Method for purifying biodiesel by-product crude glycerine

A technology of biodiesel and purification method, which is applied in the field of purification of biodiesel by-product crude glycerol, can solve the problems of affecting the distillation efficiency of crude glycerin, unsatisfactory separation effect, and long processing time, so as to shorten the purification time, reduce the processing cost, The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

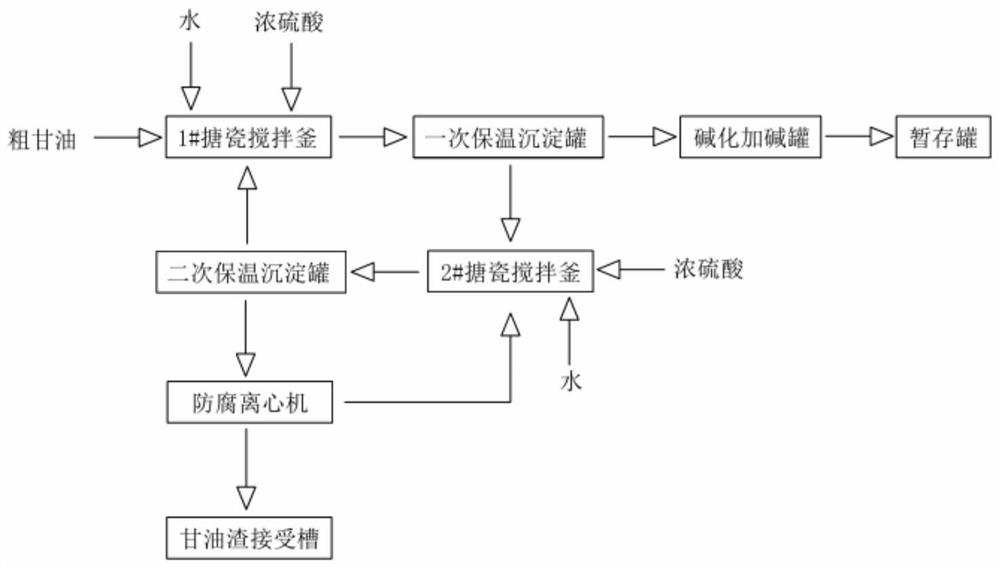

[0023] The purification method of biodiesel by-product crude glycerin of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] figure 1 , figure 2 Shown, the purification method operating steps of the biodiesel by-product crude glycerol of the present invention are as follows:

[0025] The first step: the preparation of the acidic mixed solution of ferric sulfate-tannin extract that the mass ratio concentration is 10%: with 9.2kg solid ferric sulfate powder, 0.8kg tannin extract solid powder, be the dilute sulfuric acid heating of 0.01mol / L with 90kg concentration Stir to dissolve after reaching 50-60°C, and adjust to PH<2 with concentrated sulfuric acid to prevent hydrolysis failure of the ferric sulfate-tannin extract solution;

[0026] The second step: biodiesel by-product crude glycerin enters 10m through crude glycerin feed pipe 1 3 The primary enamel stirring kettle 5 is starte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com