Method for producing IMP and GMP through anti-solvent cooling crystallization based on solvent spray oscillation

A cooling crystallization and anti-solvent technology, which is applied in the field of food seasoning, can solve the problems of cumbersome operation, energy consumption, anti-solvent waste, and limited effect, and achieve the effect of short time consumption, small temperature fluctuation, and good dissolution strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

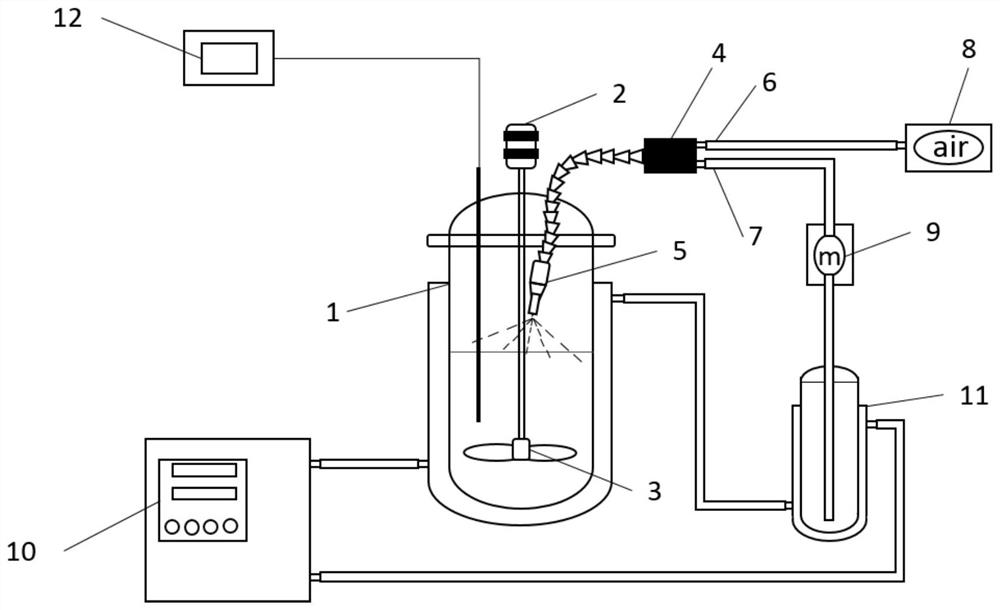

Method used

Image

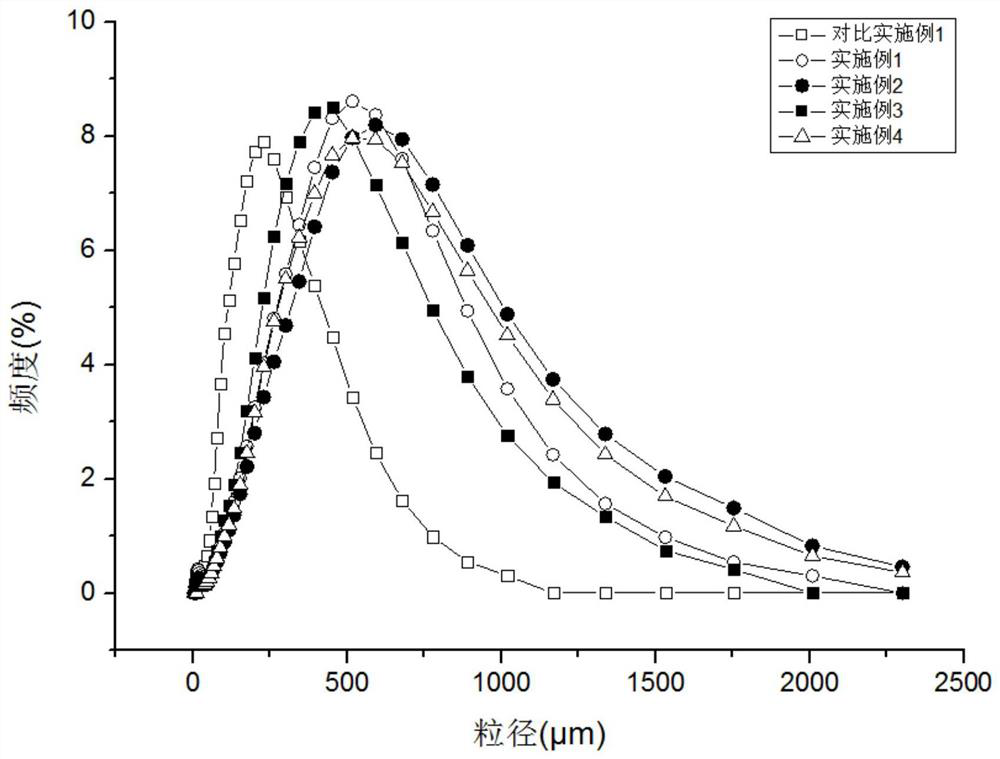

Examples

Embodiment 1

[0039] A method for producing IMP+GMP based on solvent spray vibration and anti-solvent cooling crystallization, comprising the steps of:

[0040] Step 1: Weigh 30g each of IMP and GMP with an analytical balance, and measure 200mL of water with a graduated cylinder. The two are added to a 500mL crystallization kettle 1, and the water bath is heated to 65°C by controlling the high and low temperature constant temperature tank 10. Stirring at a stirring speed of 180rpm makes The solute is fully dissolved and the pH is adjusted to 7.9. Then keep 80mL of water in the jacketed thermos cup 11 connected in series with the crystallizer water bath. Add 100 mL of anti-solvent 90% ethanol at a rate of 4 mL / min, add 2.8 g of IMP+GMP seed crystals (the mass ratio of IMP and GMP seed crystals is 1:1), and the seed crystals are prepared by mixing and recrystallizing IMP and GMP. After growing the crystal for 20 minutes, start the program to cool down at 5°C / h, 8°C / h, 12°C / h, 14°C / h, 16°C / h,...

Embodiment 2

