Non-uniform punching device capable of fixing round hard alloy material

A cemented carbide and punching device technology, applied in positioning devices, feeding devices, automatic control devices, etc., can solve problems such as inability to fix heat-conducting materials, uneven punching, etc., to facilitate subsequent processing, improve product quality, and improve product quality. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

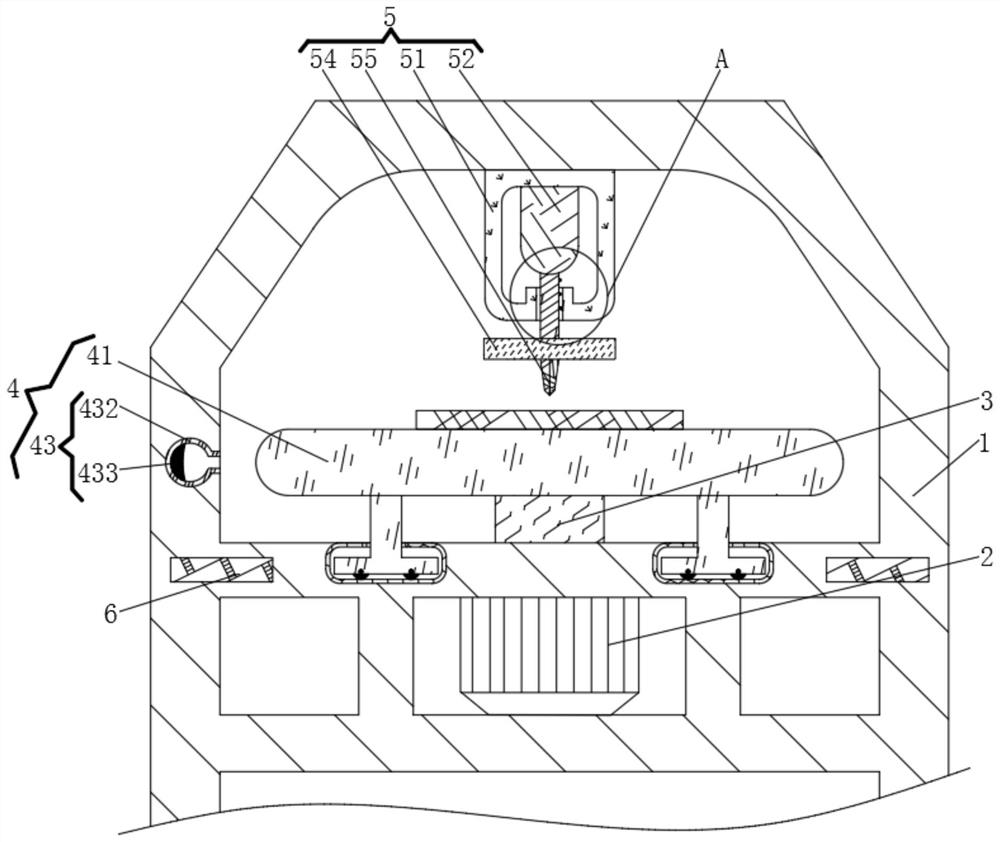

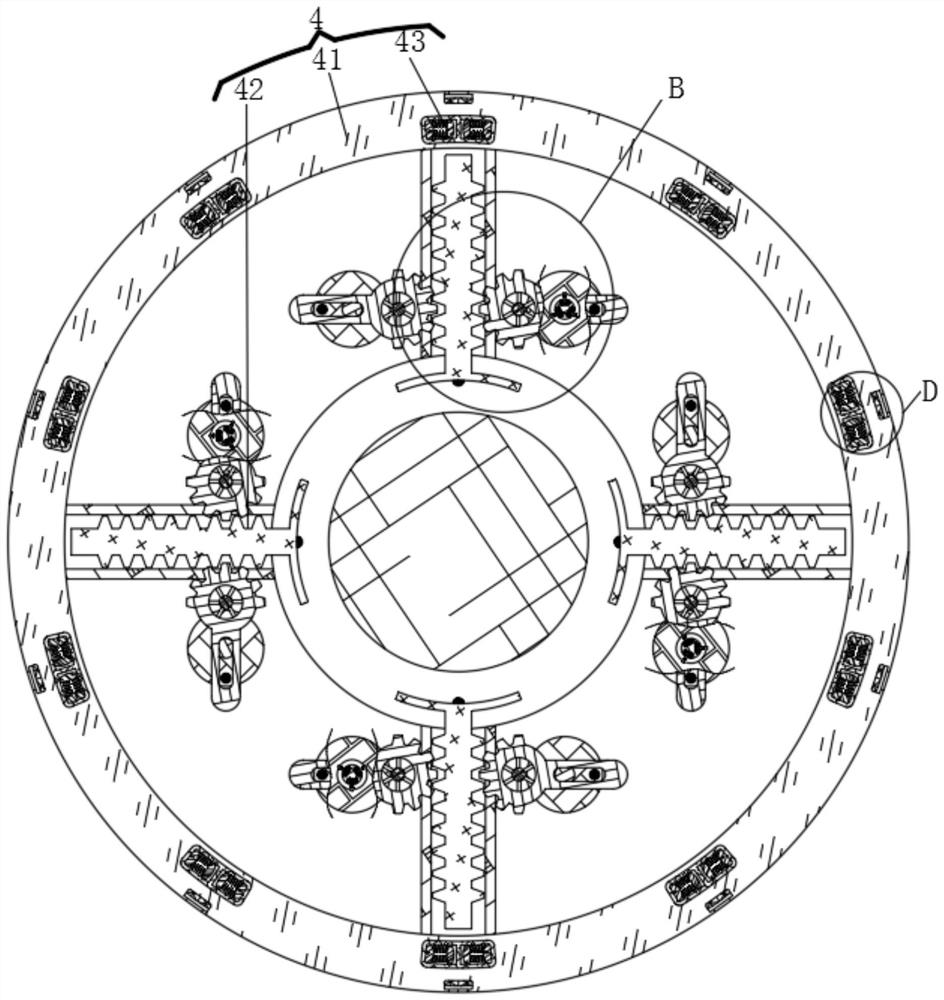

[0032] see figure 1 , 3 , 4, 5, 6, a non-uniform punching device capable of fixing round hard alloy materials, including a casing 1, the inside of the casing 1 is fixedly connected with a motor-2, and the outside of the motor-2 is fixedly connected with a rotating shaft 3 The outside of the rotating shaft 3 is movably connected with a fixed rotation mechanism 4 , the fixed rotation mechanism 4 includes a support plate 41 , and the inside of the support plate 41 is movably connected with a fixed assembly 42 .

[0033] The fixed assembly 42 includes a fixed shaft 421, a support shell 422, an electromagnet 423, a push rod 424, a support spring 425, a rotating disk 426, a gear rotating rod 427, a rack slide bar 428, and a slide rail 429. The fixed shaft 421 is fixedly connected to the support Inside the plate 41, the support shell 422 is fixedly connected to the inside of the fixed shaft 421, the electromagnet one 423 is fixedly connected to the inside of the support shell 422, t...

Embodiment 2

[0038] see Figure 1-2 , a non-uniform punching device capable of fixing round hard alloy materials, comprising a casing 1, the inside of the casing 1 is fixedly connected with a motor-2, the outside of the motor-2 is fixedly connected with a rotating shaft 3, and the outside of the rotating shaft 3 The movable connection has the fixed rotating mechanism 4 that the workpiece to be processed is fixed.

