Water-cooled furnace bottom electrode and masonry method

A water-cooled furnace bottom and electrode technology, applied in the field of smelting, can solve problems such as damage to furnace bottom refractories, environmental pollution, burn-through damage, etc., and achieve the effect of good protection effect and high overall safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

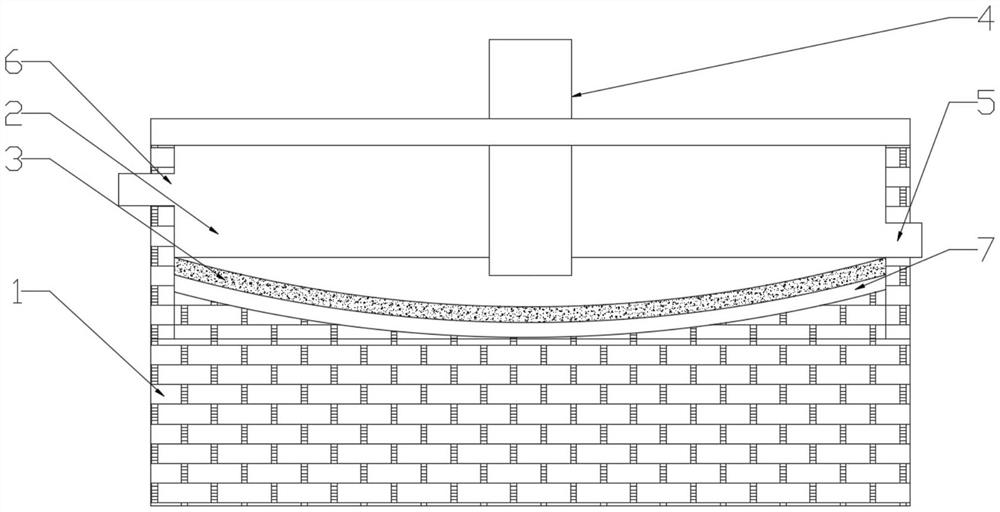

[0020] A water-cooled furnace bottom electrode, comprising a furnace base made of silicon-magnesium refractory bricks 1, a furnace body 2 is arranged on the furnace base, the upper end of the furnace base is in the shape of a downwardly concave arc, and the furnace base A silicon-magnesium-type high-temperature-resistant protective layer 3 is laid on the top, and an electrode 4 is provided in the furnace body 2. A discharge port 5 is provided at the lower end of one side of the furnace body 2, and a discharge port 5 is provided at the lower end of the other side of the furnace body 2. A slag outlet 6, and a cooling pipe layer 7 is provided on the furnace base.

[0021] The height of the discharge port 5 is lower than that of the slag discharge port 6 .

[0022] The cooling pipes in the cooling pipe layer 7 are copper pipes.

[0023] A water-cooled furnace bottom electrode and a masonry method, comprising the following steps:

[0024] Step 1: According to the size of the furn...

Embodiment 2

[0031] A water-cooled furnace bottom electrode, comprising a furnace base made of silicon-magnesium refractory bricks 1, a furnace body 2 is arranged on the furnace base, the upper end of the furnace base is in the shape of a downwardly concave arc, and the furnace base A silicon-magnesium-type high-temperature-resistant protective layer 3 is laid on the top, and an electrode 4 is provided in the furnace body 2. A discharge port 5 is provided at the lower end of one side of the furnace body 2, and a discharge port 5 is provided at the lower end of the other side of the furnace body 2. A slag outlet 6, and a cooling pipe layer 7 is provided on the furnace base.

[0032] The height of the discharge port 5 is lower than that of the slag discharge port 6 .

[0033] The cooling pipes in the cooling pipe layer 7 are copper pipes.

[0034] A water-cooled furnace bottom electrode and a masonry method, comprising the following steps:

[0035] Step 1: According to the size of the furn...

Embodiment 3

[0042] A water-cooled furnace bottom electrode, comprising a furnace base made of silicon-magnesium refractory bricks 1, a furnace body 2 is arranged on the furnace base, the upper end of the furnace base is in the shape of a downwardly concave arc, and the furnace base A silicon-magnesium-type high-temperature-resistant protective layer 3 is laid on the top, and an electrode 4 is provided in the furnace body 2. A discharge port 5 is provided at the lower end of one side of the furnace body 2, and a discharge port 5 is provided at the lower end of the other side of the furnace body 2. A slag outlet 6, and a cooling pipe layer 7 is provided on the furnace base.

[0043] The height of the discharge port 5 is lower than that of the slag discharge port 6 .

[0044] The cooling pipes in the cooling pipe layer 7 are copper pipes.

[0045] A water-cooled furnace bottom electrode and a masonry method, comprising the following steps:

[0046] Step 1: According to the size of the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com