Low-surface-energy organosilicone marine antifouling coating

A low surface energy, marine antifouling technology, used in marine antifouling coatings and underwater coatings, can solve the problems of promotion and application limitations, poor adhesion, low surface energy, etc., to achieve excellent adhesion performance, improve adhesion. The effect of knot strength and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

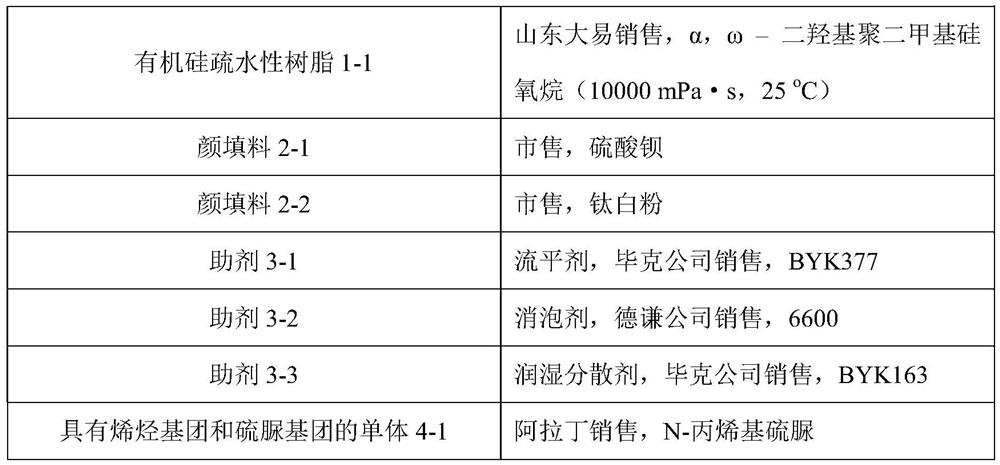

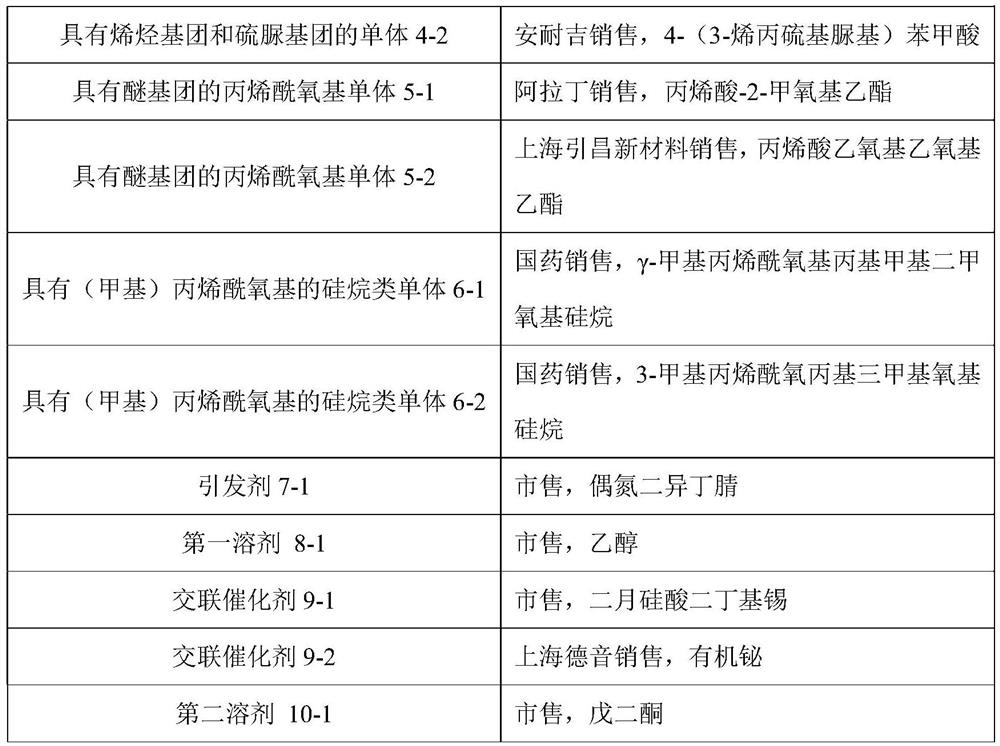

[0045] A method for preparing a low surface energy organosilicon marine antifouling coating, the marine antifouling coating comprises: (1) 10-20 parts of component A; (2) 4-8 parts of component B; 3) 1-2 parts of component C;

