Material tracking data processing system and method in iron and steel enterprise management and control system

A technology for tracking data and managing and controlling systems, applied in the field of information, can solve the problems of long CPU time, slow processing speed, frequent waiting for disk IO, etc., to achieve the effect of simplifying program structure, fast reading and writing speed, and ensuring data consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

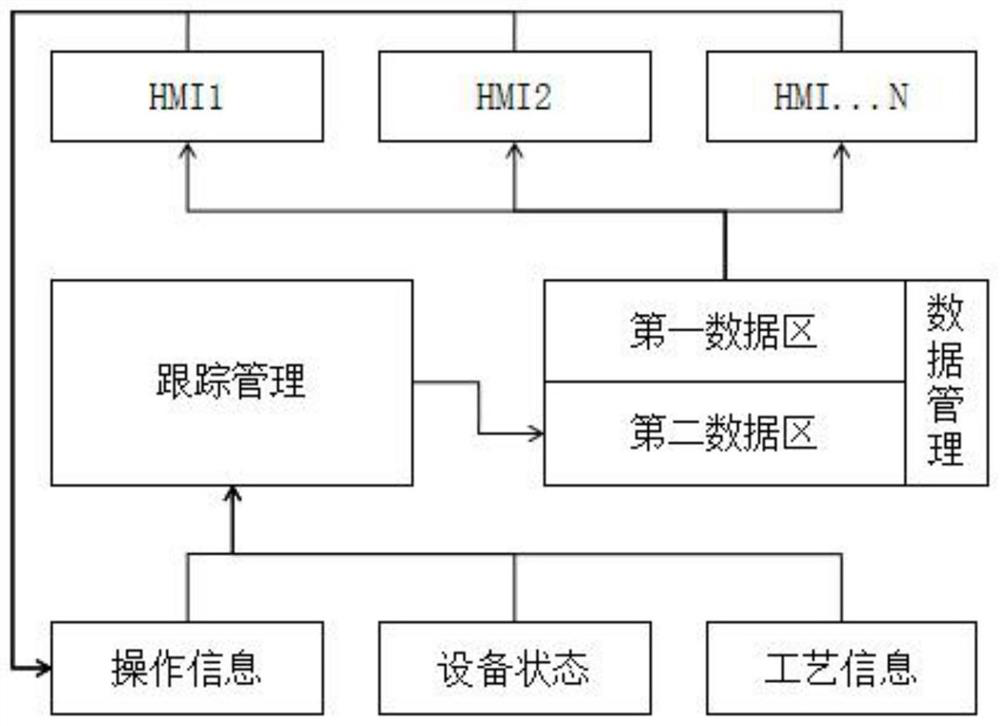

[0046] see figure 1 , the present invention provides a material tracking data processing system in the iron and steel enterprise management and control system, including a tracking management module, a data management module, a first data area for use as a cache and having high-speed read and write functions, and a data area for persistent data The second data area is stored in the second data area, and the second data area is used as data persistence to ensure that the data is not lost; the tracking management module is used to receive material tracking data, and the data management module is used to coordinate management of the first data area and the second data area The second data area completes the process of reading and writing data.

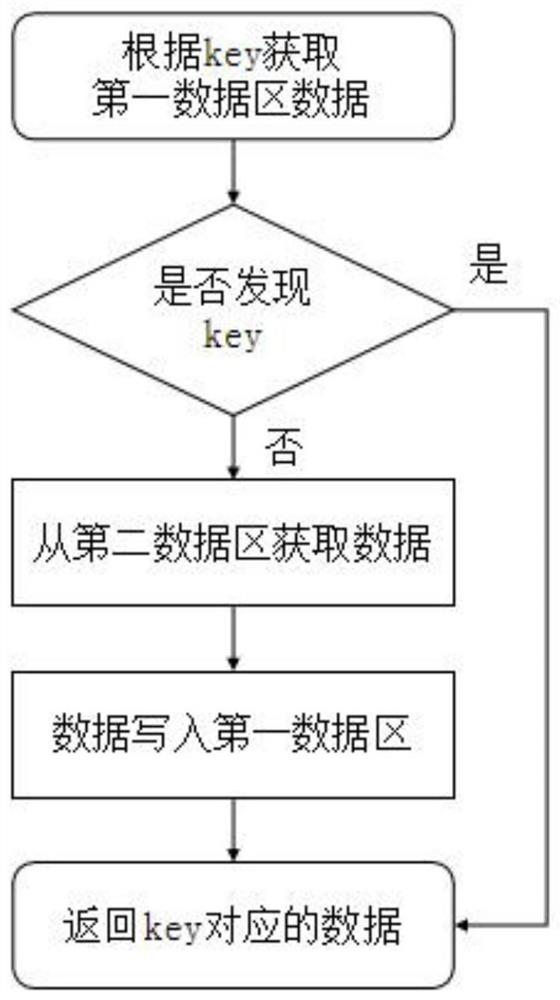

[0047] Further, the data management module is used to start the data read process on demand, read data from the first data area or the second data area and write the data in the second data area into the first data area as required, and ...

