MXenes compound catalyst as well as preparation method and application thereof

A technology of catalysts and composites, applied in the field of MXenes composite catalysts and their preparation, can solve the problems of uneven surface distribution, ineffective adjustment, weak interaction, etc., and achieve easy large-scale industrial preparation, low cost, and synthetic process conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

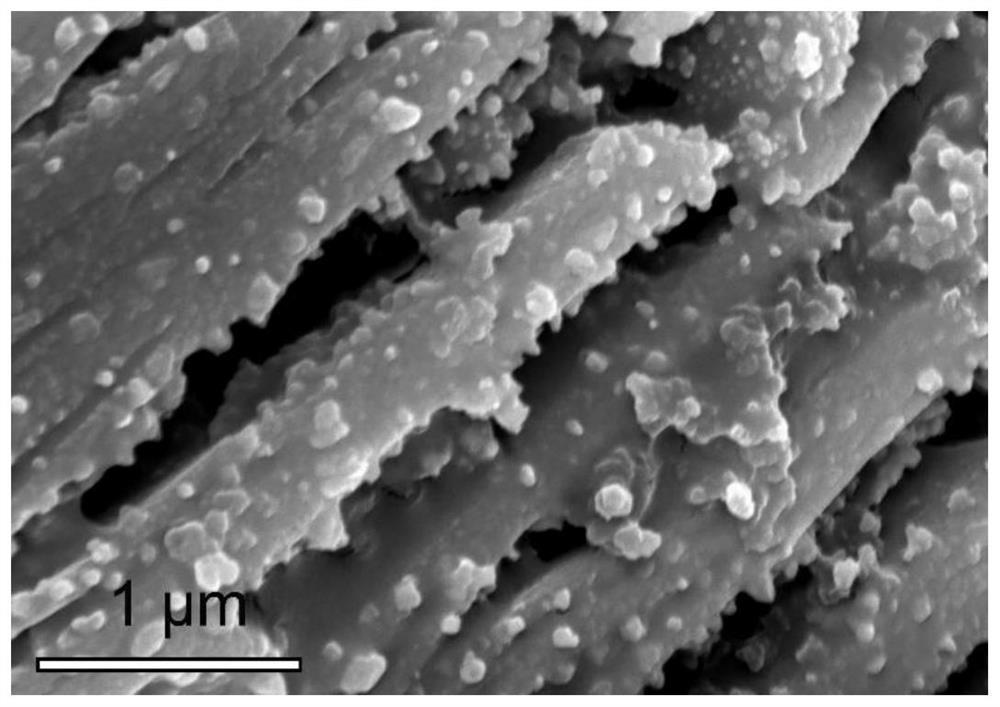

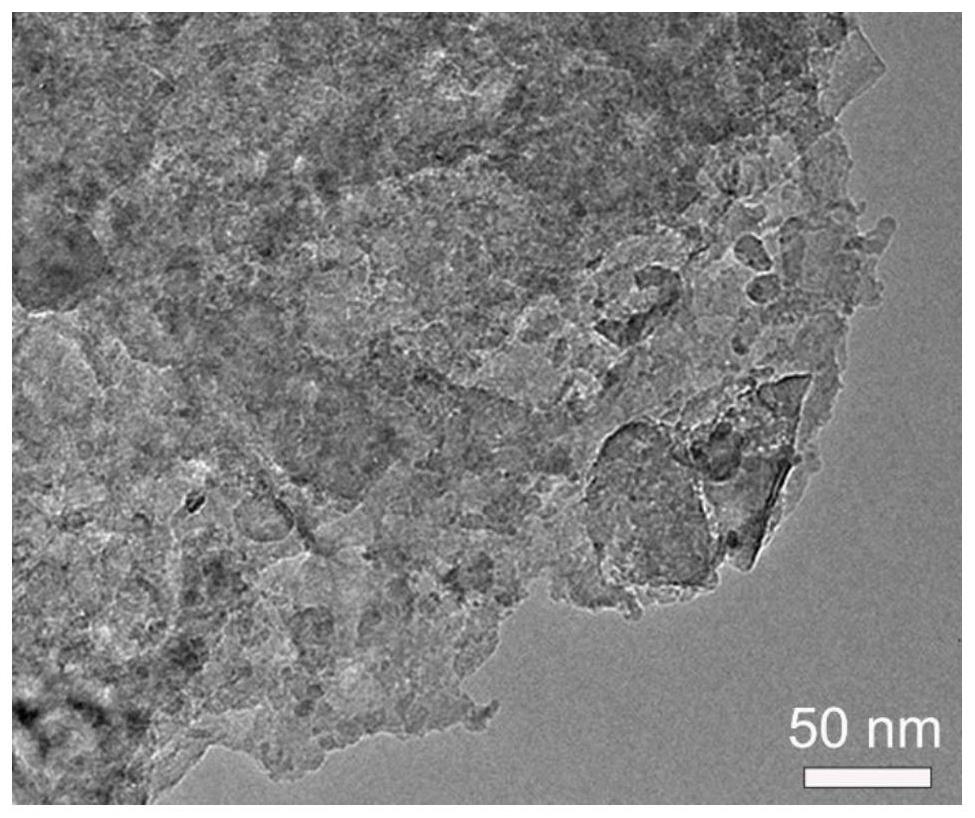

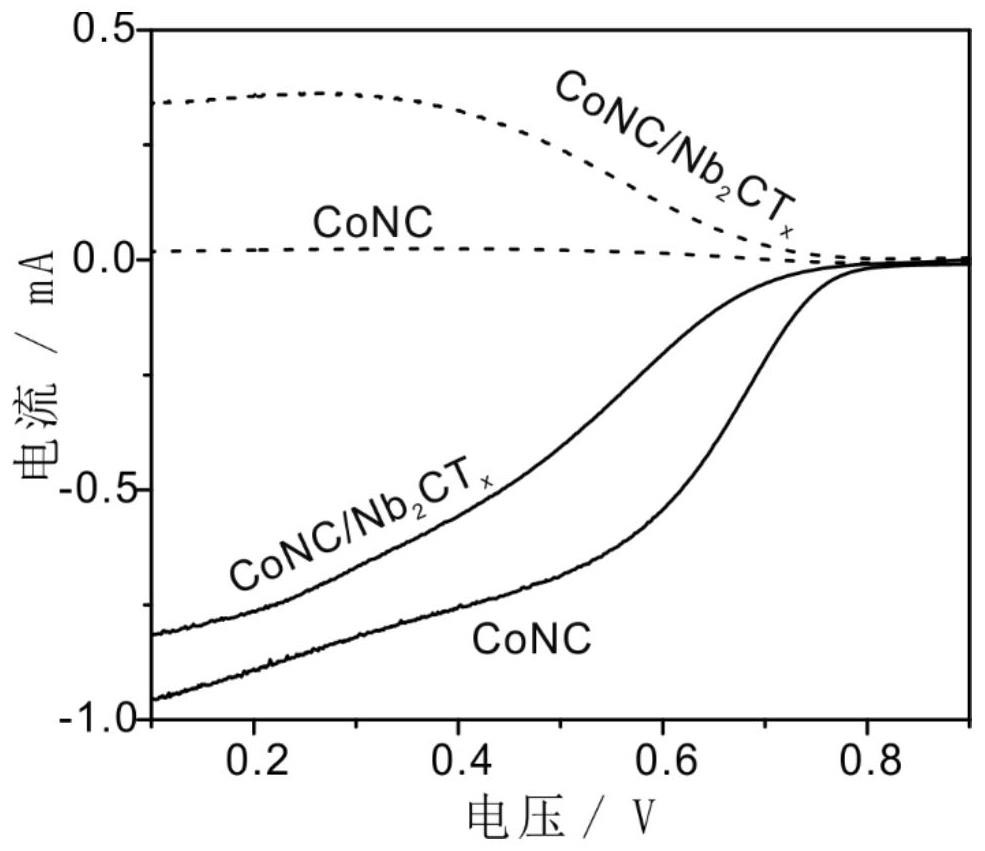

[0044] Example 1CONC / NB 2 CT x Preparation of materials

[0045] (1) Weigh 1G NB 2 ALC powder (Jilin Province, one-one technology Co., Ltd.) is placed in an HF solution of 20 ml of mass fraction of 40%, stirring the solution at room temperature, etching 48h, then washed, centrifuged 7 times, freeze drying 12h to obtain a layer Size NB 2 CT x MXENES substrate.

[0046] (2) Take 40mg NB 2 CT x Powder is added to 20 ml of anhydrous methanol in half an hour, according to 1 mmol of metal content, 0.182 g of CO (NO) 3 ) 2 Add to NB 2 CT x In the solution, stirring 24 h to obtain NB of adsorption CO 2 CT x Solution.

[0047] (3) Then, then the more than 20 ml of the dimethylimidazole solution of 0.4 mol / L / L was slowly added, and stirred for 4 h and then allowed to stand for 12h, centrifugally, and then dried in a vacuum drying tank at 60 ° C to obtain a precursor.

[0048] (4) Getting the dried precursor is calcined at 800 ° C under an argon atmosphere for 2 h to obtain a CONC / NB...

Embodiment 2

[0049] Example 2Conc / NB 2 CT x Preparation of materials

[0050] This example is substantially the same as in Example 1, and the difference is that NB 2 CT x Different, specifically take 20 mg powder NB in step (2) 2 CT x Add to 20 ml of anhydrous methanol.

Embodiment 3

[0051] Example 3CONC / NB 2 CT x Preparation of materials

[0052] This example is substantially the same as in Example 1, and the difference is that NB 2 CT x Different, specifically take 60 mg of powder NB in step (2) 2 CT x Add to 20 ml of anhydrous methanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com