Lubricating oil for methanol fuel engine and preparation method thereof

A technology of methanol fuel and lubricating oil, which is applied in the field of lubricating oil, can solve problems such as lack of lubricating oil composition, achieve good metal anti-wear performance and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

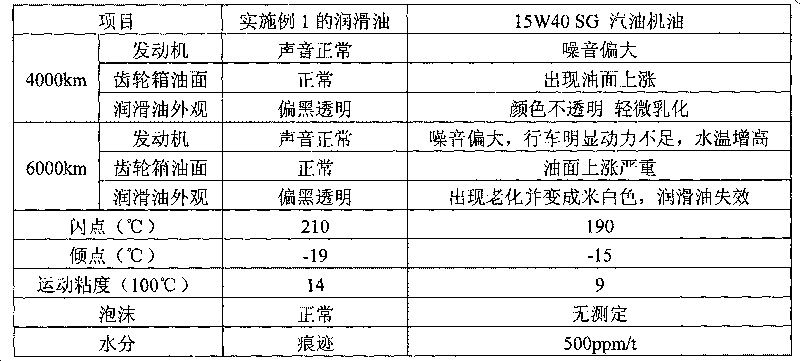

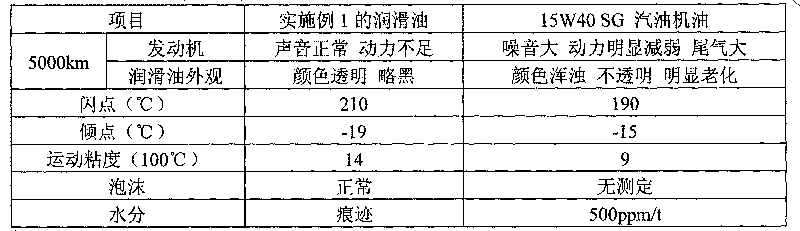

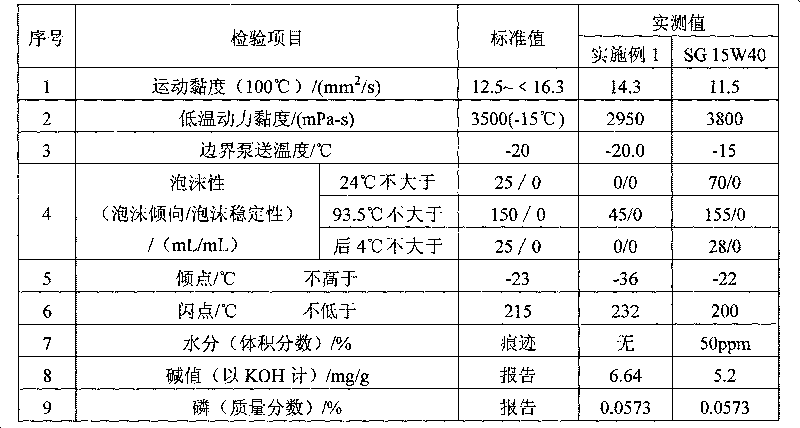

Examples

Embodiment 1

[0067] A lubricating oil applied to an engine fueled by M85 methanol gasoline, which consists of the following components:

[0068] Synthetic calcium sulfonate 4.8kg Defoamer 120ppm

[0069] Monoalkenylsuccinimide 3.6kg Barium Petroleum Sulfonate 0.3kg

[0070] Long-chain primary alkyl zinc dithiophosphate 1.5kg Dewaxed secondary hydrogenated base oil 76.05kg

[0071] Octyldiphenylamine 0.6kg T1001 0.15kg

[0072] Polymethacrylate 8kg Tricresyl Phosphate 1.9kg

[0073] Benzotriazole fatty acid amine salt 2.8kg T803B 0.3kg

[0074] Prepare described lubricating oil according to the following method:

[0075] 1) Pour 76.05kg of dewaxed secondary hydrogenated base oil into a heating and stirring device, heat to 75°C, and stir at constant temperature for 1 hour;

[0076] 2) Add 8kg of polymethacrylate to the substance obtained in step 1), heat to 80°C, and stir at constant temperature for 30 minutes;

[0077] 3) The temperature of the mixture obtained in step 2) is lowered t...

Embodiment 2

[0081] A lubricating oil applied to an engine fueled by M100 methanol gasoline, which consists of the following components:

[0082] Synthetic Magnesium Sulfonate 2.2kg Polyacrylate 120ppm

[0083] Dienylsuccinimide 3.6kg Benzotriazole 0.3kg

[0084] Long-chain primary alkyl zinc dithiophosphate 0.6kg Dewaxed secondary hydrogenated base oil 82.3kg

[0085] Octyldiphenylamine 0.3kg T1001 0.1kg

[0086] Polymethacrylate 6.2kg Di-n-butyl phosphite 1.2kg

[0087] Benzotriazole fatty acid ammonium salt 2.8kg T803C 0.4kg

[0088] Prepare described lubricating oil according to the following method:

[0089] 1) Pour 82.3kg of dewaxed secondary hydrogenated base oil into a heating and stirring device, heat to 75°C, and stir at constant temperature for 1 hour;

[0090] 2) Add 6.2kg of polymethacrylate to the substance obtained in step 1), heat to 80°C, and stir at constant temperature for 30 minutes;

[0091] 3) The temperature of the mixture obtained in step 2) was lowered to 75°...

Embodiment 3

[0095] A lubricating oil applied to an engine fueled by M100 methanol gasoline, which consists of the following components:

[0096] Synthetic Magnesium Sulfonate 5.0kg Dienylsuccinimide 6.6kg

[0097] Long chain primary alkyl zinc dithiophosphate 1.6kg Benzotriazole 0.5kg

[0098] Amyldiphenylamine 0.8kg Dewaxed secondary hydrogenated base oil 64.95kg

[0099] Polymethacrylate 10.2kg T1001 0.25kg

[0100] Benzotriazole fatty acid amine salt 5.6kg Di-n-butyl phosphite 3.8kg

[0101] Polyacrylate 120ppm T803B 0.7kg

[0102] Prepare described lubricating oil according to the following method:

[0103] 1) Pour 64.95kg of dewaxed secondary hydrogenated base oil into a heating and stirring device, heat to 75°C, and stir at constant temperature for 1 hour;

[0104] 2) Add 10.2kg of polymethacrylate to the substance obtained in step 1), heat to 80°C, and stir at constant temperature for 30 minutes;

[0105] 3) Lower the temperature of the mixture obtained in step 2) to 75°C, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com