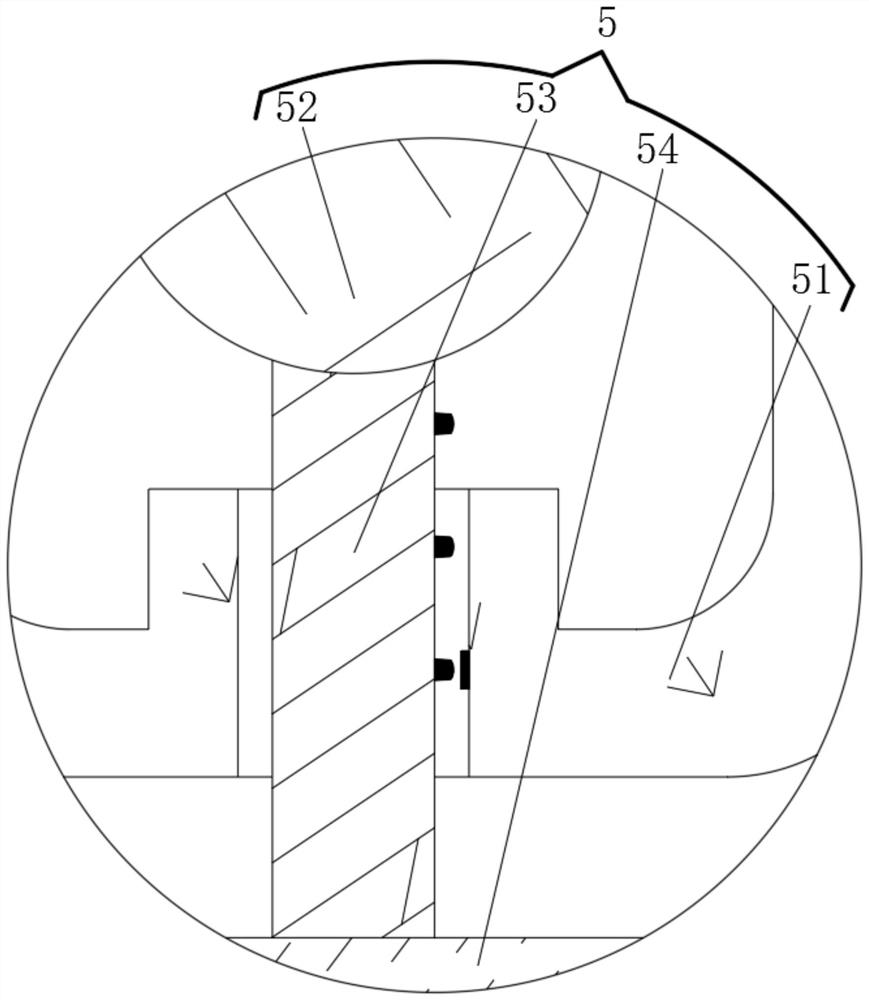

[0039] The inside of the shell 1 is movably connected with a fixed-depth punching mechanism 5, which includes a connecting shell 51, a cylinder 52, a push rod 53, a support frame 54, and a puncher 55. The connecting shell 51 is fixedly connected to the bottom of the shell 1. Inside, the cylinder 52 is fixedly connected to the inside of the connecting shell 51, the push rod 53 is slidably connected to the outside of the cylinder 52, the support frame 54 is fixedly connected to the outside of the push rod 53, and the puncher 55 is movably connected to the outside of the support fr...

Embodiment 3

[0042] see Figure 1-6 , a non-uniform punching device capable of fixing round hard alloy materials, comprising a casing 1, the inside of the casing 1 is fixedly connected with a motor-2, the outside of the motor-2 is fixedly connected with a rotating shaft 3, and the outside of the rotating shaft 3 A fixed rotation mechanism 4 is movably connected, and the fixed rotation mechanism 4 includes a support plate 41 , and a fixed component 42 is movably connected to the inside of the support plate 41 .

[0043] The fixed assembly 42 includes a fixed shaft 421, a support shell 422, an electromagnet 423, a push rod 424, a support spring 425, a rotating disk 426, a gear rotating rod 427, a rack slide bar 428, and a slide rail 429. The fixed shaft 421 is fixedly connected to the support Inside the plate 41, the support shell 422 is fixedly connected to the inside of the fixed shaft 421, the electromagnet one 423 is fixedly connected to the inside of the support shell 422, the push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com