[0046] in,

[0047] The preparation steps of component A are as follows: add each composition into a dispersing mixer in parts by weight, disperse at 300 rpm for 30 minutes, and then take out the uniformly mixed component A and place it in a clean container.

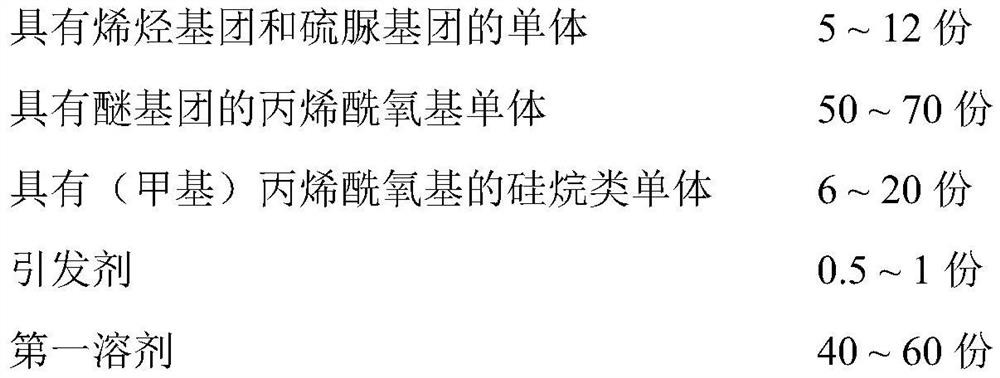

[0048]The preparation steps of component B are as follows: (1) In a light-proof environment, make monomers with olefin groups and thiourea groups, acryloyloxy monomers with ether groups, and (meth)acryloyloxy (2) At the same time, mix the initiator and the solvent at 300-500 rpm for 30-60 minutes by mechanical stirring; (3) Subsequently, the above two The mixture is introduced into the reaction kettle under the protection of nitrogen, and kept under the protection of nitrogen, the reaction is ca...

Embodiment 1】-【 Embodiment 4

[0059] The formula is shown in Table 2. The components A and C weigh the raw materials according to Table 2, and mix them evenly. The components B weigh the raw materials according to Table 2, and prepare according to the following steps:

[0060] (1) In a light-proof environment, pass monomers with olefin groups and thiourea groups, acryloyloxy monomers with ether groups, and silane monomers with (meth)acryloyloxy groups through Mechanical stirring at 300rpm for 60min;

[0061] (2) At the same time, the initiator and the first solvent were mixed for 30min at 500rpm by mechanical stirring;

[0062] (3) Subsequently, the two mixtures of step (1) and step (2) were introduced into the reactor under nitrogen protection, and kept under nitrogen protection, and reacted at 55°C for 5h;

[0063] (4) After the temperature of the reaction product drops to room temperature, component B can be obtained, and it should be taken out and stored away from light.

[0064] Table 2

[0065] ...

Embodiment 5

[0068] Prescription is identical with embodiment 1, and wherein B component is prepared according to the following steps:

[0069] (1) In a light-proof environment, pass monomers with olefin groups and thiourea groups, acryloyloxy monomers with ether groups, and silane monomers with (meth)acryloyloxy groups through Mechanical stirring at 500rpm for 30min;

[0070] (2) Simultaneously, the initiator and the first solvent were mixed for 40min at 400rpm by mechanical stirring;

[0071] (3) Subsequently, the two mixtures of step (1) and step (2) were introduced into the reactor under nitrogen protection, and kept under nitrogen protection, and reacted at 50°C for 4h;

[0072] (4) After the temperature of the reaction product drops to room temperature, component B can be obtained, and it should be taken out and stored away from light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com