Copper etching solution for Array process thick film technology in FP industry

A thick film process and copper etching technology, which is applied in the field of metal etching, can solve problems such as unstable chemical solution, safety accidents, and increased metal film thickness, and achieve the effects of controllable etching efficiency, long service life, and high safety

Pending Publication Date: 2022-02-01

SUZHOU BOYANG CHEM

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the thickness of the metal film layer in the thick film process is greatly increased, the amount of etching required is also greatly increased

The copper etching solution that can be used in the thick film process often has insufficient etching life, resulting in instability of the solution and easy to cause safety accidents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

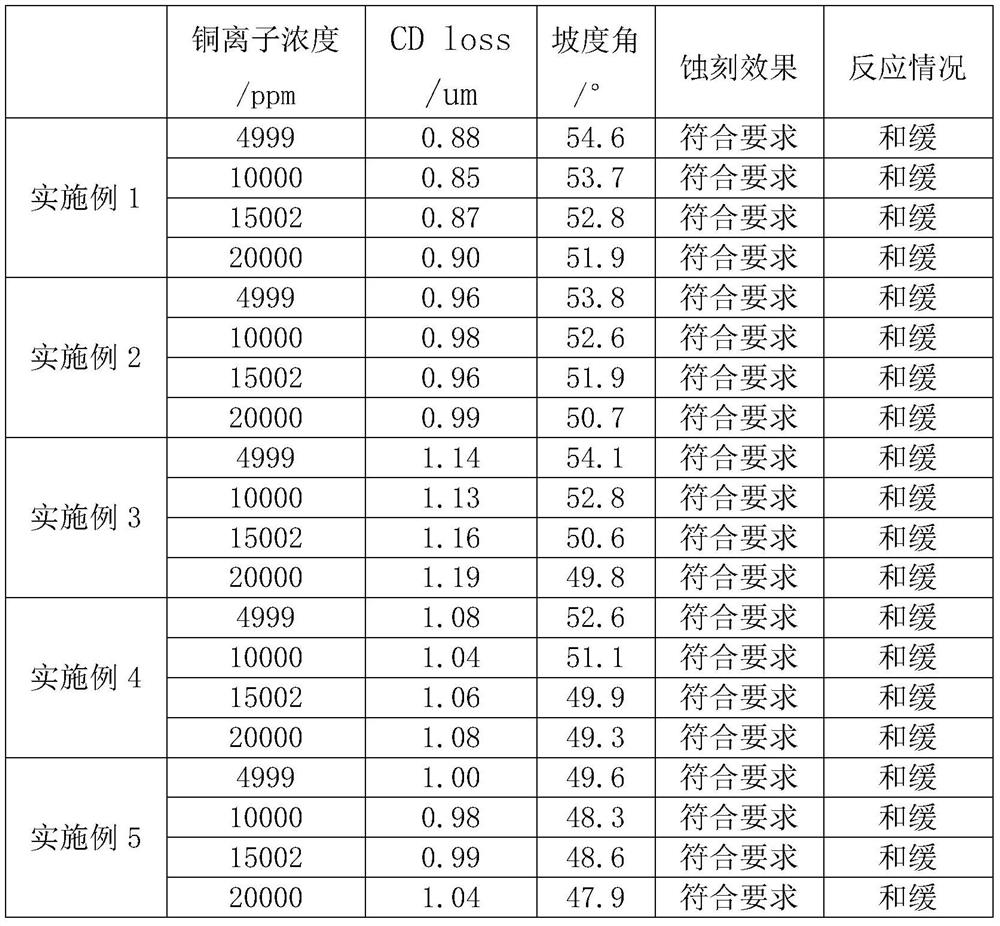

Effect test

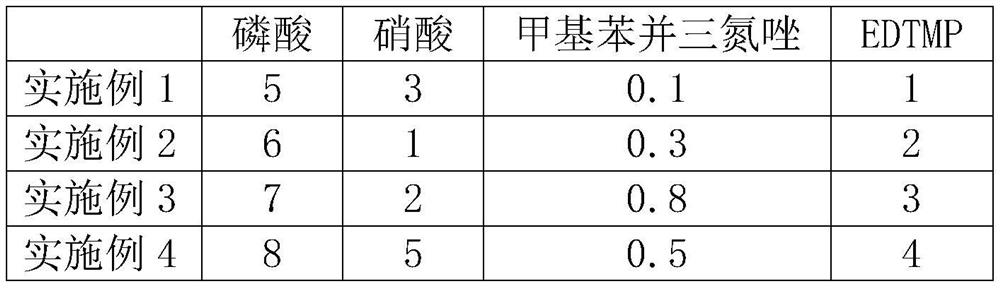

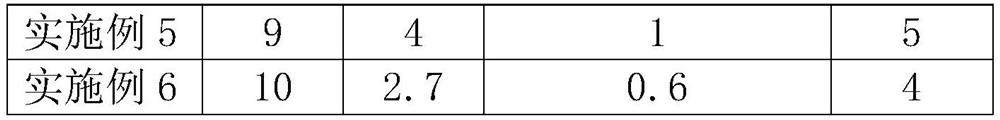

Embodiment 1-5

[0016] According to the formula of Table 1, the copper etching solution for the Array process thick film process of FP industry prepared by mixing and preparing the embodiment 1-5:

[0017] Table 1: Unit: wt%

[0018]

[0019]

[0020] Note: The part less than 100wt% in the content is supplemented by deionized water.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of metal etching, and particularly relates to a copper etching solution for an Array process thick film process in the FP industry, which comprises the following components in percentage by mass: 5-10 percent of phosphoric acid, 1-5 percent of strong oxidizing acid, 0.1-1 percent of methylbenzotriazole, 1-5 percent of a chelating agent and the balance of deionized water. According to the invention, hydrogen peroxide is not contained in the formula, the stability is good, the safety is high, the etching efficiency is controllable, the service life is long, and the requirement of thick film process copper process etching can be met.

Description

technical field [0001] The invention relates to the technical field of metal etching, in particular to a copper etching solution used in the thick film process of the Array process in the FP industry. Background technique [0002] Thick film circuit refers to an integrated circuit composed of a passive network fabricated on the same substrate using array film technology (screen printing, sintering and electroplating, etc.) and assembled with discrete semiconductor devices, monolithic integrated circuits or micro components. A thick film is generally considered a film with a thickness of several micrometers to tens of micrometers. Thick-film hybrid integrated circuits are characterized by more flexible design, simple process, and low cost, and are especially suitable for multi-variety and small-batch production. In terms of electrical performance, it can withstand higher voltage, greater power and greater current. Thick film technology is widely used in automotive, consumer...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F1/18

CPCC23F1/18

Inventor 陈浩李华平王润杰

Owner SUZHOU BOYANG CHEM

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com