High-hardness and scratch-resistant interior wall finish coating and preparation method thereof

A scratch-resistant, high-hardness technology, which is applied in the field of scratch-resistant interior wall finish coatings and high hardness, to achieve the effect of widening possible application scenarios, good paint film performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

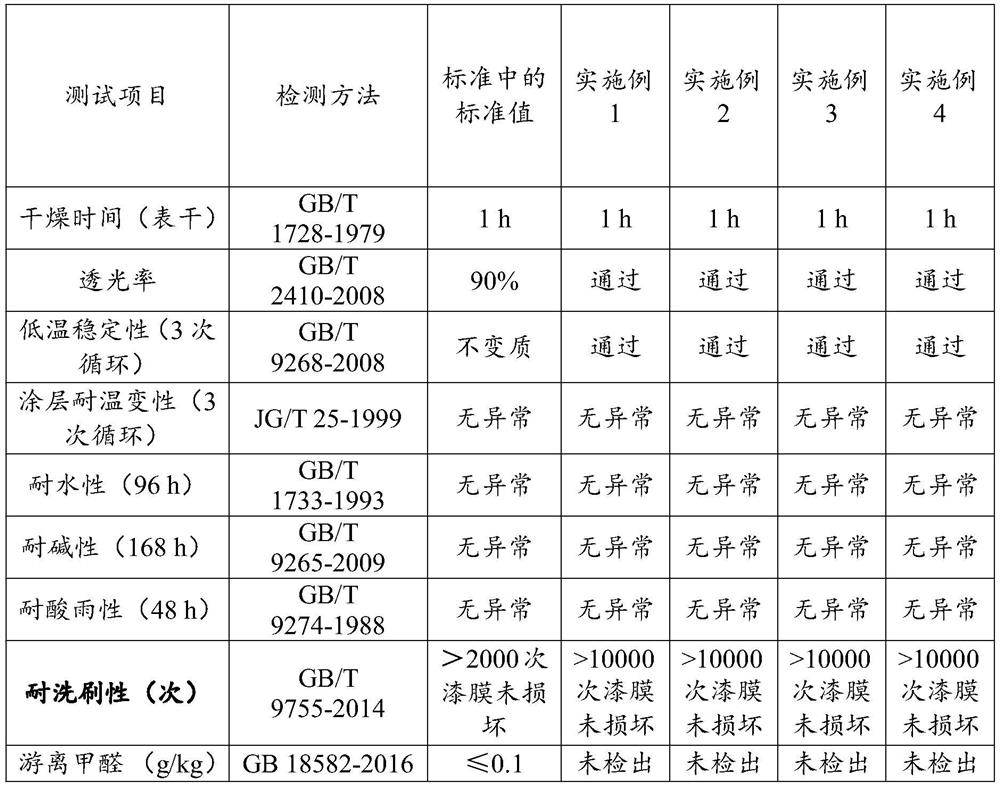

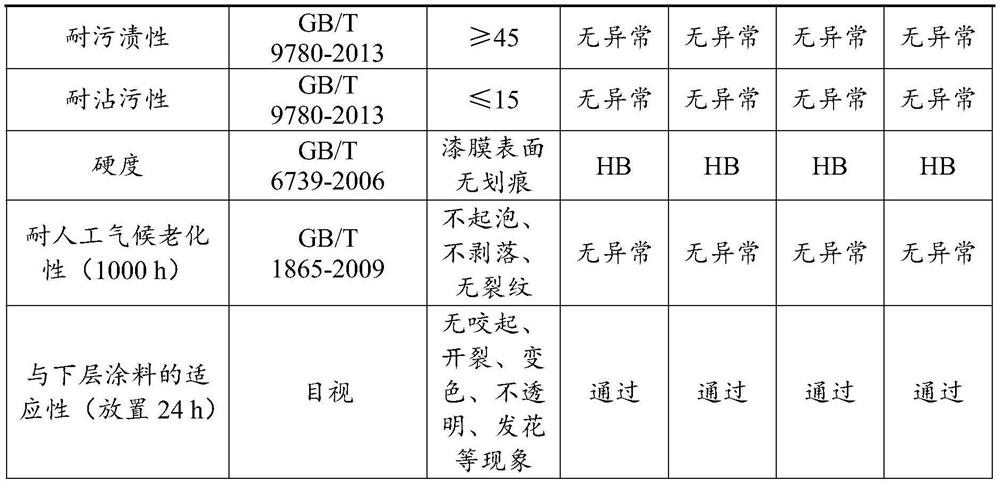

Examples

Embodiment 1

[0043] A high-hardness, scratch-resistant interior wall finish paint according to the present invention is mainly prepared from the following components according to the following mass and part ratios:

[0044] 30 parts of water

[0045] 0.3 parts of pH regulator

[0046] 0.5 parts of water-based dispersant

[0047] 0.5 parts of water-based wetting agent

[0048] 0.2 parts of water-based defoamer

[0049] wax powder 2 parts

[0050] Silica powder 5 parts

[0051] 3 parts kaolin

[0052] White carbon black 2 parts

[0053] 7 servings of mica flakes

[0054] 40 parts of lotion

[0055] Antifreeze 2 parts

[0056] Coalescing aid 2 parts

[0057] Preservative 0.5 part

[0058] 5 parts of water-based thickener.

[0059] The emulsion is an acrylic emulsion.

[0060] The preparation method of the high-hardness, scratch-resistant interior wall finish coating mainly includes the following steps carried out in sequence:

[0061] (1) Start the mixer, adjust the speed to 600rp...

Embodiment 2

[0067] A high-hardness, scratch-resistant interior wall finish paint according to the present invention is mainly prepared from the following components according to the following mass and part ratios:

[0068] 40 parts of water

[0069] 0.3 parts of pH regulator

[0070] 1.0 parts of water-based dispersant

[0071] 1.0 parts of water-based wetting agent

[0072] 0.3 parts of water-based defoamer

[0073] 5 parts wax powder

[0074] Silica powder 1 part

[0075] 1 part kaolin

[0076] White carbon black 3 parts

[0077] 3 servings of mica flakes

[0078] 35 parts of lotion

[0079] 3 parts of antifreeze

[0080] Coalescing aid 1.5 parts

[0081] Preservative 0.4 parts

[0082] 4 parts of water-based thickener.

[0083] The emulsion is an acrylic emulsion.

[0084] The preparation method of the high-hardness, scratch-resistant interior wall finish coating mainly includes the following steps carried out in sequence:

[0085] (1) Start the mixer, adjust the speed to...

Embodiment 3

[0091] A high-hardness, scratch-resistant interior wall finish paint according to the present invention is mainly prepared from the following components according to the following mass and part ratios:

[0092] 40 parts of water

[0093] 0.2 parts of pH regulator

[0094] 0.5 parts of water-based dispersant

[0095] 0.5 parts of water-based wetting agent

[0096] 0.3 parts of water-based defoamer

[0097] 7 parts of wax powder

[0098] Silica powder 2 parts

[0099] 2 parts kaolin

[0100] White carbon black 1 part

[0101] 2 pieces of mica flakes

[0102] 35 parts of lotion

[0103] Antifreeze 4 parts

[0104] Coalescing aid 2 parts

[0105] Preservative 0.5 parts

[0106] 3 parts of water-based thickener.

[0107] The emulsion is an acrylic emulsion.

[0108] The preparation method of the high-hardness, scratch-resistant interior wall finish coating mainly includes the following steps carried out in sequence:

[0109] (1) Start the mixer, adjust the speed to 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com