A photoresist composition comprising polyparahydroxystyrene polymer and acrylate copolymer

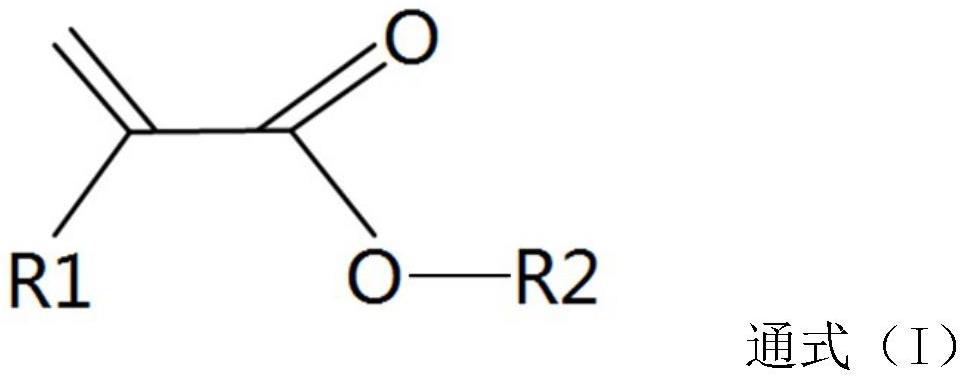

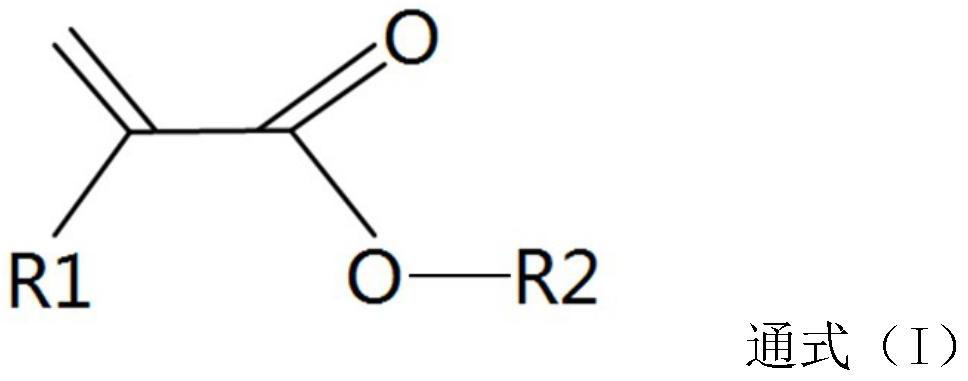

A technology of hydroxystyrene and adamantanol methacrylate, which is applied in the field of photoresist, can solve problems such as thick film cracking, and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] This embodiment relates to the synthesis of poly(p-hydroxystyrene) polymers, and its synthetic route is as follows:

[0076] Under nitrogen protection, 97.3g of 4-acetoxystyrene (ASM), 20.8g of styrene (ST) and 25.6g of tert-butyl acrylate (TBA) were added successively to a 500ml four-necked flask, and then added 3.3 g of initiator azobisisobutyronitrile (AIBN), tetrahydrofuran as a solvent, and then react at 65-70° C. for 18 hours. After removing the protective group from the reaction product, a terpolymer of 4-hydroxystyrene-styrene-butyl acrylate is obtained, the weight average molecular weight Mw is 29.7K, and the molecular weight distribution Mw / Mn is 2.3.

Embodiment 2

[0078] This embodiment relates to the synthesis of tetrapolymers comprising acrylate comonomers, and its synthetic route is as follows: In this embodiment, 2-ethyl-2-adamantanol methacrylate (CAS accession number: 209982-56 -9), 2-carbonyl-tetrahydrofuran-3-hydroxy-methacrylate (α-methacryloyloxy-γ-butyrolactone, CAS accession number: 195000-66-9), cedaryl alcohol methacrylate (CAS accession number: 132603 -01-1), the molar ratio of 3-hydroxy-1-adamantanol methacrylate (CAS accession number: 115372-36-6) is 40:25:10:25.

[0079] In a 500ml four-necked flask, sequentially add monomer 46.1g of 2-ethyl-2-adamantanol methacrylate, 19.8g of 2-carbonyl-tetrahydrofuran-3-hydroxy-methacrylate, 13.5g of cedar Alcohol methacrylate, 27.4g of 3-hydroxy-1-adamantanol acrylate, 1.52g of initiator AIBN and 200g of solvent 1,4-dioxane, completely dissolved at room temperature under the action of magnetic stirring Finally, under the protection of nitrogen, set the temperature of the oil bath ...

Embodiment 3

[0081] This example relates to the preparation of a photoresist composition using the 4-hydroxystyrene-styrene-butyl acrylate terpolymer according to Example 1 and the acrylate copolymer according to Example 2.

[0082] In a clean 250 ml polypropylene plastic bottle, add 9g of 4-hydroxystyrene-styrene-butyl acrylate terpolymer according to embodiment 1, 21g of acrylate tetrapolymer synthesized according to embodiment 2, 0.6 g of triphenylsulfonium perfluorobutylsulfonate, 0.04 g of trioctylamine, and 69.32 g of mixed solvent PGMEA / PGME (8:2). Then, fix the polypropylene plastic bottle including the above-mentioned materials on a mechanical vibrator, and vibrate at room temperature for 10-24 hours to fully dissolve the above-mentioned materials. Finally, it was filtered through a filter with a pore size of 0.2 micron to obtain the photoresist composition according to Example 3.

[0083] Photolithography experiment method and results: The photoresist composition prepared above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com