Method for efficiently degrading solid waste of polyurethane coating

A technology for polyurethane coating and solid waste, which is applied in the recycling field of waste polyurethane, can solve the problems of declining physical properties, abandonment, and short product chain length, and achieves the effect of ensuring high added value and reducing the content of amine substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The polyurethane paint waste to be degraded in this embodiment is collected from the spraying work surface, the cutting operation work surface and the floor of the operation room in the paint production workshop.

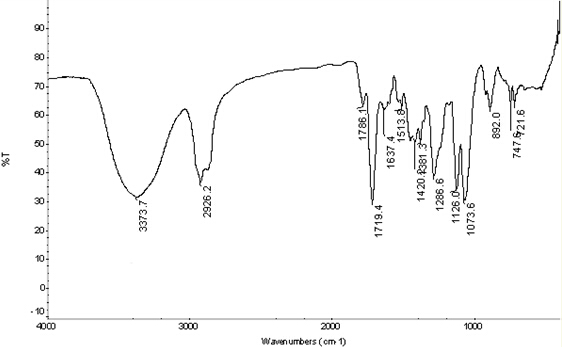

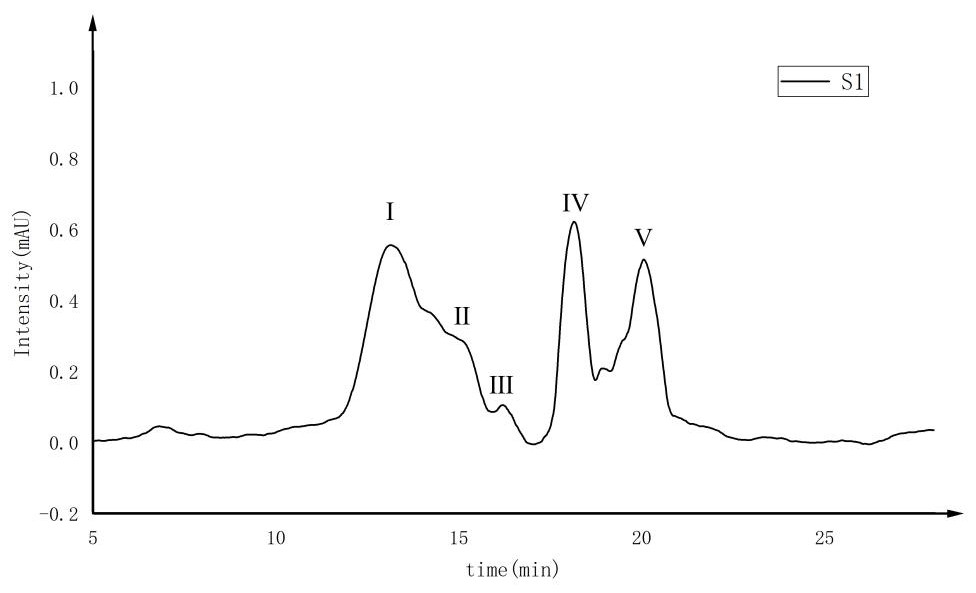

[0041]Mix 75g PUW (polyurethane paint waste) with 268.0ml (300g) diethylene glycol and 5.52ml (7g) stannous octoate to form a degradation system, add it to a 500ml three-necked flask, add a magnet for magnetic stirring, and install A spherical condenser with water as the condensing agent. Fit the thermowell and stopper to the oblique opening and seal with parafilm. After pumping air from the top of the condenser tube for 10 minutes, nitrogen gas was introduced, and the nitrogen gas was continuously fed after repeating the operation 3 times to ensure that the reaction was carried out under a nitrogen atmosphere. Place the device in an oil bath, start heating and stirring, start timing when the thermometer shows 180°C, stop heating and stirring after 3 hours, ...

Embodiment 2

[0043] The used polyurethane waste composition of this embodiment is with embodiment 1

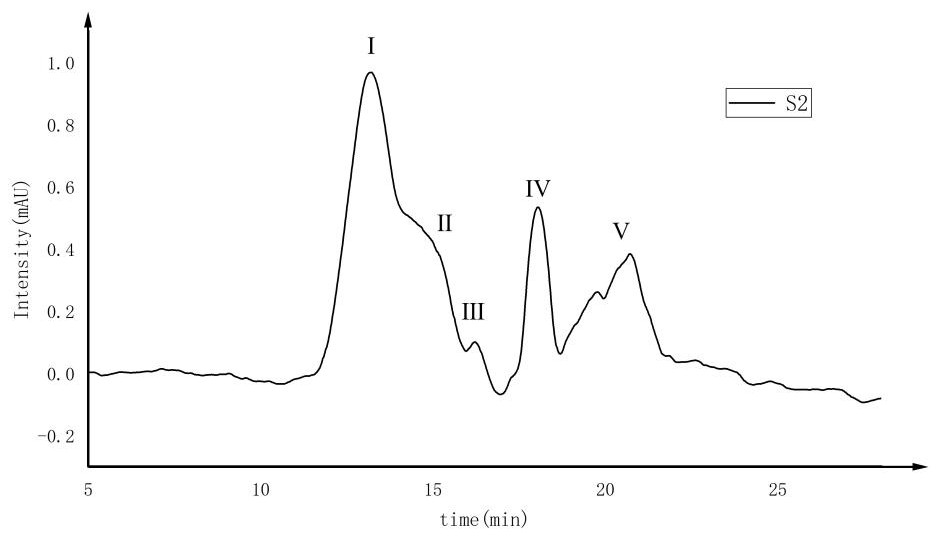

[0044] Mix 10g PUW (polyurethane paint waste) with 17.90ml (21.122g) diethylene glycol and 0.312ml (0.39g) stannous octoate to form a degradation system, add it to a 50ml three-necked flask, add a magnet for magnetic stirring, and put it on A spherical condenser tube with water as the condensing agent is installed at the port. Fit the thermowell and stopper to the oblique opening and seal with parafilm. After pumping air from the top of the condenser tube for 10 minutes, nitrogen gas was introduced, and the nitrogen gas was continuously fed after repeating the operation 3 times to ensure that the reaction was carried out under a nitrogen atmosphere. Place the device in an oil bath, start heating and stirring, start timing when the thermometer shows 180°C, stop heating and stirring after 2 hours, and let it cool naturally. After cooling, put the mixed product in a centrifuge tube, centrif...

Embodiment 3

[0046] The used polyurethane waste composition of this embodiment is with embodiment 1

[0047] Mix 5.0g PUW (polyurethane paint waste) with 17.90ml diethylene glycol and 0.260ml stannous octoate to form a degradation system, add it to a 50ml three-necked flask, add a magnet for magnetic stirring, and install water as a condensing agent on the top spherical condenser. Fit the thermowell and stopper to the oblique opening and seal with parafilm. After pumping air from the top of the condenser tube for 10 minutes, nitrogen gas was introduced, and the nitrogen gas was continuously fed after repeating the operation 3 times to ensure that the reaction was carried out under a nitrogen atmosphere. Place the device in an oil bath, start heating and stirring, start timing when the thermometer shows 180°C, stop heating and stirring after 2 hours, and let it cool naturally. After cooling, place the mixed product in a centrifuge tube, centrifuge at a high speed of 10,000 rpm for 8 min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com