Embodiment 2

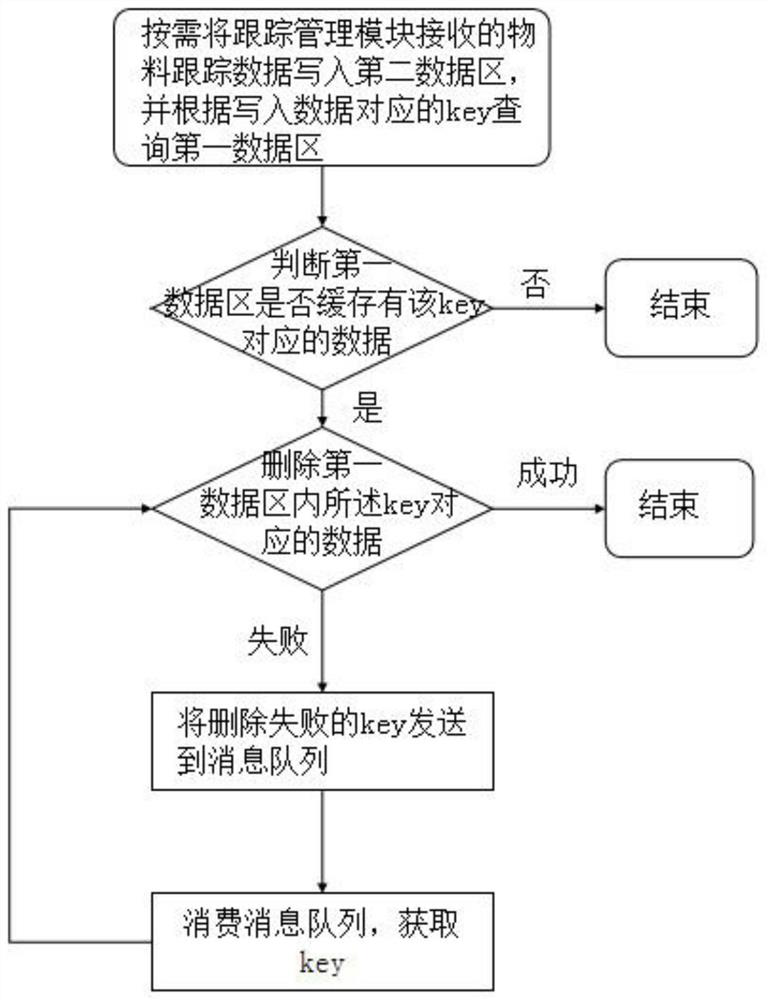

[0056] see Figure 4 , the first data area selects Redis storage, the second data area selects MySQL database, and the data management module is used to start the data writing (update) process on demand, specifically including: the MySQL database opens binlog, and the data management module will track The material tracking data received by the management module is written into MySQL data, and the MySQL database writes the change information of the data table data into the binlog log. The data management module triggers the deletion of the data corresponding to the key in the first data area by subscribing to the binlog. If the deletion is successful, the process End; if the deletion fails, send the failed key to the message queue; consume the message queue, obtain the key, and re-execute the delete cache operation until the data corresponding to the specified key in the first data area is successfully deleted. Key is agreed within the program and is used to uniquely identify d...

Embodiment 3

[0058] see figure 1 and figure 2 , the embodiment of the present invention also discloses a material tracking data processing method in the iron and steel enterprise management and control system, including the following steps:

[0059] The tracking management module receives the material tracking data. When the tracking management module receives the material tracking data, the data management module starts the data writing process, and persists the material tracking data received by the tracking management module into the second data area;

[0060] When the data management module receives the request for data acquisition, it starts the data readout process, which specifically includes the following steps: the data management module queries the first data area according to the key contained in the request, and judges whether the first data area has a cache corresponding to the key. data, if so, obtain the data corresponding to the key from the first data area, and return th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com