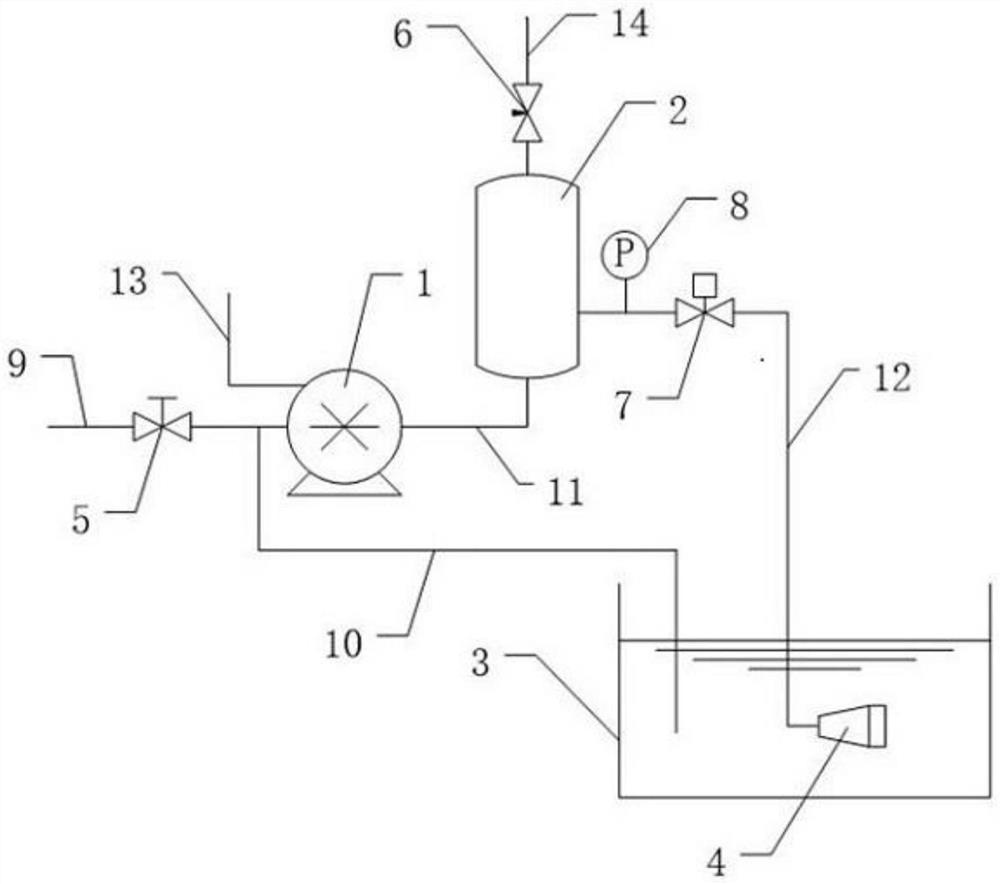

[0036] This embodiment provides a conductive paste whose components are composed of graphene, fine air bubbles and water. The type of gas in the fine bubbles is air. Its preparation method comprises step 1) and step 2):

[0037] Step 1) forming a gas-liquid mixed fluid by air and water through a gas-liquid dispersion method;

[0038] Step 2) adding a certain mass of conductive agent graphene into the 1L gas-liquid mixed fluid obtained in step 1), stirring and ultrasonic treatment to obtain a conductive paste.

[0039] Wherein, the mass range of the added graphene is between 5g and 86g, and the mass fraction of the conductive agent is approximately between 0.5wt.% and 8wt.% of the obtained conductive paste. Preferably, the amount of graphene added is between 30g and 50g, so that the mass fraction of the conductive agent in the conductive paste is about 3wt.% to 5wt.%. In this concentration range, the conductive paste exhibits better viscosity.

Embodiment 3

[0041] This embodiment provides a conductive paste whose components are composed of graphene, carbon nanotubes, fine air bubbles and water. The type of gas in the fine bubbles is air. Its preparation method comprises step 1) and step 2):

[0042] Step 1) forming a gas-liquid mixed fluid by air and water through a gas-liquid dispersion method;

[0043] Step 2) adding a certain mass of conductive agent (graphene and carbon nanotubes) into the 1L gas-liquid mixed fluid obtained in step 1), and stirring to obtain a conductive paste.

[0044]Wherein, the mass range of the conductive agent (graphene and carbon nanotube) is between 5g and 86g, and the mass ratio of graphene and carbon nanotube is between 1:10 and 1:0.1. Preferably, the conductive agent (of graphene and carbon nanotubes) is added in a mass of 30 to 50 g, and the mass ratio of graphene and carbon nanotubes is between 1:1 and 1:0.5, and the conductive paste in this range exhibits better viscosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com