Adjustable intelligent cooling water manufacturing and filtering device for continuous casting machine

A technology of intelligent manufacturing and filtering devices, which is applied in the direction of filtration separation, filtration loops, fixed filter elements, etc. It can solve the problems of frequent maintenance and replacement of filter devices, reduced production efficiency of production equipment, and filter elements without adjustment functions. Achieve the effect of shortening maintenance time, simple and convenient installation process, and reducing rhombus change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

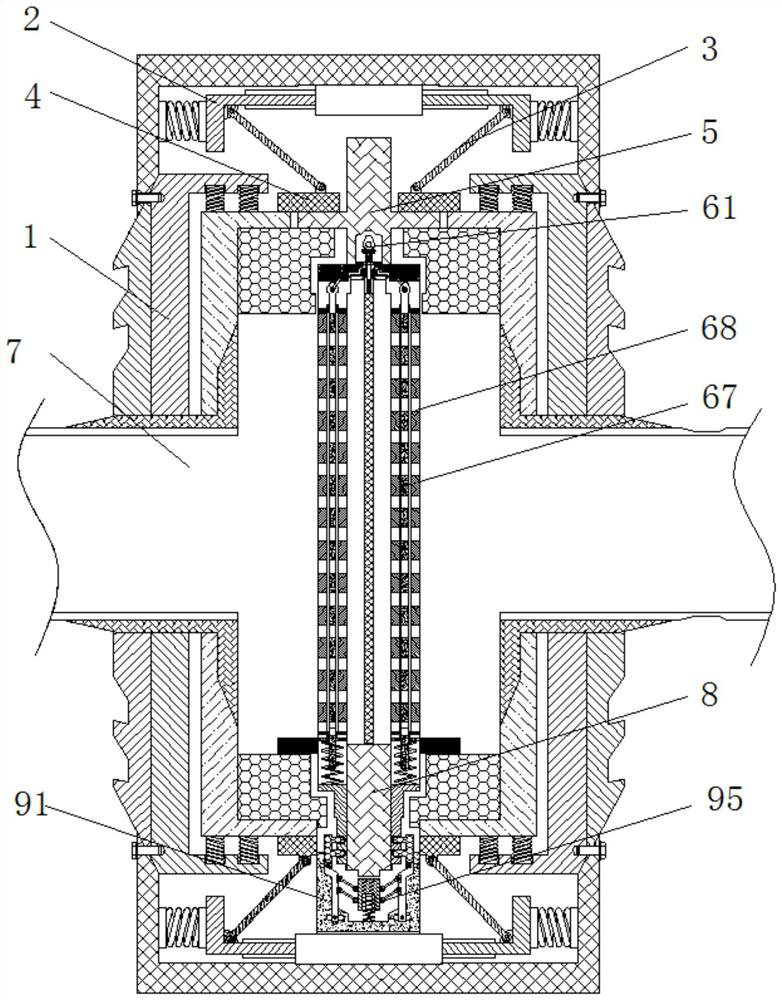

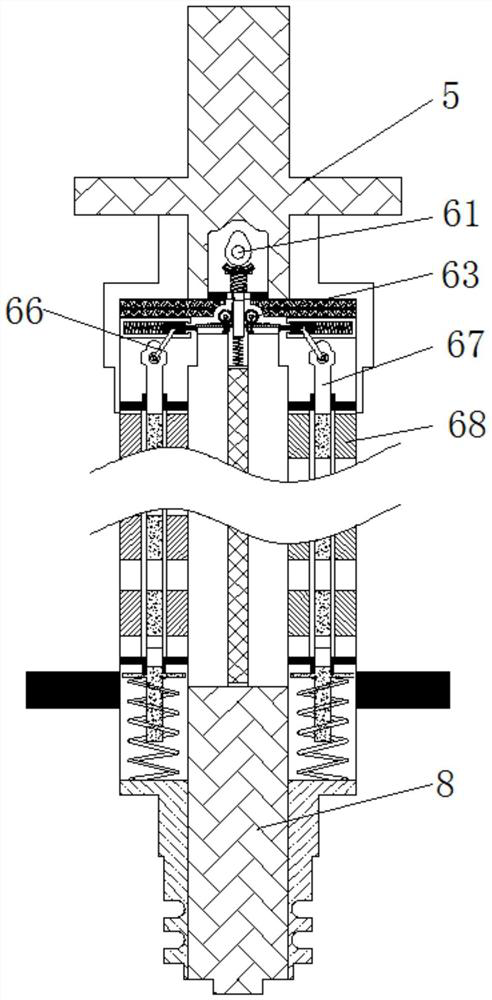

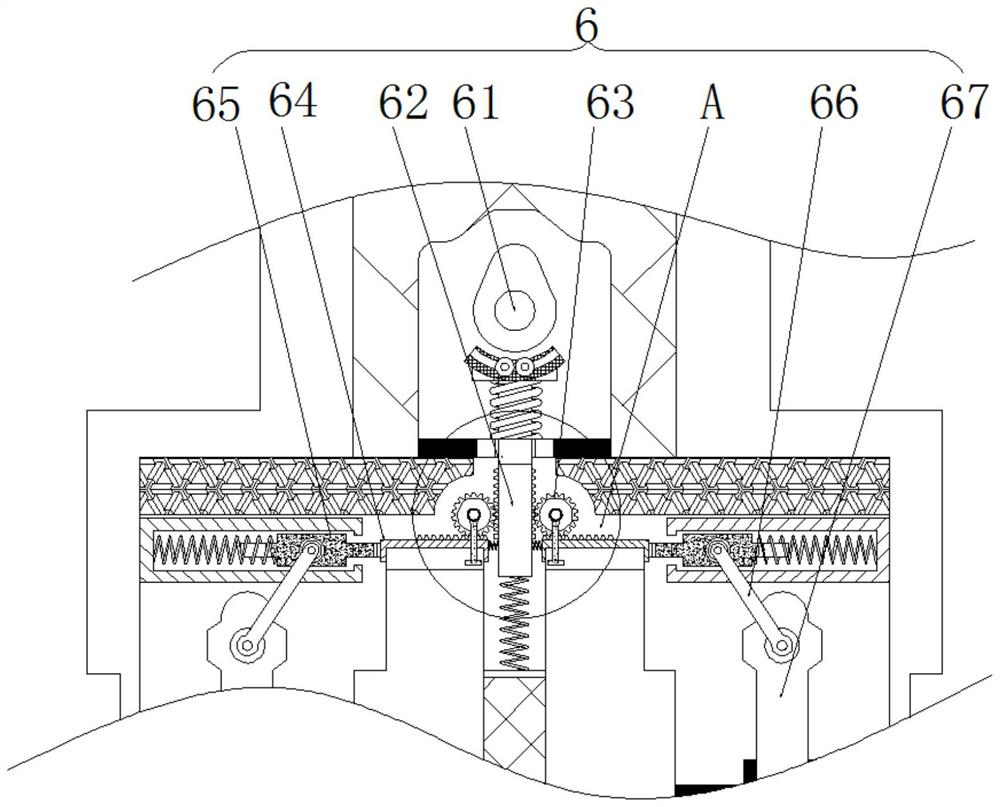

[0029] see Figure 1-4 , an adjustable intelligent manufacturing cooling water filter device for continuous casting machines, including an outer shell 1, a right-angle movable plate 2 is arranged on the inner top of the outer shell 1, and the right-angle movable plate 2 is provided with two groups of upper and lower groups, and each group is provided with a symmetrical There are two left and right, and a buffer spring is arranged between the outer side of the right-angle movable plate 2 and the outer shell 1, and a connecting groove is arranged in the middle of the left and right two right-angle movable plates 2. The bottom of the movable plate 2 is hinged with a diagonal tie rod 3, and the bottom of the diagonal tie rod 3 is movably connected with a compression block 4, and the bottom of the compression block 4 is movably connected with a filter element holder 5, and the bottom of the filter element holder 5 is movably connected with an adjustment assembly 6. Component 6 incl...

Embodiment 2

