Manufacturing method of large thin-wall special-shaped curved surface component

A special-shaped surface and manufacturing method technology, applied in the field of alloy product processing, can solve the problems of poor part profile accuracy, low production efficiency, uneven deformation, etc., and achieve improved forming precision, low production cost, and reduced profile distortion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

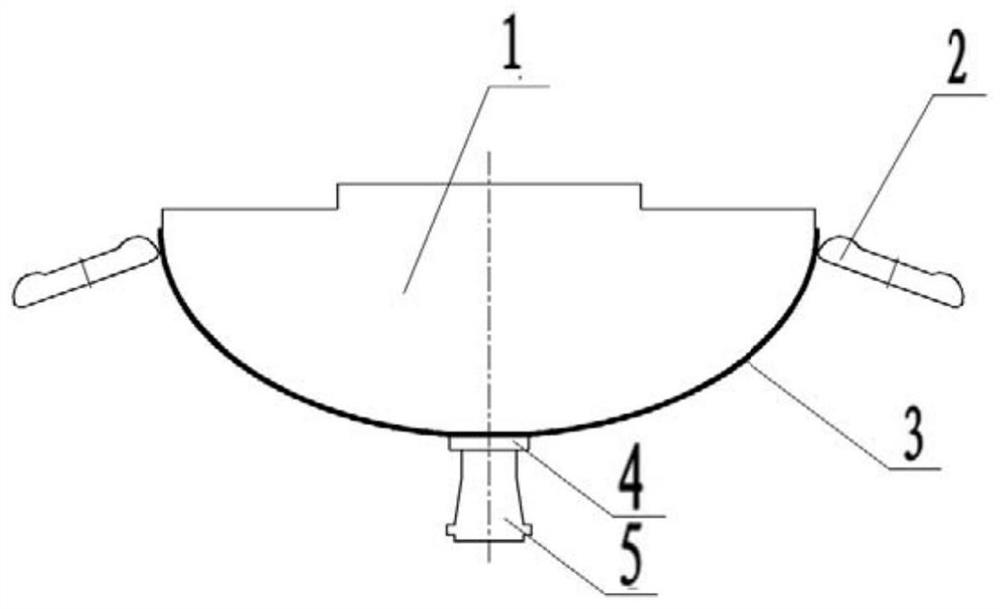

[0030] The selected material is the rough plate of 2219 aluminum alloy, its size is 3800×3800mm, the wall thickness is 30mm, the outer diameter of the large end of the ellipsoid bottom part is 3500mm, the height is 1200mm, and the wall thickness is 15-30mm.

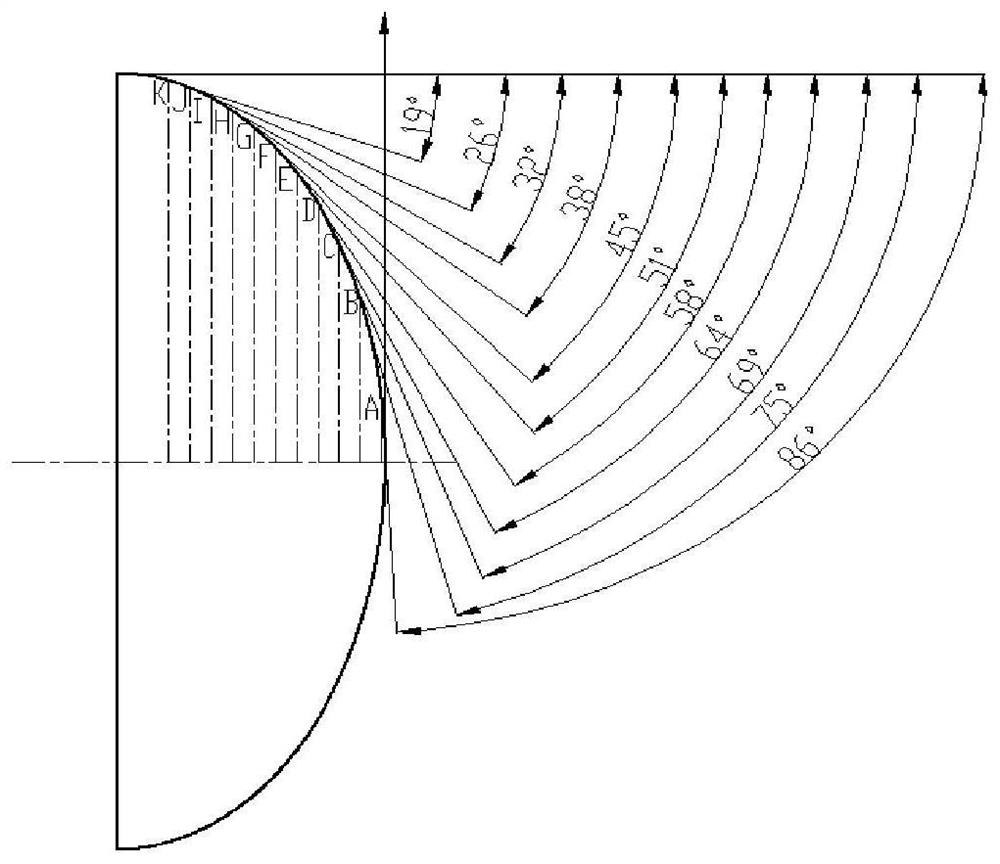

[0031] This embodiment provides a method for manufacturing a large thin-walled special-shaped curved surface member, including the following steps:

[0032] S1, blanking: use the gantry CNC milling machine to process the 2219 aluminum alloy square rough plate with a size of 3800×3800×30mm into a circular slab with a diameter of φ3700mm and a wall thickness of 30mm, and vacuum absorb the 2219 aluminum alloy through the pressure plate and other tooling and machine tools The square blank plate is fixed on the machine table, and the installation positioning hole 6xφ80mm and the hoisting hole φ40mm located in the center of the plate are processed, and the excess material of the plate is removed by milling to the required size a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com