On-line heating method and device for stainless steel pipe

A stainless steel tube and heating method technology, applied in induction heating device, electric heating device, induction heating and other directions, can solve the problem of large residual stress, and achieve the effect of improving material performance and quality, improving heating quality, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

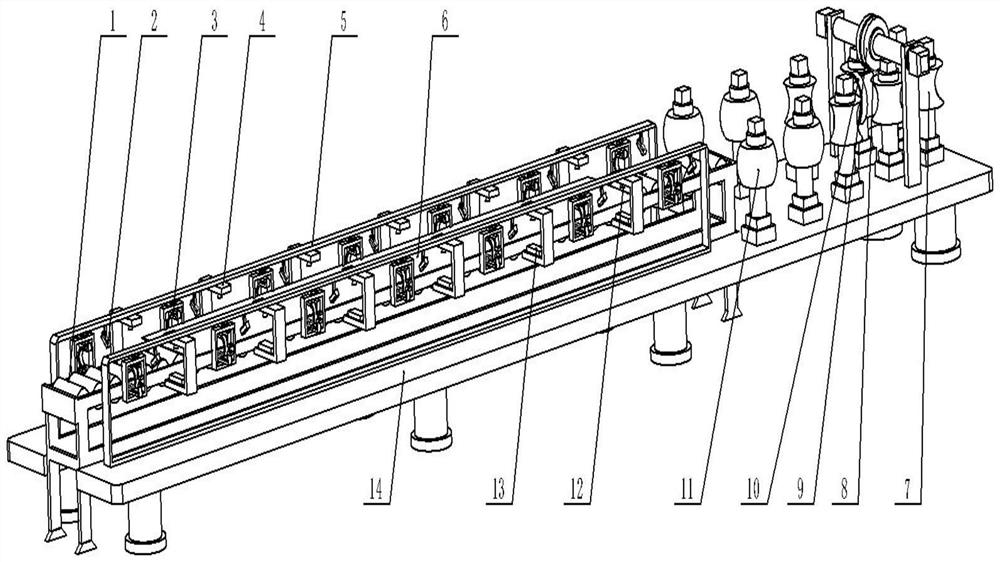

[0032] In order to detail the technical content, structural features, achieved objects and effects of the present invention, the following will be described in detail with reference to the accompanying drawings.

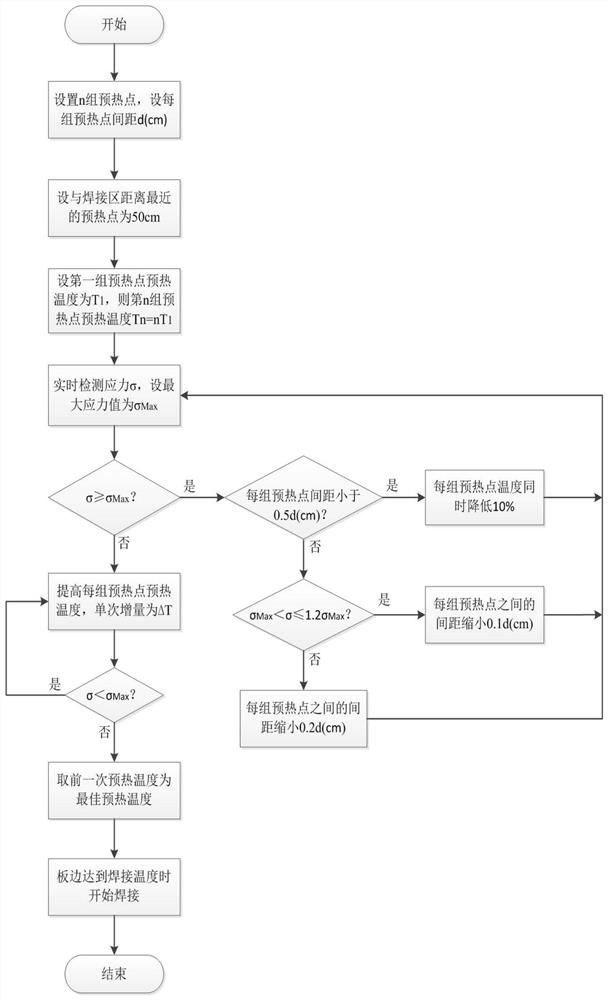

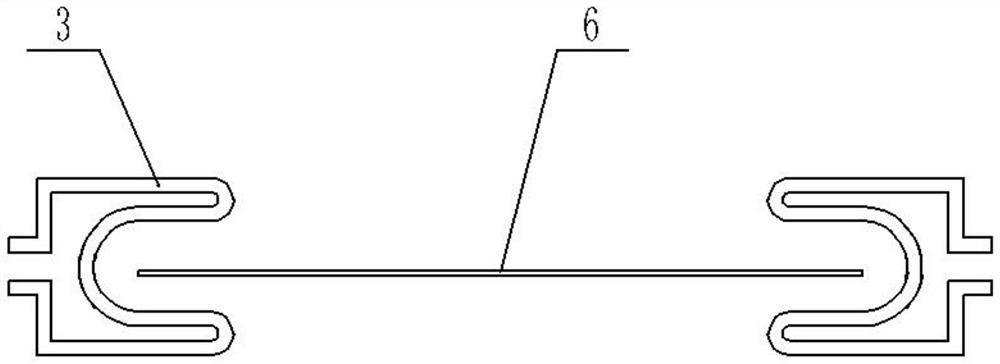

[0033] The on-line heating method for stainless steel pipes of the present invention is used to preheat both sides of the strip 6 through the induction heating coils 3 installed on the two sides of the frame 5 before the strip is crimped. The temperature sensor 2 and the X-ray stress detection device 4 on the side can monitor the heating condition of the strip 6 and the stress generated during the heating process in real time, and ensure that the stress value is within the allowable range by determining the optimal spacing between the induction heating coils 3. In this way, the temperature gradient caused by excessively high temperature during welding can be greatly reduced, so that the problem of excessive welding stress can be avoided, the material properties and qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com