Device for improving digestion and absorption characteristics of high-moisture plant-based protein meat and method thereof

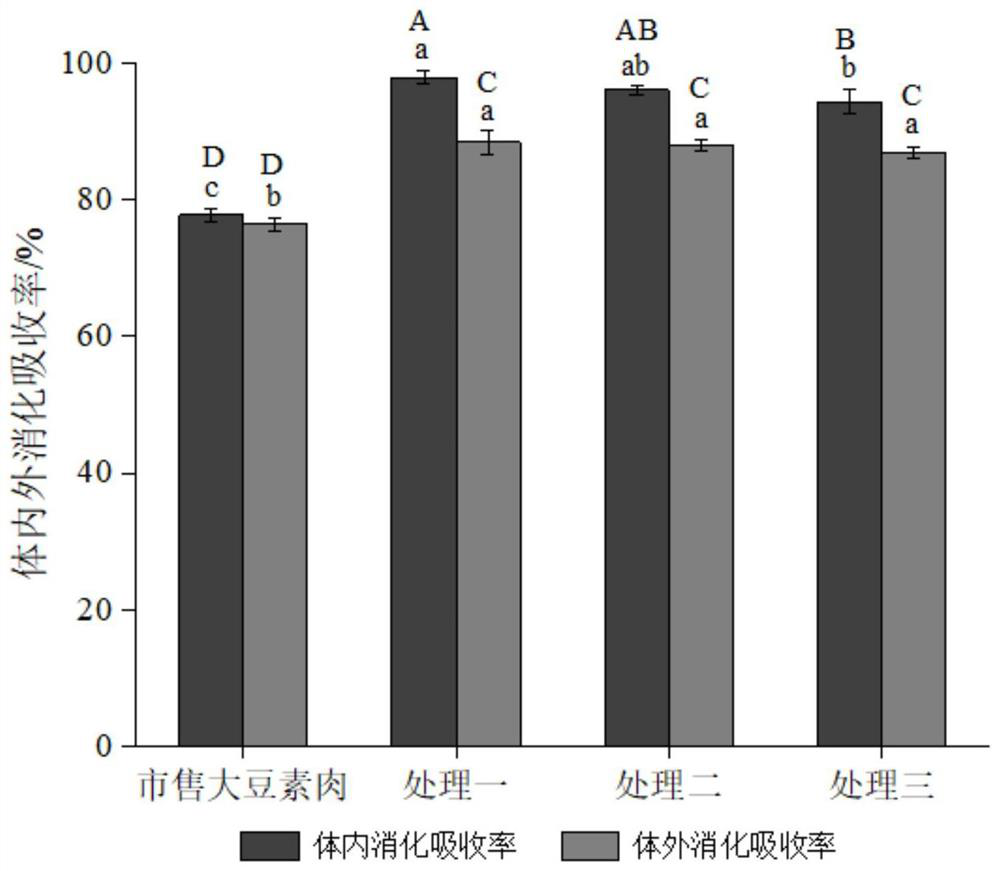

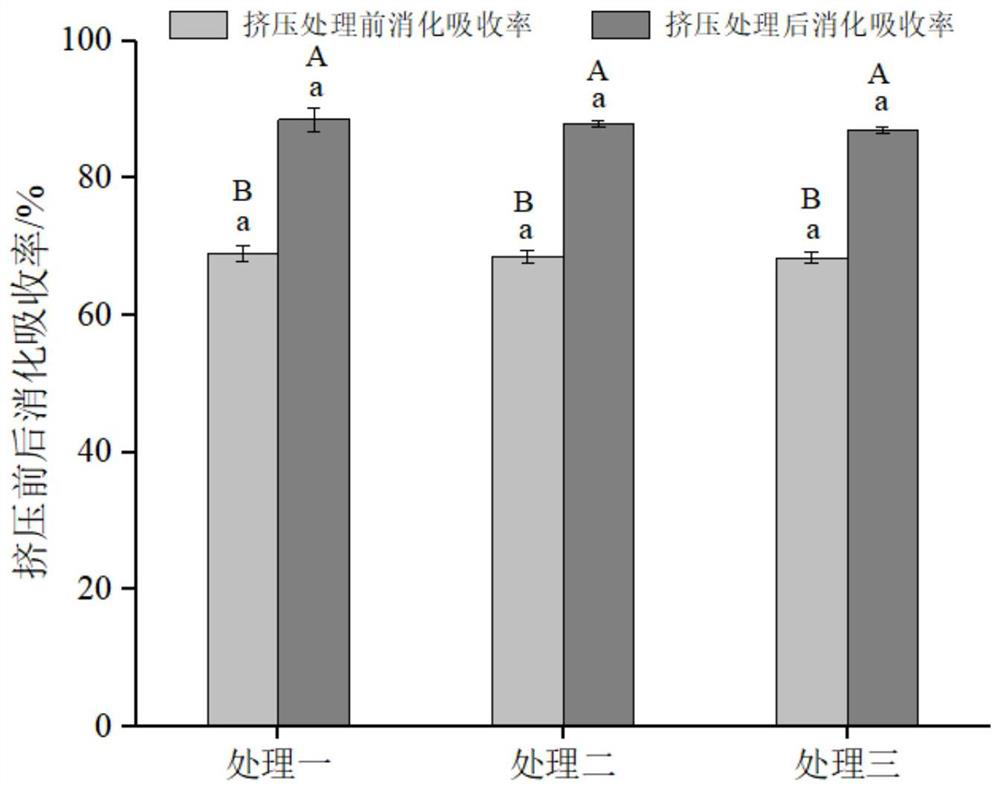

A technology for digestion and absorption of plant protein, applied in the direction of plant protein processing, protein food processing, protein food ingredients, etc., can solve the problems of low moisture content of plant-based protein meat, poor protein digestion and absorption, and achieve good product organization structure, The effect of improving the utilization rate of plant protein and solving the problem of indigestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