[0045] Step 1: Weigh 30g each of IMP and GMP with an analytical balance, and measure 200mL of water with a graduated cylinder. The two are added to a 500mL crystallization kettle 1, and the water bath is heated to 65°C by controlling the high and low temperature constant temperature tank 10. Stirring at a stirring speed of 180rpm makes The solute is fully dissolved and the pH is adjusted to 7.8. Then 105mL of water is kept warm in the jacketed thermos cup 11 connected in series with the crystallizer water bath. Add 100 mL of anti-solvent 90% ethanol at a rate of 6 mL / min, add 3.0 g of IMP+GMP seed crystals (the mass ratio of IMP and GMP seed crystals is 1:2), and the seed crystals are prepared by mixing and recrystallizing IMP and GMP, After growing the crystal for 20 minutes, start the program to cool down at 4°C / h, 6°C / h, 8°C / h, 10°C / h, 12°C / h, 14°C / h, and drop to the end in 6 hours.

[0046] Step 2: When the temperature is lowered to 55°C, adjust the stirring speed of the ...

Embodiment 3

[0050] Step 1: Weigh 30g each of IMP and GMP with an analytical balance, and measure 220mL of water with a graduated cylinder. The two are added to the crystallization kettle 1, and the temperature of the high and low temperature constant temperature bath 10 is raised to 63°C and stirred at a stirring speed of 200rpm to make the solute Dissolve fully and adjust the pH to 7.6. Then keep 100mL of water in the jacketed thermos cup 11 connected in series with the crystallizer water bath. Add 110 mL of anti-solvent 90% ethanol at an addition rate of 6 mL / min, add 4.0 g of IMP+GMP seed crystals (the mass ratio of IMP and GMP seed crystals is 2:1), and the seed crystals are prepared by mixing and recrystallizing IMP and GMP. After 20 minutes, start the program to cool down at 5°C / h, 7°C / h, 10°C / h, 14°C / h, 15°C / h, and drop to the end in 5 hours.

[0051] Step 2: When the temperature drops to 53°C, adjust the stirring speed of the agitator 2 to 60rpm, the particles will naturally sett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com