[0031] see figure 1 , Figure 5-6 , an adjustable intelligent manufacturing cooling water filter device for continuous casting machines, including an outer shell 1, a right-angle movable plate 2 is arranged on the inner top of the outer shell 1, and the right-angle movable plate 2 is provided with two groups of upper and lower groups, and each group is provided with a symmetrical There are two left and right, and a buffer spring is arranged between the outer side of the right-angle movable plate 2 and the outer shell 1, and a connecting groove is arranged in the middle of the left and right two right-angle movable plates 2, and one end of the inner side of the right-angle movable plate 2 is sleeved in the connecting groove, and the right-angle The bottom of the movable plate 2 is hinged with a diagonal tie rod 3, and the bottom of the diagonal tie rod 3 is movably connected with a compression block 4, and the bottom of the compression block 4 is movably connected with a filter...

Embodiment 3

[0033] see Figure 1-6, an adjustable intelligent manufacturing cooling water filter device for continuous casting machines, including an outer shell 1, a right-angle movable plate 2 is arranged on the inner top of the outer shell 1, and the right-angle movable plate 2 is provided with two groups of upper and lower groups, and each group is provided with a symmetrical There are two left and right, and a buffer spring is arranged between the outer side of the right-angle movable plate 2 and the outer shell 1, and a connecting groove is arranged in the middle of the left and right two right-angle movable plates 2. The bottom of the movable plate 2 is hinged with a diagonal tie rod 3, and the bottom of the diagonal tie rod 3 is movably connected with a compression block 4, and the bottom of the compression block 4 is movably connected with a filter element holder 5, and the bottom of the filter element holder 5 is movably connected with an adjustment assembly 6. Component 6 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com