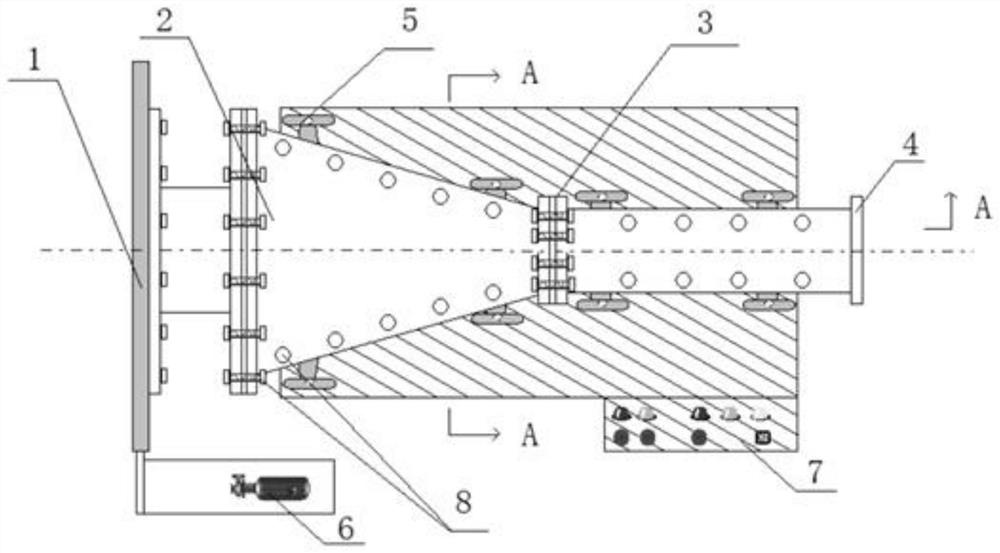

Method used

Image

Examples

Embodiment 1

[0056] Accurately weigh 40kg of soybean protein isolate, 35kg of gluten powder, 20kg of pea protein, 5kg of shiitake mushroom powder, 5kg of rice bran, 0.1kg of L-cysteine, 1kg of sodium chloride, and 0.01kg of titanium dioxide. Powder, pea protein, shiitake mushroom powder and rice bran protein are mixed evenly to make powder, add auxiliary materials L-cysteine, sodium chloride, titanium dioxide, the ratio of enzyme activity to plant protein substrate is 70U / g, add compound protease, mix evenly, The prepared solid material is injected into the feed port of the twin-screw extruder, and water is injected at the same time for extrusion treatment. The extrusion parameters are: the feeding speed is 8kg / h, the temperature in zone I is 40°C, and the temperature in zone II is 50°C, the temperature in zone III is 150°C, the temperature in zone IV is 160°C, the temperature in zone V is 45°C, and the screw speed is 200rpm / min.

Embodiment 2

[0058] Accurately weigh 40kg of soybean protein isolate, 35kg of gluten powder, 25kg of pea protein, 1kg of shiitake mushroom powder, 0.2kg of L-cysteine, 2kg of sodium chloride, and 0.02kg of titanium dioxide. Mix protein and shiitake mushroom powder evenly, add L-cysteine, sodium chloride, titanium dioxide auxiliary materials, the ratio of enzyme activity to vegetable protein substrate is 80U / g, add compound protease, mix evenly, and mix the prepared solid materials Inject into the feed port of the twin-screw extruder, inject water at the same time, and carry out extrusion treatment. The extrusion parameters are: the feeding speed is 10kg / h, the temperature in zone I is 45°C, the temperature in zone II is 55°C, and the temperature in zone III The temperature in zone IV is 155°C, the temperature in zone IV is 162°C, the temperature in zone V is 55°C, and the screw speed is 250rpm / min.

Embodiment 3

[0060] Accurately weigh 20kg of soybean protein isolate, 35kg of gluten powder, 45kg of pea protein, 10kg of rice bran, 9kg of shiitake mushroom powder, 0.3kg of L-cysteine, 3kg of sodium chloride, and 0.03kg of titanium dioxide. , pea protein, shiitake mushroom powder and rice bran protein are mixed evenly to make powder, add L-cysteine, sodium chloride, titanium dioxide auxiliary materials, the ratio of enzyme activity to plant protein substrate is 90U / g, add compound protease, mix evenly, and The prepared solid material is injected into the feed port of the twin-screw extruder, and water is injected at the same time for extrusion treatment. The extrusion parameters are: the feeding speed is 15kg / h, the temperature in zone I is 50°C, and the temperature in zone II is 60°C °C, the temperature in Zone III is 158 °C, the temperature in Zone IV is 165 °C, the temperature in Zone V is 70 °C, and the screw speed is 300 rpm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com