Device for producing saccharicterpenin from camellia seed meal and method thereof

A technology of camellia oil seed meal and saccharoterpenoids, which is applied in the field of devices for producing saccharoterpenoids from oil camellia seed meal, can solve the problems of wasting manpower and low efficiency of producing saccharoterpenes, and achieves the effects of increasing extraction efficiency and speeding up reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

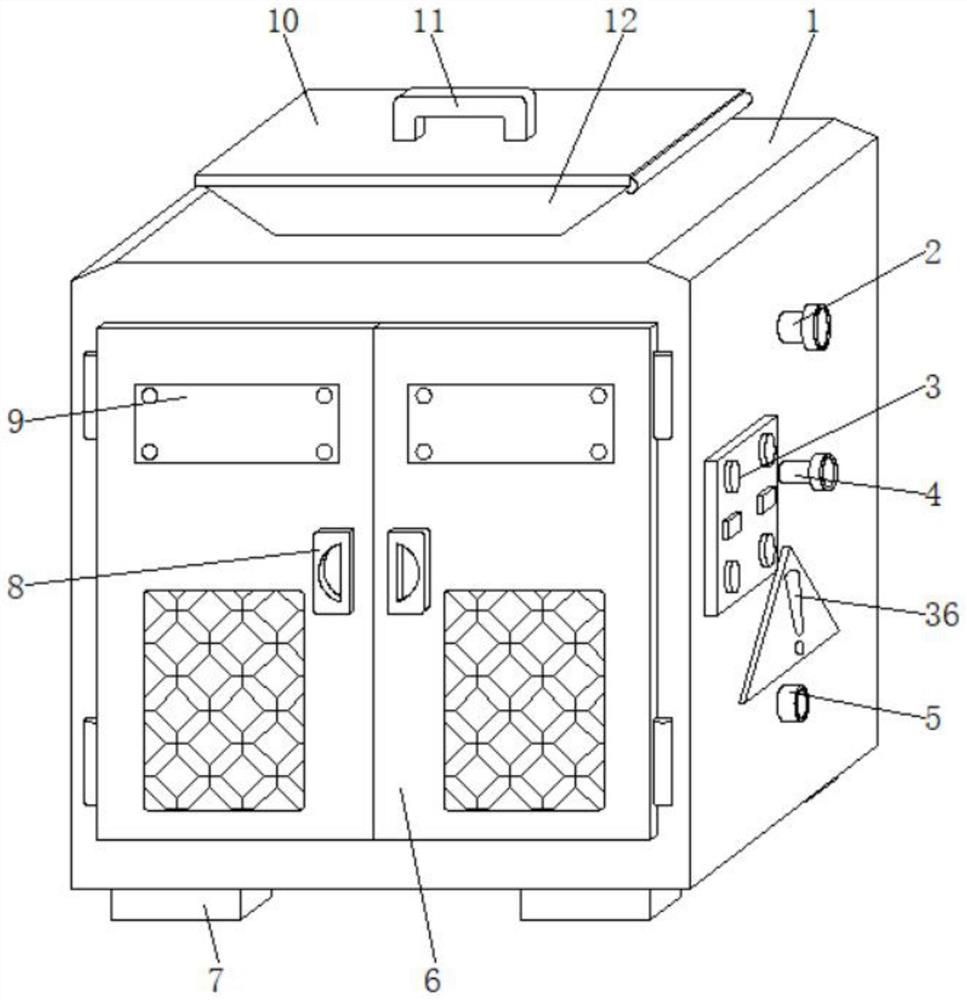

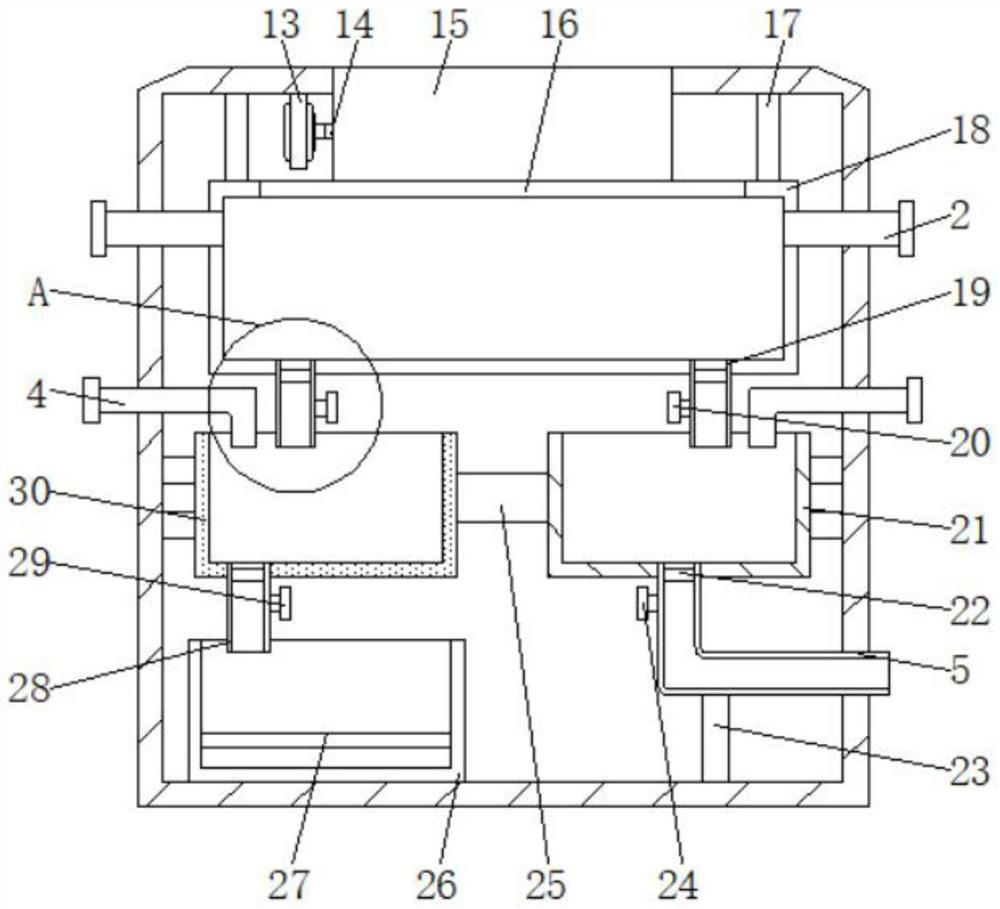

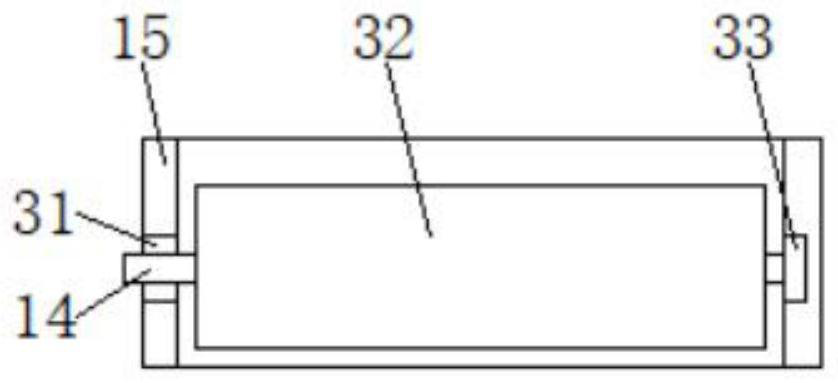

[0035] see Figure 1-7 , in this embodiment: a device and method for producing saccharoterpenoids from Camellia oleifera seed dregs, comprising a box body 1, the inner top wall of the box body 1 is fixedly connected with a motor 13, and the upper surface of the box body 1 is fixedly inlaid with broken Box 15, the inner wall of the crushing box 15 is fixedly inlaid with a first bearing 33, the left side of the crushing box 15 is fixedly inlaid with a second bearing 31, the output end of the motor 13 is fixedly connected with a rotating rod 14, and the right end of the rotating rod 14 is fixedly connected There is a crushing roller 32, the right end of the crushing roller 32 is fixedly connected to the inner ring of the first bearing 33, two sets of fixed rods 17 are fixedly connected to the inner top wall of the box body 1, and the bottom ends of the two groups of fixed rods 17 are fixedly connected with a heating Box 18, the upper surface of heating box 18 is provided with ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com